The hydraulic cylinder is being widely used in many industries, from construction equipment manufacturing to plastic injection molding machines. They turn hydraulic energy into mechanical work, allowing heavy machinery to run efficiently.

Unfortunately, hydraulic cylinders, like any other mechanical equipment, also get wear and tear. Any cranky system can outlast only if common failures and solutions are understood.

Statistical research published by MDPI in 2021 identifies the most common causes of hydraulic cylinder failures. Fluid contamination and oil pollution account for approximately 41.1% of these failures. Improper maintenance contributes to around 12.6%, while outsourced components and physical damage to the cylinder are responsible for 10% and 6.5%, respectively. High oil viscosity and incorrect filter selection lead to 5.2% and 1.7% of failures, respectively. Excessive vibrations are also a factor, causing about 1.7% of failures. Notably, around 9% of failure causes remain unidentified.

Let’s look into these issues in more detail.

Hydraulic Cylinder Repair: Common Issues and Solutions

Leakage

Leakage is the most widely observed hydraulic cylinder failure. Seals, cylinder joints, or welds can be potential leak points. Leakage is often caused by:

- Worn-out seals

- Improper installation

- Impurities in the hydraulic oil

- Excessive pressure

How to Fix It:

Of course, the only way to repair a leaking hydraulic cylinder is to assess exactly where the leak is present. Look for any visible cracks or damage to the seals, piston rods, and cylinder body. If the original seals have failed, worn seals can often be cured with better-quality replacement seals. If contamination in the fluid is to blame, a proper flush of the system and replacement of the fluid will be required.

Cylinder Drift

Hydraulic cylinder drift occurs when the small hydraulic cylinder moves without an exterior force acting on it. This issue is usually related to internal leakage in the cylinder. It leads to uncontrolled movements that are potentially risky for equipment workers.

Causes:

- Worn or damaged piston seals

- Wear on components inside the cylinder

- Low hydraulic fluid levels

How to Fix It:

Inspect for piston wear. In many cases, simply replacing the failed seals will resolve the issue. Also, inspect to make sure the hydraulic fluid levels are proper. When there is internal wear, hydraulic cylinder repair restores worn parts (including the piston or cylinder barrel).

