The hydraulic cylinder is important for operational activities like construction, steel manufacturing, cement production, machine tool operations, etc. However, you need to understand different hydraulic cylinder types to choose a suitable one for your machine or equipment. Choose poorly, and you’ll find yourself beset with breakdowns, unsatisfactory performance, and greater overall expense.

But how do you go about selecting the proper one? Here is all you need to know, from hydraulic cylinder types to critical factors such as power, seals, and pistons.

Hydraulic Cylinders: What You Need To Know

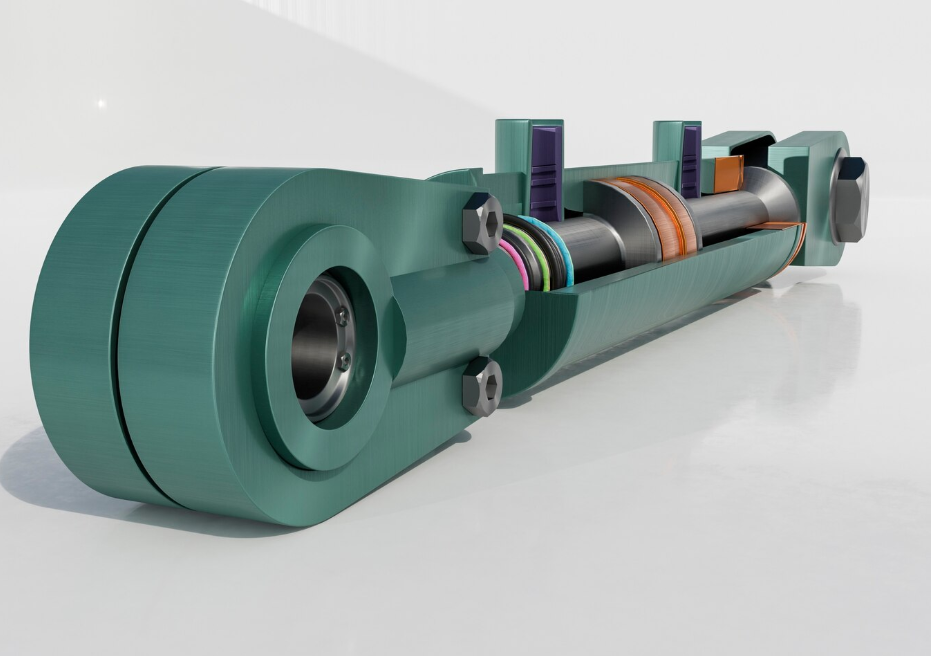

Hydraulic cylinders are devices that convert hydraulic energy into linear mechanical energy (i.e., force). They assist in pushing, pulling, lifting, or pressing materials. They are found in excavators, presses, injection molding machines, and many other machines. Although their role seems easy, their design has been far from that.

Selecting a suitable hydraulic cylinder ensures that your equipment runs efficiently and safely and increases its longevity.

Hydraulic Cylinder Types You Need to Know

There is no single type of hydraulic cylinder that is ideal for every job. Knowing this allows you to choose which type to select for your application.

Tie-Rod Cylinders

These are typically utilized in manufacturing equipment. Their easy maintenance and cost-effective nature make them feel like a heavenly energy source. Directing end caps using tie-rods; more suitable for light to medium-duty applications.

Welded Cylinders

The design of welded cylinders is compact. They’re made for heavy lifting. You mostly see them in industrial and mobile applications.

Telescopic Cylinders

Great for space-constrained operations. Telescopic designs provide longer strokes and are common in dump trucks and cranes.

Small Hydraulic Cylinders

As their name implies, small hydraulic cylinders are compact units. They are perfect for applications with limited space, like robotics and precision tools.

Key Components to Consider in Hydraulic Cylinders

While there are many things to consider when choosing the correct hydraulic cylinder, here are the essentials.

Hydraulic Cylinder Piston

The piston of the hydraulic cylinder moves forward and backward inside the barrel. It is the component that converts hydraulic power to mechanical motion. The size and design of the piston impact the cylinder’s efficiency and output force.

