Hydraulic pumps are an important part of any hydraulic system. These pumps drive operations that demand force, precision, and control in different industries, such as construction, automotive maintenance, industrial manufacturing, and so on. Whether in mobile or stationary applications, understanding the difference between electric vs. manual hydraulic pumps is essential for choosing the right solution.

Electrical and manual hydraulic pumps are the two options that businesses and technicians choose from. The comparison between a manual and an electrical hydraulic pump depends on several factors, such as operational efficiency, cost, and ease of use. Furthermore, if you are someone who prioritizes more power & mobility or is searching for reliable mobile hydraulic solutions, it is crucial to understand the pros and cons of each so that you can make the right choice for your specific needs.

In this blog, we will explore the differences between these two types of hydraulic pumps and a few tips for choosing the right hydraulic pump. So let’s get started.

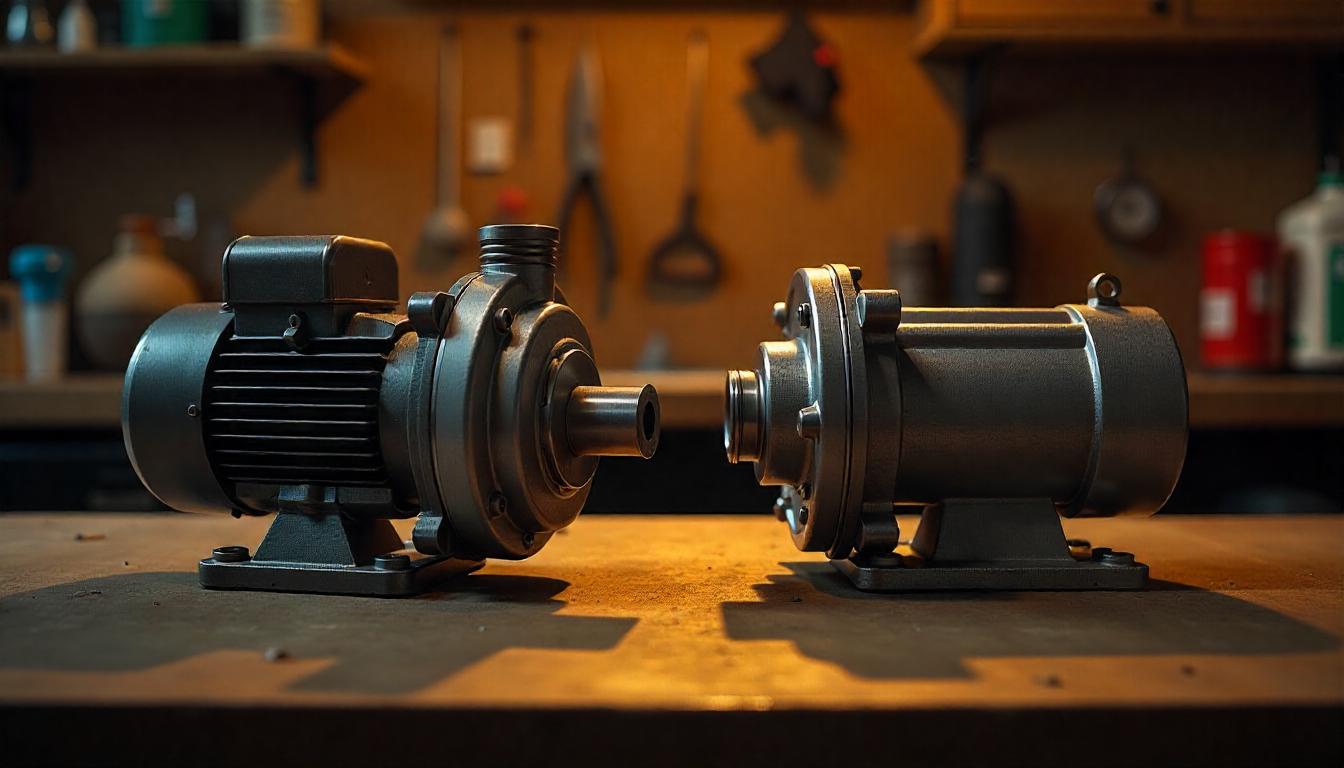

What Is A Hydraulic Pump?

A hydraulic pump converts mechanical energy into hydraulic energy by moving fluid through a system. This fluid is used for heavy-duty tasks, such as lifting, pressing, and powering industrial machines. Hydraulic pumps play a major role in industries such as construction, agriculture, automotive, manufacturing, and so on. They play an important role in mobile hydraulic solutions where performance and portability are crucial. The two most common types of pumps used in the systems are manual, hydraulic pumps, and electrical hydraulic pumps. Each of them offers several advantages depending on their application and environment.

