The proportional valves are crucial in the contemporary hydraulic and pneumatic systems. Such valves are accurate in controlling flow, pressure, and direction, but they are more efficient and controllable. When you want to purchase proportional valve solutions in industrial machines or mobile hydraulics, it is important that you know their proportional valves types and the differences between them.

what are the main types, working principles and how to select the best proportional hydraulic control valve to your application?

Proportional Valve Working Principle

- The valve works through the input of electrical current, typically relayed by a controller.

- The current passes through a solenoid coil that displaces the valve spool.

- The spool moves proportional to the flow or pressure according to the need of the system.

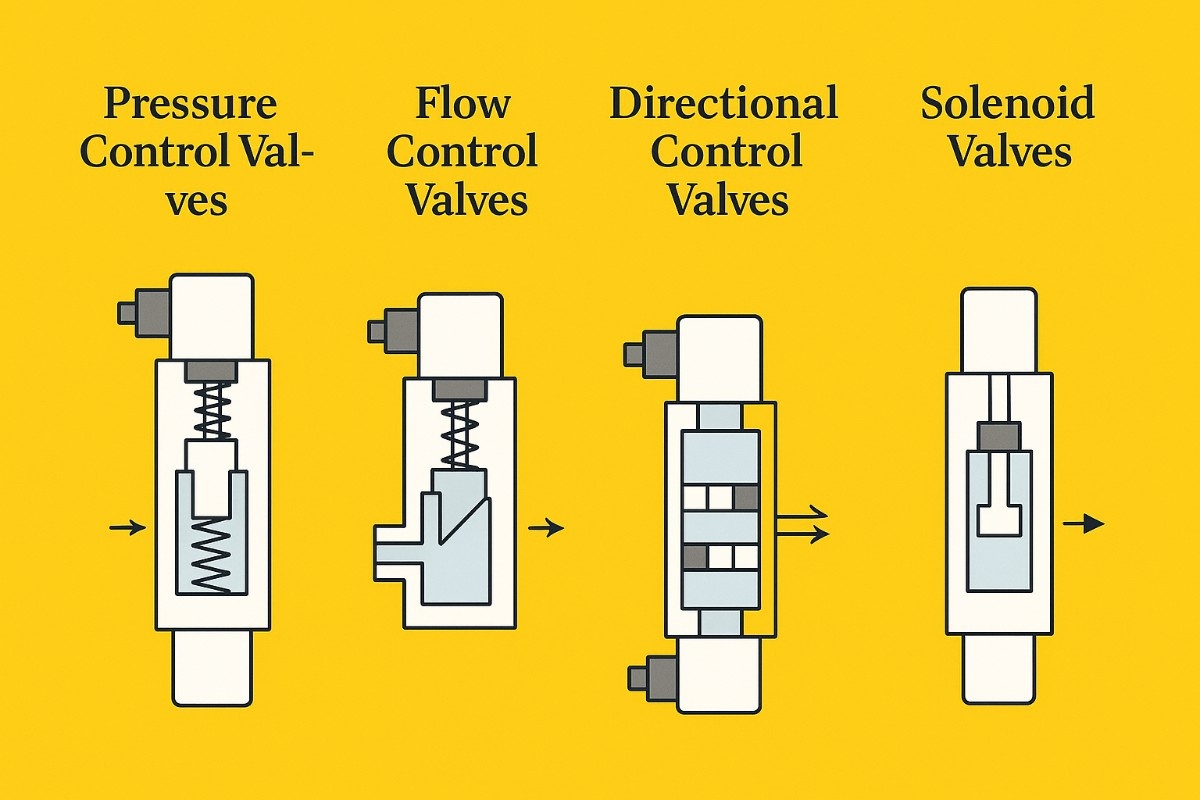

Main Proportional Valve Types

So, we shall divide the most typical types of proportion valves in the hydraulic and pneumatic systems:

1. Proportional Pressure Control Valves

- Applied in controlling pressure according to input signal

- Typical of closed-loop control systems

- Provides stability and overload protection of the system

Popular for:

- Injection molding

- Machine tools

- Mobile equipment

2. Proportional Flow Control Valves

- Regulates the speed of fluid flow on input voltage/current

- Excellent to control the speed accurately in actuators or motors

- Industry terms refer to it as proportional flow control valve

Best for:

- Conveyor systems

- Robotics

- Speed-sensitive operations

3. Proportional Directional Control Valves

- Regulates the flow of fluids as well as modifying flow and pressure

- Provides integrated control in a single unit

- They are referred to as proportional hydraulic control valve

Application areas:

- Mobile hydraulics

- Industrial automation

- Agricultural machinery

4. Proportional Solenoid Valves

- Applies a solenoid to proportional flow or pressure control

- Small and compact design

- Supplied in open-loop and closed-loop forms

Common in:

- Pneumatic systems

- Medical devices

- Compact automation

Proportional Valve in India: Market Trends

The need of proportional valve in India has increased at a very fast rate because:

- Automation in the production industry

- Process control accuracy

- Hydraulic and pneumatic applications Growth

When you are intending to purchase proportional valve, the market in India provides you with the global quality brands at reasonable prices.

Guidelines to Choosing the Correct Proportional Valve

The selection of the types of proportional valves is based on:

- Application requirement: Directional, pressure or flow control?

- Kind of system: Hydraulic or pneumatic?

- Signal compatibility: Voltage, current or digital?

- Environmental conditions: Temperature, dust, humidity conditions.

- Response time: Real-time essential Response time: Real-time essential

- Brand reputation: When you purchase proportional valve, look at reliable options.

Benefits of Proportional Valve Use

- Higher energy efficiency

- Corrective control and feedback

- Fewer wears and tears

- Compact designs

- Smooth operation

Proportional Valve Uses

The proportional valves are applied in different industries:

- Construction machinery

- Manufacturing automation

- Agricultural equipment

- Hydraulic presses

- CNC machinery

Conclusion: Why Should the Right Proportional Valve be Selected?

The knowledge of the various types of proportional valves is crucial towards ensuring that you get the best out of your system. Be it a proportional flow control valve, proportional solenoid valve, or hydraulic proportional valve, all these types have certain advantages depending on the kind of application.

When you are ready to buy proportional valve, trust leading names like THM Huade that combine quality, reliability, and cost effectiveness in their hydraulic solutions.

FAQ’s

Q: Can a solenoid be proportional?

Yes, a proportional solenoid can modulate its output force or position with the input current and so provide a smooth and precise control of hydraulic systems.

Q: What is the difference between directional valve and proportional valve?

A directional valve is used to regulate the flow path of hydraulic fluid (on/off) whereas a proportional valve is used to regulate the direction and rate of flow and the output is variable.

Q: What are the different types of proportional valves?

The major types are proportional pressure control valves, proportional flow control valves and proportional directional control valves.

Q: How to identify valve size?

Valve size is determined by checking the pipe diameter, flow requirements and markings on the valve body or specification sheet.

Q: How do you identify a proportional valve?

A proportional valve usually has a solenoid coil and electrical connectors, so that it can be controlled variable from an input signal.

Q: What are the three most common control valve flow characteristics?

Three primary flow characteristics are linear, equal percentage and quick opening, which influence the change of flow with valve position.