The transformation of hydraulic power into rotating mechanical motion requires hydraulic systems to use orbital motors. Users choose BMH and OMH orbital motors because they deliver maximum power output through reliable low-speed rotation in a small package. The relationship between torque and speed in hydraulic pump motors needs to be understood when picking the right motor for your application.

What Are BMH and OMH Orbital Motors?

The BMH and OMH orbital motors function as hydraulic gear motor that service agricultural, industrial, and mobile equipment. The motors function through Gerotor technology which uses two rotating gears to push fluid and create torque. Their basic design and strong performance qualities enable them to run without stopping in tough working conditions.

Torque and Speed Characteristics

The connection between torque and speed runs in opposite directions in orbital motors. The hydraulic motor operates according to a specific principle that lets more fluid flow boost speed but higher pressure builds torque.

- BMH Motors deliver good speed control and medium displacement performance in hydraulic systems that use moderate pressure.

- OMH motors generate stable torque throughout different workload types and pressure ranges up to their limits which proves useful with conveyor systems mixing tools and rotary brushes.

- BMH and OMH motors create strong force at slow speeds to meet construction and material handling system requirements.

Hydraulic Pump Motor Matching

The best performance of orbital motors requires matching them to proper hydraulic pump motors. The selected pump determines both system pressure levels and flow rates that directly control motor torque together with speed output. The company THM Huade Hydraulics provides customers with multiple hydraulic pump and motor options to match their specific system requirements

Applications and Advantages

The applications that use BMH and OMH motors extend across a wide range of industries.

- Agricultural machinery (e.g., harvesters, sprayers)

- The industrial equipment category includes conveyors and cutting machines among other items.

- Mobile machinery (e.g., sweepers, snow plows)

Advantages:

The size of these motors remains compact which makes them suitable for tight installation spaces.

High Torque: Exceptional low-speed torque performance.

The motors require minimal maintenance because their basic internal design increases durability and reduces wear.

The hydraulic motor offers competitive pricing which makes it cost-effective compared to alternative motor types in the market.

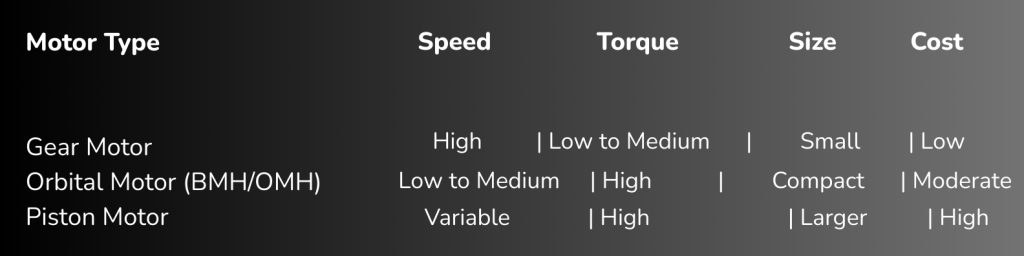

Hydraulic Motor Types Comparison

When selecting a motor, it’s helpful to compare hydraulic motor types:

The selection of gear motors would be ideal when you need a hydraulic motor that operates at high speeds. Applications that need both strong torque capabilities alongside controlled speed operation should select the BMH and OMH motors as their top choice.

THM Huade Hydraulics: Trusted Source for Quality Motors

Through its product line THM delivers dependable hydraulic products which include the BMH and OMH orbital motors. THM products provide their customers with exceptional performance together with durability and affordable pricing for various industrial applications. The product range of THM Huade includes both small mobile equipment motors and heavy machinery pump motors.

Conclusion

The selection process for hydraulic system solutions depends on your ability to understand how torque and speed connect in BMH and OMH orbital motors. These motors provide exceptional torque performance at low speeds making them appropriate for various applications because of their flexible motor compatibility alongside reliable operational characteristics. THM provides premium products together with comprehensive support for hydraulic motors that meet all performance requirements including heavy load operations and budget needs.

FAQs About BMH & OMH Orbital Motors

Q1: What distinguishes BMH motors from OMH motors is their primary operational difference.

The medium displacement range of a BMH motor features good speed regulation yet an OMH motor provides higher pressure capabilities and stronger torque output.

Q2: Are BMH and OMH motors reversible?

Both BMH and OMH motors operate in a bi-directional manner because their direction of rotation depends on hydraulic flow direction.

Q3: The usage of BMH or OMH motors is possible for continuous-duty applications.

Absolutely. The motors show specific design features for maintaining continuous operation in agricultural as well as industrial environments.

Q4: The selection of a suitable hydraulic pump for use with a BMH or OMH motor depends on which question.

The selection of a hydraulic pump must match both the flow rate and pressure specifications of the motor system. THM Huade Hydraulics offers compatible

The hydraulic pumps and motors operate with matched efficiency as a single system.

Q5: The standard pricing for hydraulic motors in BMH and OMH models can be found at what rate?

The motor prices depend on both displacement dimensions and pressure rating specifications. BMH and OMH motors provide equivalent torque output to piston motors at lower prices.

Q6: Are these motors suitable for compact systems?

These motors prove ideal for compact systems because they feature a small design which makes them classified as small hydraulic motor.