Internal gear hydraulic pumps are utilized in various industries due to their efficiency, compactness, and versatility. If you are researching pump types & benefits or deciding where these units will fit in your system, knowing their fundamental characteristics and uses is important.

This post will discuss the various hydraulic internal gear pumps, their differences, benefits, and common applications across various industries.

What is a Hydraulic Internal Gear Pump?

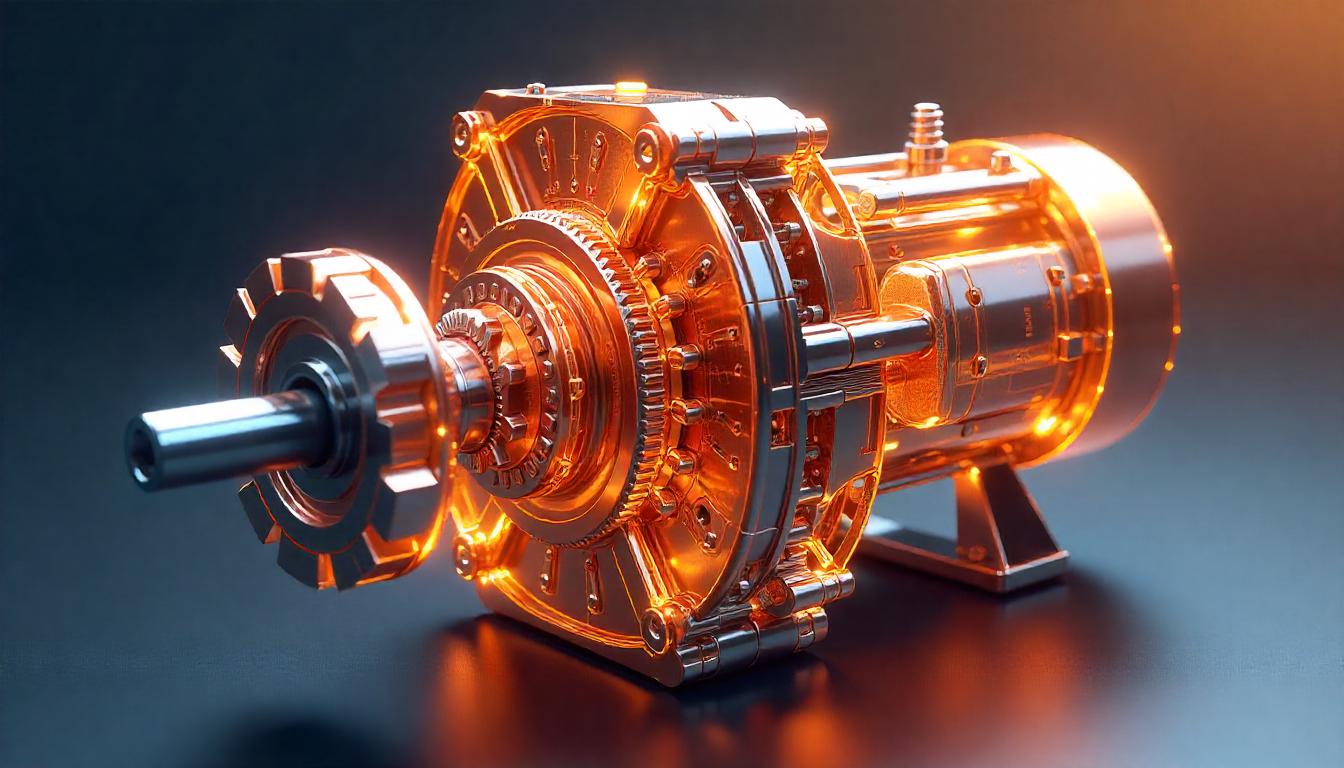

A hydraulic internal gear pump is a type of positive displacement pump designed to pump hydraulic oil through a system consisting of two interlocking gears. It consists of an inner (drive) gear and an outer (driven) gear, both of which rotate within an operating case. The inner gear eccentrically mounts and internally meshes with the outer gear.

A crescent-shaped seal, placed between the gears, divides the suction and discharge sides. As the gears rotate, it opens up the cavities that draw in fluid. The liquid then circulates around the casing and is pushed out through the outlet as the cavities contract. This design provides:

- Smooth, pulse-free flow

- High efficiency at varying pressures

- Great capability to handle a wide range of fluid viscosities

Due to these features, hydraulic internal gear pumps are used in a wide range of systems, including continuous pressure and quiet operation systems in industrial machinery, mobile equipment, and chemical processing.

