Among fluid handling technologies, internal gear pumps offer high-precision, energy-efficient, and reliable solutions across a wide range of applications. Unlike the drum kits and lead guitars of other industrial sectors, these pumps are the workhorses of modern industry, driving critical applications in the chemicals, oil & gas, food processing, pharmaceuticals, and more.

Internal gear pumps are influential hydraulic components, and understanding how they work is essential for design engineers, plant operators seeking long-term solutions, and procurement experts evaluating next-gen pumping technology.

This guide covers the basics, benefits, working principle, applications, and selection criteria of internal gear pumps, helping you make a more informed decision.

What Are Internal Gear Pumps?

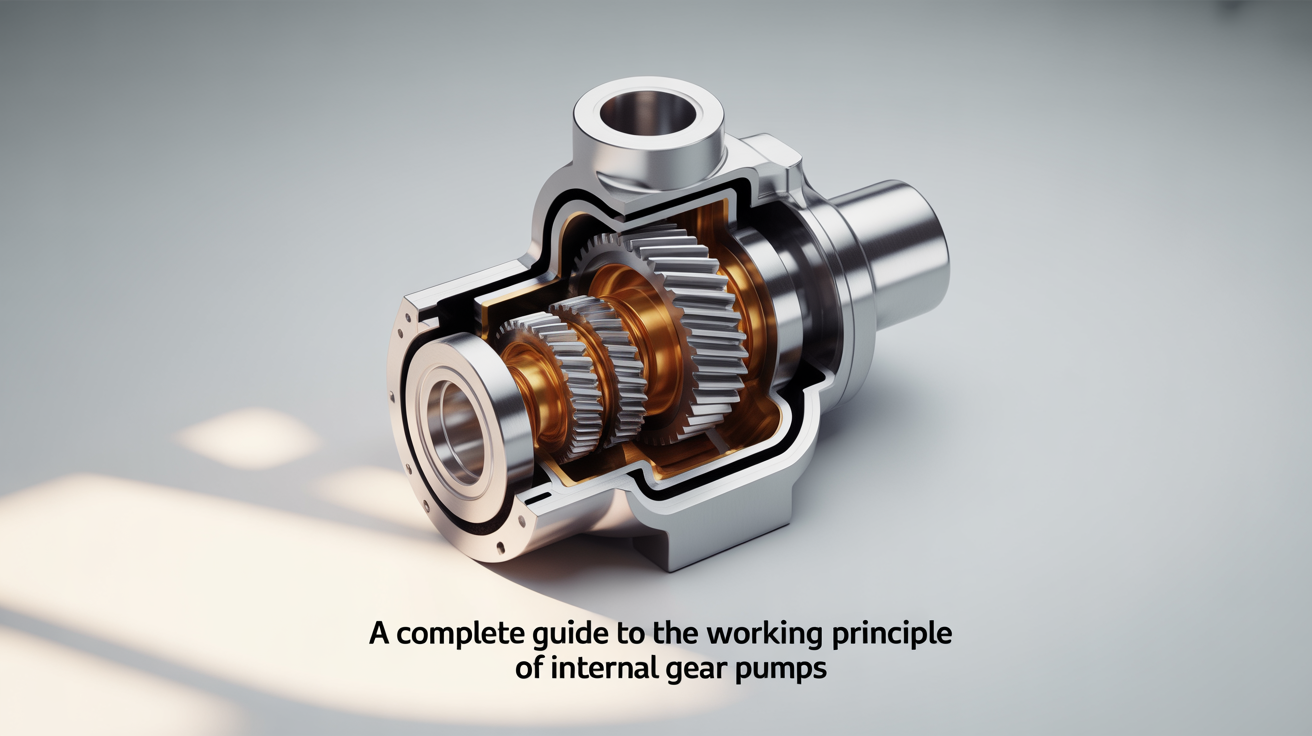

An internal gear pump is a positive displacement pump that moves viscous fluids in a controlled and precise manner. They consist of two meshing gears: an internal (or rotor) gear and an external (or idler) gear housed within a casing. The gears rotate in precise tolerances, creating sealed cavities that convey the fluid in a smooth, steady, and efficient fashion.

Unlike centrifugal pumps, which depend on the conversion of velocity to pressure, internal gear pumps displace a fixed volume of fluid per rotation, providing a constant flow rate even with varying pressures.

Internal Gear Pump Working Principle

The functionality of the internal gear pumps starts with the gear setup. Here’s how the internal gear pump works:

Suction Phase

With the pump shaft, the inner rotor gear, mounted eccentrically to the casing, rotates. This movement turns the outer idler gear in the opposite direction. At the inlet side, as the gears unmesh, they form cavities that grow in volume. This expansion creates a vacuum that pulls fluid into the pumping chamber.

