Workers from the construction, steel, cement, and plastics industries consider hydraulic systems as essential components. Every press device, including the press machine, CNC press brake, baling devices, and injection moulding equipment, needs reliable execution. Servo motor hydraulic pumps achieve their function in the applications.

The systems provide better control functions that also deliver enhanced system reliability along with improved energy efficiency. The adoption of servo-driven hydraulic technology demonstrates its importance throughout North American and Canadian industries because of its superior precision control and energy efficiency.

Let’s break down how a hydraulic servo system can enhance your operations.

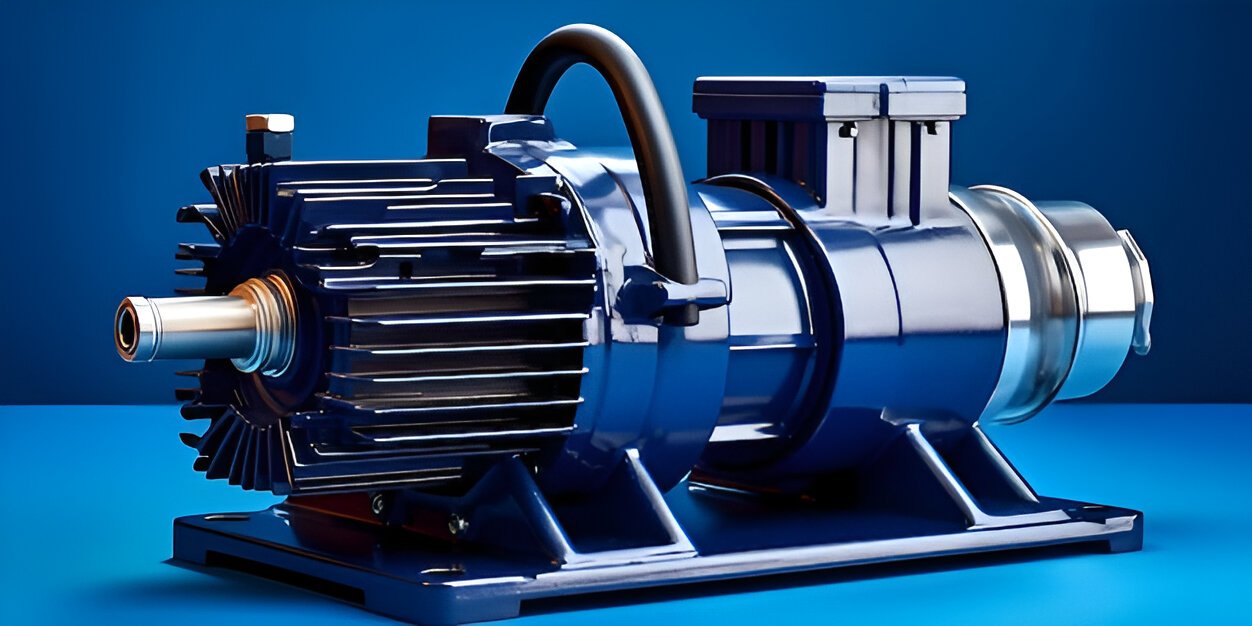

What Is a Servo Motor Hydraulic Pump?

Servo motor hydraulic pumps transmit power from a servo motor to operate the hydraulic pump mechanism. The system design enables accurate flow rate and pressure regulation of hydraulic fluid. This system activates the pump during required usage which minimizes both power consumption and engine heat generation.

Servo systems appear as essential components of both electro-hydraulic servo drives along with hydraulic servo control systems. Such technologies prove best when used for industrial applications which need adjustable speed and pressure controls.

You’ll find servo hydraulics in:

- Plastic injection molding and blow molding machines

- CNC press brakes

- Baling presses

- Die casting machines

- High-tonnage presses

- Machine tools

Advantages of Servo Motors in Hydraulic Pumps

1. Precision Control That Enhances Output

Servo hydraulic systems achieve precise motion control which presents one of their most important advantages.

The traditional setup makes the pump operate perpetually during operation. A servo motor controls both its speed and torque output through variations in the load conditions. The system delivers pressure and flow only to the precise levels needed which exceeds or goes below either measure.

Quality consistency in plastic injection molding machines requires exact pressure control and flow management according to producers. Using servo motors allows you to achieve higher control of your process through precise control of repeatability and faster cycle times.

2. Significant Energy Savings

Energy efficiency isn’t just a nice bonus anymore—it’s essential. With a servo motor hydraulic pump, you can cut energy use by as much as 50 to 70% compared to traditional systems. That’s because the motor only runs when your machine needs it. No constant running, no wasted power.

This not only reduces idle energy consumption but also means you won’t need an oversized cooling system. And yes, it helps shrink those electricity bills too.

If you’re operating heavy-duty machines like CNC press brakes or baling presses, these savings really add up over time.

3. Lower Noise Levels Improve Workplace Safety

Traditional hydraulic systems generate constant noise due to the pump running continuously. Servo-driven systems, however, are much quieter.