Electric Hydraulic Pumps: Features And Benefits

The operation of the electron hydraulic pump depends on an electric motor, which generates pressure automatically. These pumps are designed for precision and power, making them the best for applications that require consistent and repetitive motion.

Here are some of the key benefits of electric hydraulic pumps:

- These types of hydraulic pumps deliver faster cycle times and better pressure output with minimal user intervention.

- These pumps are easy to use and require no manual effort, which reduces operators’ fatigue.

- Another major benefit of electric hydraulic pumps is their remote operation. They are suitable for environments where accessibility is limited.

- They are very compatible with automated systems or complex machinery setups.

The above-mentioned features make electric hydraulic pumps a cornerstone in power & mobility applications. These devices have proved to be the best option where productivity and automation are prioritized in the system. These pumps support a wide range of mobile hydraulic solutions, such as lifting equipment, construction, and powering tools in manufacturing.

Manual Hydraulic Pumps: Features And Benefits

In comparison to electric hydraulic pumps, manual hydraulic pumps are operated by human power. These types of hydraulic pumps require more physical input, usually by labor or a hand crank. Moreover, they require more physical work and are preferred widely due to their simplicity and reliability.

Here are some of the key benefits of manual hydraulic pumps:

- These types of pumps are lightweight, easy to transport, and perfect for on-site or emergency uses.

- These hydraulic pumps are cost-effective options as they have lower upfront and maintenance costs.

- Manual hydraulic pumps have fewer electronic components, which means less risk of breakdown in difficult conditions.

- Manual hydraulic pumps are used for operations needing slow and controlled movements.

Manual hydraulic pumps are widely chosen in smaller jobs or as a backup for mobile hydraulic solutions, especially where power sources are not available.

Key Differences: Electric Vs Manual Pumps

The major difference between electric and manual hydraulic pumps is based on power, efficiency, and their applications.

| Features | Electric Hydraulic Pump | Manual Hydraulic Pump |

| Power Source | Electric Motor | Human Effort |

| Efficiency | High Continuous Operation | Moderate-Operator Dependent |

| Easy To Use | Minimal Manual Labour | Requires Physical Effort |

| Portability | Bulkier, Required Power | Lightweight, More Mobile |

| Application | High Frequency, Automated Task | Low Frequency Or Remote Work |

| Power And Mobility | Ideal For Modern, Mobile System | Good For Basic Or Back Abuse |

Choosing the right option depends on your specific needs for your application. If you’re looking for efficiency and automation, then electric hydraulic pumps are the best option for you. However, if you are looking for a flexible, low-frequency task in the field, then a manual hydraulic pump offers the best performance and ease of use.

How To Choose The Right Hydraulic Pump?

Choosing the suitable one between an electric and manual hydraulic pump requires assessing several factors, such as:

- Will the hydraulic pump be used continuously or for occasional operations?

- Is power access reliable, or are you operating in remote areas?

- Do you have a budget to invest in expensive solutions for long-term efficiency?

- Do you need to move the pump frequently between locations?

Electric hydraulic pumps offer the best balance between performance and automation for most modern operations, such as industrial and construction environments. However, manual pumps are more successful in specialized and remote areas.

Conclusion

It is crucial to understand the difference between electric and manual hydraulic pumps, and it is essential for optimizing both performance and cost efficiency. While manual hydraulic pumps offer simplicity and portability, electric hydraulic pumps lead in automation, speed, and overall power, which makes them the best choice for demanding mobile hydraulic solutions.

It is crucial to consider that the device you are choosing should align with your goals of power & mobility. If you’re looking for a reliable, high-performance hydraulic system, you can choose THM Huade. It is one of the trusted names in delivering advanced electric hydraulic pump technology and durable mobile hydraulic solutions that meet modern industry demands.

Frequently Asked Questions

Which type of hydraulic pump offers better power & mobility?

Electric hydraulic pumps provide the best power and mobility, especially for consistent operation in various industrial sectors.

Are electric hydraulic pumps suitable for field use?

Yes, electric hydraulic pumps are suitable for field use, but for remote locations, manual pumps are considered a better option.

When should I choose a manual hydraulic pump?

Manual hydraulic pumps are best for emergency uses and locations without power access.

How do electric hydraulic pumps support mobile hydraulic solutions?

Electric hydraulic pumps deliver high pressure with minimal effort, making them perfect for equipment like lifts, presses, and mobile tools.