Fluid Transfer

The oil is captured in the void between the gear teeth and the casing. These pockets of liquid are transported around the inner walls of the casing, not through the gear teeth, which allows for a smooth and pulse-free flow.

Discharge Phase

The fluid is then discharged when the meshing of rotating gears takes place on the discharge side, and it is pushed out of the pump chamber. Due to the close clearance of the gears, the backflow is small, and the discharge is efficient.

This is a continuous and closely controlled process in which internal gear pumps are well suited for precise dosing, metering, and also high-viscosity applications.

Why Choose Internal Gear Pumps?

In return, the structural design of internal gear pumps provides them with a number of performance advantages, which cement them as the top-of-the-line option for several industries:

High Volumetric Efficiency

This construction provides tight tolerances and sealed cavities for consistent flow with minimal leakage.

Smooth, Non-Pulsating Flow

The gear mechanism yields continuous output; this is especially important for applications that involve blending, lubrication, or dosing.

Self-Priming Capability

Internal gear pumps can evacuate air and start without external priming, reducing start-up complexity.

Works with a Variety of Fluids

They can cope with different viscosities from thin solvents to thick resins or bitumen.

Bi-Directional Operation

When properly ported to allow for reverse flow, which internal gear pumps can do. Internal gear pumps allow flexible design orientations.

Uses of Industrial Internal Gear Pumps

Industrial internal gear pumps have gained much use in demanding environments because of their versatility and efficiency. They perform exceptionally well in several key industries.

Chemical Transfer: For safe and accurate transfer of acids, polymers, and additives.

Oil & Gas: Suitable for lube oil systems, fuel transfer, and hydraulic fluids.

Food & Beverage: For chocolate, syrups, edible oils, and flavoring agents; FDA-compliant models

Paints & Coatings: Provides precise dosing of pigments, resins, and solvents.

Pharmaceuticals: It is used in sterile and hygienic processes, which include the preparation of ointments, suspensions, and other viscous formulations.

A notable consideration is that if the nature of your application requires accurate flow, high capacity to withstand harsh chemicals, and stability for long durations, then internal gear pumps are among the top choices you can make.

How to Select the Right Internal Gear Pumps

Choosing the appropriate pump requires a consideration of operational needs and environmental restrictions. So, what to look for while investing in the best internal gear pump?

Fluid Viscosity and Temperature

Select material and tolerances appropriate for your fluid. Viscosity plays a role in flow rate and power consumption, whilst temperature relates to seal integrity and efficiency.

Flow Rate and Pressure

Define your maximum and minimum operating ranges. An oversized pump wastes energy, while an undersized one risks cavitation and damage.

Pump Materials

The material must resist corrosion, abrasion, and chemical attack. This can include options such as stainless steel, cast iron, or specialized alloys, depending on the media.

Seal Type

Choose the right sealing configuration: mechanical seal, packing seal, or magnetic drive to avoid incursion of vapor and pollutants.

Mounting and Drive Options

If your layout and performance requirements allow, choose direct-coupled, gear-reduced, or motor direct-driven.

A reliable manufacturer can simplify the selection process and ensure you receive the right pump, backed by post-purchase support.

Final Thoughts

Some mechanical devices embody elegance in both design and function — simple yet powerful, compact yet highly efficient. The internal gear pump’s working principle is one such device.

Whether you are designing a new fluid system or upgrading an existing plant, investing in the best internal gear pump can result in reduced operating costs, improved safety, and an improvement in product quality.

For performance and precision you can trust, choose a brand that stands for engineering integrity and cutting-edge technology. THM Huade provides a more advanced series of industrial internal gear pump integrating innovation, manufacturing, and reliability.

Visit THM Huade to browse the range and supercharge your operations with one of the leading internal gear pumps in the global market.

FAQs

Q2: Can you use an internal gear pump for a fluid with an abrasive or particle count?

Internal gear pumps can tolerate mildly abrasive media in small amounts; they are designed to work on the clean side or filtered side of things. Too much, however, can lead to premature wear. If need be, special hardened components can assist.

Q3: Do internal gear pumps have a dry running?

No. While they are self-priming, doing so for extended periods can damage seals and gears. The fluid must be present before you turn it on.

Q 4: What is the Internal Gear Pump maintenance frequency?

Internal gear pumps, when installed correctly and with compatible fluids, can have thousands of hours of run time with minimal maintenance. The seals, wear plates, and alignment should be inspected every few months.