Types of Hydraulic Internal Gear Pump

Internal gear pumps operate using two gears: the external rotor and the internal idler gear. They are constructed in a way that allows for smooth and continuous fluid movement. Let’s look at some of the most commonly used types:

Standard Internal Gear Pumps

These pumps have a straightforward and effective design, consisting of only a rotor, idler, and a crescent-shaped divider. The fluid enters the pump, gets trapped between the gears, and is pushed out through the discharge port.

They’re designed to transfer high-viscosity liquids, such as oils, resins, and fuels.

Reversible Internal Gear Pumps

Reversible gear pumps offer bi-directional flow, allowing the same pump to transfer fluid in either direction. This eliminates the need for multiple pumps for reverse and forward fluid in-and-out. They are widely utilized in mobile hydraulic applications and automated machine operations.

Jacketed Internal Gear Pumps

In a process where fluid viscosity may vary with temperature, jacketed pumps ensure the fluid maintains consistency between the pump and the dispense head. They use thermal jackets to circulate steam or cooling agents around the pump casing. Industries such as food processing, petrochemicals, and pharmaceuticals benefit from this design.

Sealless (Magnetically Driven) Internal Gear Pumps

Designed for leak-free operation, these pumps use a magnetic coupling instead of a traditional shaft seal. This makes them suitable for hazardous, corrosive, or reactive fluids. You’ll see them in chemical processing, medical equipment, and hazardous material handling.

Advantages of Hydraulic Internal Gear Pump

Internal gear pumps offer several technical and practical benefits, making them a preferred choice in hydraulic systems. Below are some key advantages.

Smooth and Consistent Flow

Internal gear pumps produce a pulse-free flow, making them suitable for applications requiring high precision. Their uniform discharge rate supports stability in pressure-sensitive systems.

Wide Fluid Compatibility

These pumps manage a wide range of fluid viscosities from clear chemicals to thick greases. It is what makes them versatile across sectors.

Low Noise and Vibration

Thanks to their internal design, these pumps operate quietly with minimal vibration. This improves workplace comfort and reduces wear on connected components.

Self-Priming Capability

Unlike pumps that may require manual priming, internal gear hydraulic pumps have the ability to evacuate air from the suction line, allowing them to begin pumping immediately. It makes the startup of the system easier and downtime shorter.

High Efficiency with Compact Size

Even with a small size, the pumps offer high volumetric efficiency. They do a great job of working in tight spaces while still maintaining excellent flow characteristics.

High Efficiency with Compact Size

Internal gear pumps have fewer moving parts compared with other positive displacement pumps. This makes them easier to service and maintain over time, especially in systems with frequent maintenance cycles.

Gear Pump Applications Across Industries

Internal gear pumps are highly flexible and efficient, due to their advanced design applications. Here is where they are most obviously in play:

Hydraulic Systems

Due to their reliable pressure and flow characteristics, internal gear pumps dominate mobile and industrial hydraulic systems. They are reliable for continuous operation, given their compact build and efficiency.

Oil and Gas Industry

These pumps are frequently used to transfer crude oil, fuel, and lubricants. This is particularly useful for managing fluids of high viscosity at high pressure.

Food and Beverage Processing

The jacketed gear pumps handle temperature-sensitive products such as oils, syrups, and dairy products. Their gentle flow avoids foaming or product damage during transfer.

Chemical and Pharmaceutical Industries

They are suitable for transferring acids, solvents, and other reactive materials because they are leak-proof and do not corrode.

Paints and Coatings

Internal gear pumps ensure a steady and homogeneous conveyance of viscous materials such as paints, adhesives, and coatings, which helps in keeping the product stable and quality intact.

Conclusion

Having knowledge of what makes hydraulic internal gear pumps unique can enhance your decision-making process. These long-term advantages with respect to industrial use are due to their pulseless working, capacity to effectively handle a variety of fluids, and a minimal maintenance needs. When selecting a pump, consider fluid properties, system pressure, and operating conditions to ensure the most suitable choice. If you ensure that your selection aligns with these points, you will obtain the maximum value for internal gear pumps.

Frequently Asked Questions

What are the key advantages of using internal gear pumps?

Some major advantages are smooth flow, high efficiency, quiet operation, and compatibility with a wide range of viscosities. They’re also self-priming and easy to maintain.

Where are internal gear pumps commonly used?

Gear pump applications span across hydraulic systems, food and beverage processing, chemical plants, pharmaceuticals, and oil transfer. They’re chosen for reliability and precision in fluid handling.

How does an internal gear hydraulic pump work?

It uses an inner and outer gear to move fluid. As the gears rotate, fluid is drawn in, trapped between the gears, and pushed through the outlet, delivering a consistent, non-pulsating flow.

Is a hydraulic internal gear pump suitable for high-viscosity fluids?

Yes, a hydraulic internal gear pump is ideal for thick fluids like oils, resins, and adhesives. Its design allows it to handle high-viscosity liquids without compromising flow efficiency.