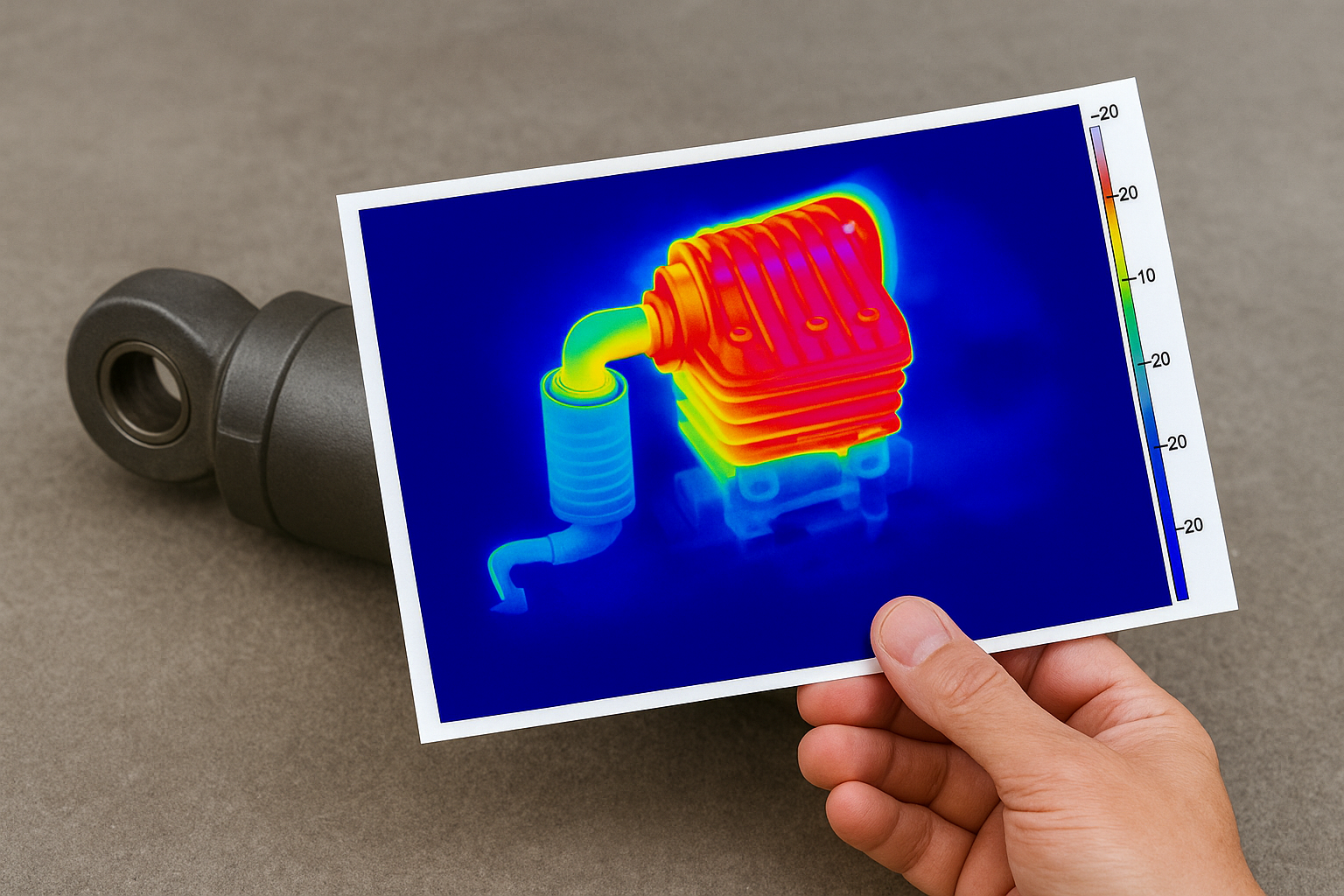

Overheating

Hydraulic cylinders tend to suffer from another common problem: overheating, which is more common in larger equipment. Heat can cause system components to fail sooner than they should, especially when the hydraulic fluid temperature exceeds the optimum range.

Common reasons for overheating are:

- Poor cooling systems

- Overloaded cylinders

- Low-quality hydraulic fluid

- Lack of cylinder maintenance

How to Fix It:

If you are experiencing overheating issues, check the cooling system first. Make sure the oil cooler is working, and check the cooling lines for blockage. The quality of the hydraulic fluid should also be checked, as the mechanical base oils of hydraulic fluids may break down and require replacement to prevent the decomposition of hydraulic fluid additives. Staying in the suggested load range will avoid heating up the cylinder and will increase its life.

Rod Damage

Once the piston rod is damaged, the cylinder will not work. The damage to the rod usually happens because of:

- External impacts

- Contamination

- Lack of lubrication

How to Fix It:

Check the shaft for scratches, gouges, or bends. Damaged rods can damage seals and other parts. Sometimes, the skin on the rod can be reground (if you really need to knock off minor imperfections). In case of extreme damage, a replacement rod should be used to get the cylinder back to working order.

Improper Cylinder Alignment

Incorrect installation can cause disproportionate wear on the seals and other components of the hydraulic cylinder. The misalignment usually happens when the bearing is installed incorrectly or if it has to carry a longer-than-normal load.

How to Fix It:

Align the cylinder using instruments. In case of misalignment, first try to adjust the mounting brackets. If they are too worn out, replace them. Alignment is crucial for all cylinders, as it will keep the cylinder working as it should while also preventing premature wear to seals or other internal components.

Contamination

One of the major causes of hydraulic cylinder failure before time is the contamination of the hydraulic fluid. Over time, foreign particles like dirt, dust, and metal debris can infiltrate the hydraulic system and cause undue wear on all cylinder components.

How to Fix It:

Regularly change the hydraulic filters and inspect the system for leaks that allow contaminants to enter. Using high-quality hydraulic fluids that have good regulations against contamination and keeping a clean working environment will also lessen this risk. Regular maintenance of the cylinder, such as flushing the system to eliminate contamination

Excessive Pressure

If there is undue pressure inside the hydraulic system, it can shorten the lifespan of the cylinder’s seals, valves, and other parts. Hydraulic cylinders are made to handle pressure to specific limits. If you cross these limits, the cylinder will rupture.

How to Fix It:

Calibrate the hydraulic system to avoid exerting too much stress. Use safety valves to prevent pressure from rising beyond a limit. If your unit consistently works in high-pressure situations, purchase a small hydraulic cylinder with a better pressure rating.

Conclusion

Being proactive and diligent about cylinder maintenance, repair, and care can help you avoid critical malfunctions and extend the life cycle of your equipment. From leakage to cylinder drift and rod damage, being equipped to deal with these issues will keep your hydraulic systems well-maintained and your machinery functioning properly and efficiently.

If you’re looking to replace your hydraulic cylinder, check out THM Haude for a reliable option.

FAQs

2. Do smaller hydraulic cylinders fail in the same way as bigger cylinders?

All hydraulic cylinders have common issues, including leaks, contamination, and rod damage. Tiny hydraulic cylinders require normal examination and preservation to remain in proper performing condition.

3. How can I tell when my hydraulic cylinder is due for repair or replacement?

Leakage, drifting of the cylinder, overheating, or odd noises during operation are some signs that your hydraulic cylinder might need repair. If you suspect any of the issues above, it would be wise to inspect the cylinder.

4. How can contamination in the hydraulic system be avoided?

When it comes to avoiding contamination in your hydraulic system:

- Change out the hydraulic fluids regularly, and replace the Filters

- Ensure the seals are not cracked

- Stay in clean places and keep the system away from dirt and dust

- Flush the hydraulics periodically to eliminate contaminants