A load sensing proportioning valve is a crucial component of many hydraulic and braking systems. This component helps in ensuring that the pressure is distributed according to real-time load demands. This proportioning valve adjusts breaking force or hydraulic flow in response to changing weight or load conditions in trucks, trailers, or heavy machinery. In addition, this improves safety and control and extends the life of hydraulic components.

However, to get the most out of this system, proper load sensing proportioning valve adjustment is important. Inaccurate settings can lead to poor performance, safety issues, or excessive wear of parts. In industries adopting hydraulic load control, or with the growing focus on efficiency, responsiveness, and automated systems, knowing how to tune this valve can significantly improve operational reliability.

In this blog, we will explore how the valve works, why adjustment matters, and how to make precise adjustments for optimal performance. So let’s get started.

What Is A Load Sensing Proportioning Valve?

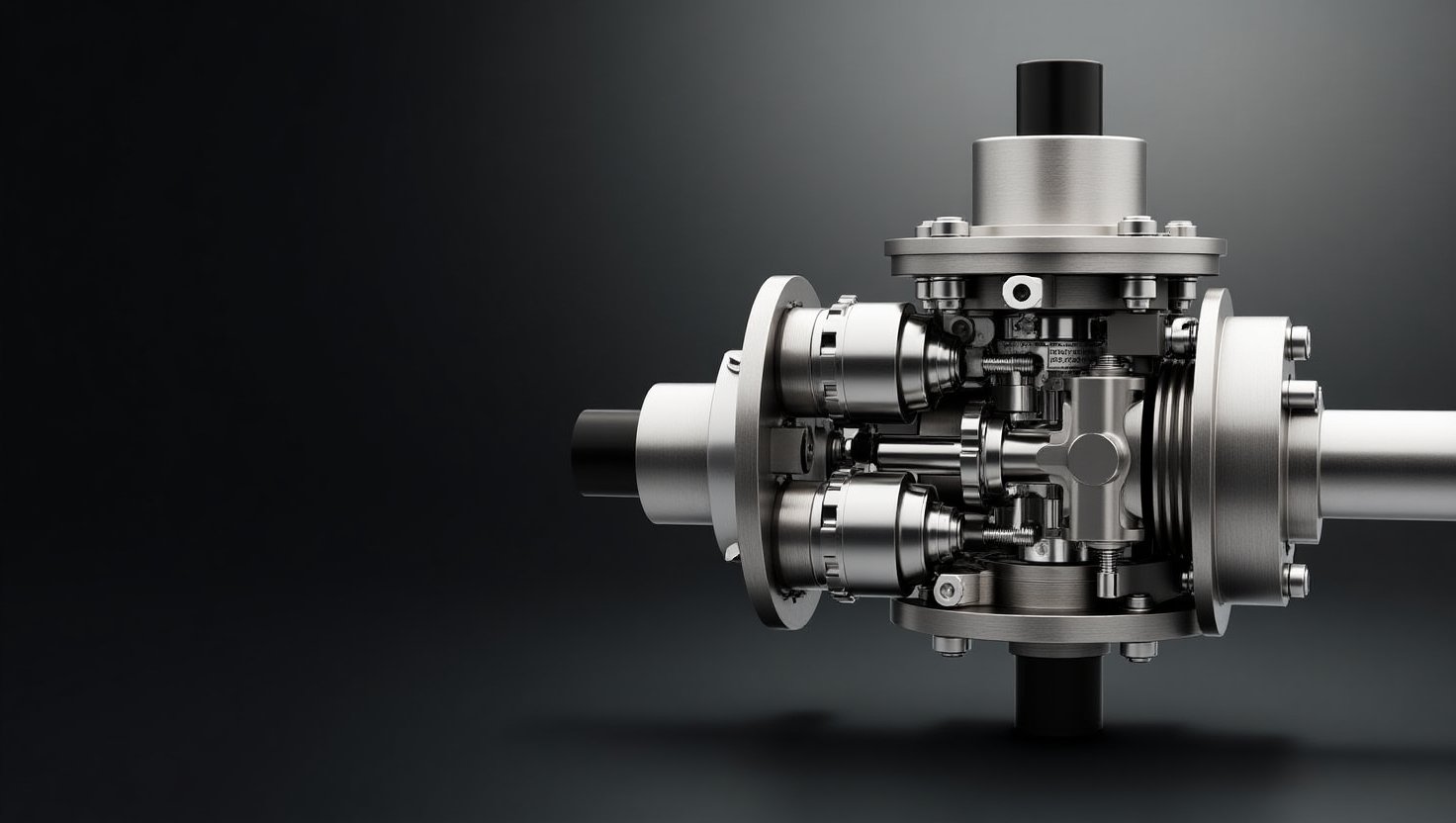

A load sensing proportioning valve is an important hydraulic part used in automotive and industrial systems to regulate brake pressure based on different loads. It enhances braking performance and safety by adjusting the force applied to the wheels, depending on the load carried.