Check whether the piston is heavy-duty enough for your load. If it is too small, it can wear out quickly.

Hydraulic Cylinder Seals

The hydraulic cylinder seal stops fluids from leaking out. It helps maintain pressure and ensures that the operation runs smoothly. Cheap seals are prone to downtime and frequent maintenance. Always use seals rated for your application’s temperature and pressure.

Industry-Specific Applications

Construction

In the construction industry, equipment like excavators, loaders, and bulldozers relies heavily on welded body hydraulic cylinders. These cylinders are favored for their robust construction and compact form, making them well-suited to endure extreme conditions and handle heavy-duty operations.

Manufacturing

Tie-rod cylinders are commonly used in manufacturing environments due to their standardized design and ease of maintenance. Their modular structure allows for quick replacements and efficient repairs, minimizing downtime in fast-paced production settings.

Agriculture

Agricultural machinery such as tractors, sprayers, and harvesters often utilizes telescopic cylinders. These cylinders offer extended stroke capabilities while maintaining a compact footprint, making them ideal for farming tasks that require long reach and operate within space limitations.

Key Factors to Keep in Mind

A guideline for what to keep in mind with hydraulic cylinder selection:

Load Requirements: Know the amount of pressure required for the task. A discrepancy here could cause failure in the system.

Stroke Length: Use a cylinder with an adequate stroke length. If it is short, it will not perform its duty, and if it is too long, you will waste space and money.

Mounting Style: Performance varies with how the cylinder is mounted. Several styles are available, such as flange, trunnion, and clevis mounts. The choice depends on your machine’s architecture.

Operating Conditions: It all comes down to three things: temperature, environment, and exposure to elements.

Ideal for outdoor/dusty conditions: rugged cylinders with tailored protective coatings.

Speed Requirements: Different speeds are needed for different applications. The bore and rod size should be in proportion to the cylinder’s internal speed.

Application-Specific Tips

For Construction Equipment: Welded cylinders are chosen for their endurance. They are much better at handling shock and dirt. Good-quality hydraulic cylinder seals are required to prevent fluid leaks on-site.

For Steel and Cement Plants: Be ready for heavy-duty cylinders, depending on the situation. When evaluating pistons, isolate piston strength and seal quality.

Applicable to Plastic Injection Molding Machines: Precision is key here. Choose small and gentle hydraulic cylinders with little backlash.

For Machine Tool Manufacturers: Please keep it to tie-rod or small cylinders for easy reach and compactness.

Common Mistakes to Avoid

- Ignoring seals: Low-quality hydraulic cylinder seals translate to reduced functionality with more downtime.

- Not checking compatibility: Make sure the cylinder is compatible with your system.

- Sub-spec cylinder: In heavy-duty applications, a weak-kneed cylinder won’t survive long.

Final Thoughts

Selecting the correct hydraulic cylinder is more than just size or dollar figure. It is knowing your gear and what it asks of you. Every part, from the hydraulic cylinder piston to the seals, serves a purpose. Never skip the little stuff, like mini hydraulic cylinders in a tight machine.

Looking for the right hydraulic cylinder?

Check out THM Haude’s trusted range of high-performance hydraulic cylinders built for every application, big or small. Whether you need expert advice or a custom-built solution, THM Haude is your one-stop partner for quality and durability.

FAQs

How do I keep seals on hydraulic cylinders?

Check to see if the seals are cracked or leaking. Choose seals suitable for your machine's temperatures and pressure levels. This is important to avoid any issues afterward.

What does a hydraulic cylinder piston do?

The hydraulic cylinder piston translates hydraulic energy into motion. It pushes or pulls depending on the direction and pressure of the fluid.

How do I know when to change my hydraulic cylinder?

If you see regular leakage, it means that your hydraulic cylinder is bad for functionality and could stop working within a short time. Replace it before it gets broken. Aside from this, if a cylinder leaks, it should also be replaced.