This not only improves the working environment but also meets increasing regulations for noise control in industrial settings. For operators and technicians, it means a safer and more comfortable workspace.

In sectors like construction equipment manufacturing, where multiple machines run simultaneously, this quieter operation adds real value.

4. Less Heat Generation, Lower Cooling Costs

Hydraulic systems naturally produce heat. But with Hydraulic Servo Motors, less energy is wasted as heat.

Since the motor runs only when needed, the system stays cooler. This reduces the demand on your oil cooler and extends the life of seals and hydraulic fluid.

If you’re operating in high-load environments such as steel plants or cement factories, that thermal efficiency can mean fewer breakdowns and longer service intervals.

5. Compact Design with High Power Density

Servo motors maintain their capability while remaining small in size. The motors deliver exceptional output torque even at low operational speeds, because of which they produce compact systems.

The compact size makes this technology perfect for equipment producers who need to integrate strong hydraulic mechanisms into confined areas. The product has high-performance capabilities without requiring extra space because of its compact design.

The effective use of space affects current machine tool manufacturing through direct control of equipment design aspects and layout structures.

6. Fast Response Time for Better Productivity

High-speed production environments require rapid time responses because time directly impacts operational financial costs. Servo motors receive control signals, which trigger them to modify pump output speed rapidly.

The fast response capabilities of servo systems contribute to improved operational performance in die-casting applications and servo injection moulding systems. The result? The system delivers higher operational speed along with shorter cycle durations while producing less incomplete manufacturing output.

7. Easier Maintenance and Longer Component Life

Because servo motor systems generate less heat and operate with fewer pressure spikes, component wear is minimized. That means fewer breakdowns and less frequent maintenance.

Also, fewer moving parts in a hydraulic servo control system means there’s less that can go wrong. For manufacturers dealing with high uptime demands, this reliability helps avoid costly downtime.

8. Smarter Control and Data Integration

Modern electro-hydraulic servo drives operate with advanced control systems for compatibility. The integration of sensors, PLCs and monitoring systems becomes easy for smarter operations.

The system provides instant tracking of energy consumption capabilities along with early fault detection and real-time production optimization. Modern manufacturing depends on data-driven operations which require this level of visibility for staying ahead in the market.

Where Can You Use Servo Motor Hydraulic Pumps?

The benefits of hydraulic servo systems apply across a wide range of industries:

|

Industry |

Application Examples |

|

Construction Equipment |

Excavators, loaders, compactors |

|

Steel & Cement Plants |

High-tonnage presses, conveyors |

|

Machine Tool Manufacturing |

CNC machines, press brakes |

|

Plastic & Blow Molding |

Injection molding, extrusion, blow molding |

|

Recycling & Waste Management |

Baling presses, compactors |

Each of these sectors requires power, precision, and control—and servo hydraulics meet all three.

Choose the Right System for Your Needs

Switching to a servo motor hydraulic pump isn’t just a technical upgrade—it’s a smart investment in productivity, efficiency, and reliability. When selecting a hydraulic solution, quality and customization matter. At THM Huade, you’ll find a wide range of products tailored to industrial needs across North America and Canada. You can explore Hydraulic Servo Systems and browse Hydraulic Motors here.

So, are you ready to enhance your equipment with efficient, high-performance hydraulics? Get in touch with THM Huade to explore your options today.

FAQ

What is the function of a servo motor in a hydropower plant?

The operation of guide vanes or turbines in a hydropower plant is achieved through the control function of a servomotor. Precise flow control through the motor results in improved operation efficiency and higher output levels. Through its precise functionality, the servo system enables real-time modification to water flow, which leads to performance enhancement with reduced mechanical component deterioration.

For what purpose is a servo motor used?

Servo motors deliver optimal control of speed, position, and torque because these features are essential for particular applications. Unguided machines and robotic systems, as well as hydraulic pumps and moulding equipment, implement servo motors for their operations. These speed-efficient motors maintain critical importance in automated systems as well as high-performance manufacturing facilities.

Why is a servo motor better than an induction motor?

Servo motors deliver superior control performance while being both efficient and quick in their operational responses when compared with induction motors. Servo motors adapt to load modifications without delay because of their instant response mechanisms that enable accurate positioning needs. Precision-driven operations cannot utilize induction motors because they lack the essential feedback control mechanism.

What are the advantages of servo motors over stepper motors?

The motion from servo motors becomes smooth while they produce high torque strength at elevated speeds alongside automatic feedback systems. Servo motors enable higher energy efficiency and prevent missed step errors which stepper motors cannot achieve. These motors adapt perfectly to industrial automation requirements due to their essential properties of stability and performance.

What is the advantage of using a servo motor in an air conditioning system?

Using a servo motor in air conditioning allows for precise control of dampers, valves, and airflow. This enhances energy efficiency, improves temperature regulation, and reduces system wear. It ensures a faster response to changes in room conditions, offering more consistent comfort and lower energy use.