The LSP valve performs two key functions:

Load Sensing: It detects axle load and adjusts pressures to prevent wheel lock-up under heavy loads.

Proportioning: It balances hydraulic brake pressure between the front and rear wheels to ensure stability.

LSPV supports more control stops and improved hydraulic load control by adapting brake force to changing conditions.

Some common applications of load sensing valves include trucks, trailers, and heavy machinery in construction or agriculture. Most valves operate through a mechanical and hydraulic linkage that reacts to load changes and adjusts fluid flow accordingly. Accurate load sensing proportioning valve adjustment is essential for safe, efficient braking performance under diverse conditions.

Why Load Sensing Proportionate Valve Adjustment Matters

The load sensing proportioning valve must be properly adjusted to ensure the optimal performance of the hydraulic system. The smooth performance of this valve involves adjusting flow rates and pressure settings to meet specific needs. This not only enhances system efficiency but also improves safety and ensures hydraulic load control.

Proper load sensing proportion valve adjustment is important as it directly affects how braking and hydraulic force is disturbed based on real-time load conditions. In vehicles, incorrect adjustment of the valve can lead to brake imbalance, which can cause premature wear, reduced stopping power, or loss of control. Moreover, it can also cause poor calibration, which may result in energy waste, system instability, or equipment damage.

LSPVs are designed to allow a high degree of flexibility by supporting precise hydraulic tuning. This helps operators to optimize settings based on current load demand, operating environment, and system behavior. This ensures smoother operation, better responsiveness, and long-term reliability.

Step-By-Step: Load Sensing Proportioning Valve Adjustment

Proper load sensing proportioning valve adjustment is crucial to maintaining precise braking performance and reliable hydraulic load control. Here is a step-by-step guide that you can follow to adjust the valve accurately:

Step 1: Locate The Valve

Identify the load sensing proportioning valve in your system. It is typically found near the rear axle, integrated into the hydraulic circuit of the machine.

Step 2: Inspect The Linkage

Check the mechanical and hydraulic linkages connected to the valve. Make sure it moves freely and shows load changes accurately.

Step 3: Evaluate Adjustment Requirements

Determine the manufacturer’s specifications for pressure and flow settings. To assess the current system behavior under load, use pressure gauges.

Step 4: Make Adjustments

Adjust the valve using the right screw or knob. Changes should be incremental. For increased load, increase the pressure output gradually.

Step 5: Test Under Load

Run the system with varied loads and monitor braking response on hydraulic behavior. Balance the valve as needed for balanced performance.

Step 6: Recheck And Secure

Make sure all parts are secure and test again to confirm consistent results.

Note: Make sure you correctly adjust the valve to ensure safe operation and better overall efficiency in load-responsive systems.

Common Mistakes To Avoid

Mistakes during adjustment can affect the overall performance of the hydraulic system. Here are some of the common errors to avoid:

- Don’t over-adjust the LSPV. It can restrict flow or cause erratic behavior under load.

- Always check pressure ratings and manufacturer settings.

- Don’t adjust blindly. Carefully monitor pressure and system performance first.

- Improper tools can damage valve parts or lead to incorrect settings.

- Don’t forget to test the valve under load.

Conclusion

Proper adjustment of a load sensing proportioning valve is essential for maintaining balanced pressure, improving hydraulic load control, and extending system life. You can enhance safety, reduce wear, and ensure more consistent performance of your hydraulic system by understanding how an LSPV works and adjusting it correctly.

If you are looking for reliable hydraulic solutions, then visit THM Huade today. Here you can explore precision-engineered load sensing valves and hydraulic components that are trusted by industries worldwide.

Frequently Asked Questions

How does a load sense valve work?

The load sensing controller responds to the increase in load pressure by slightly increasing pump flow and shows that pressure upstream of the directional valve increases by the corresponding amount. This keeps the pressure drop across the directional valve, which keeps the flow constant.

How do you adjust an LSPV?

When adjusting the LSPV, you increase or decrease the preload on that spring by pressing on the piston. More spring preload allows more line pressure before the valve closes and proportioning begins.

How to recentre the proportioning valve?

Press the brake pedal three times, with even, gentle pressure, until the pedal is applied as far as it can go. That will recentre the valve, and your proportioning valve reset will be complete.