gsPlanetary gearbox working is one of the most efficient and reliable systems when it comes to power transmission in machines. These gearboxes are compactly design with high torque and smooth performance in different applications. The working principle of planetary gearbox provides the equal load distribution among gears, which provides durability and long service life. They are known to be versatile and thus are use broadly in industries, automation, and in the automotive industry.

THM Huade offers robust and affordable GFT- planetary gearboxes solutions that are designed to meet various industrial applications to deliver customers with high quality performance that is based on excellent engineering and accuracy.

What is a Planetary Gearbox?

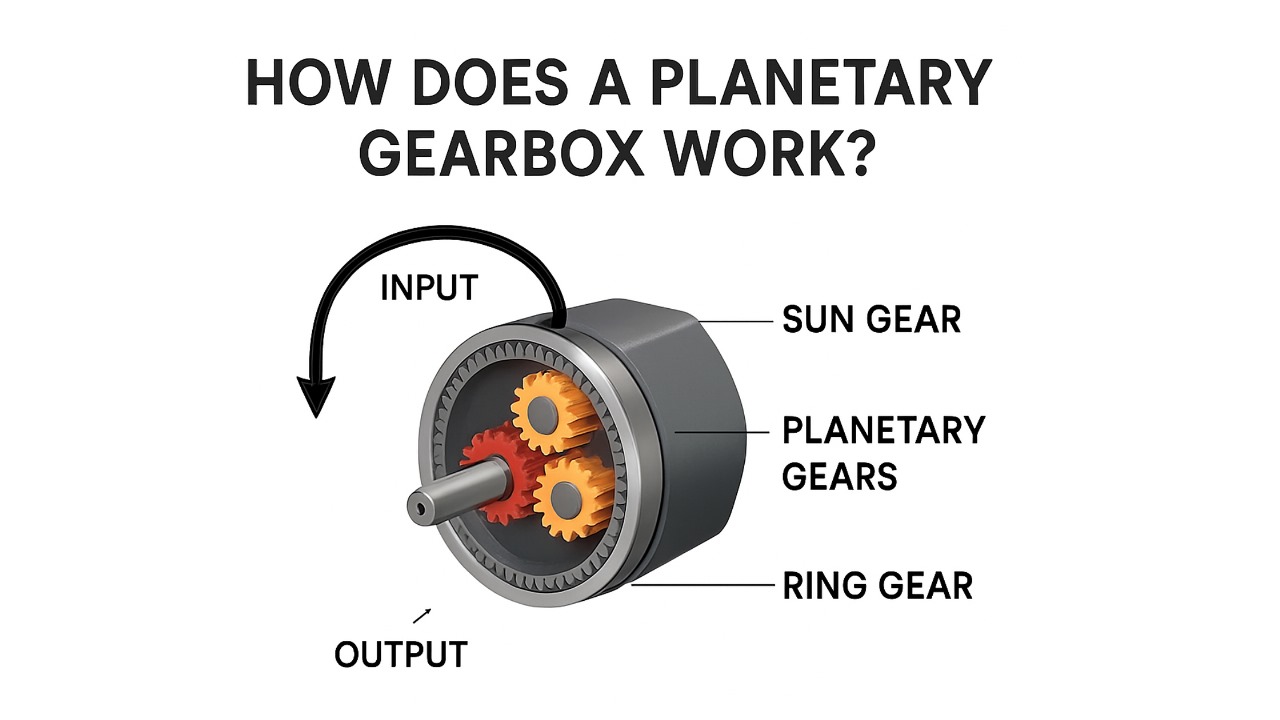

A planetary gearbox is a gear train comprising:

The central gear (Sun gear)

Planet gears (gears that turn around the sun gear)

A gear with teeth on the inside (an outer ring with internal teeth)

Carrier (holds the planet gears in place)

This setup enables the even distribution of torque resulting in smooth operation, small size and large load carrying capacity.

Planetary Gearbox Mechanism – How It Works

The mechanism of planetary gearbox is similar to the way the planets orbit the sun:

- The sun gear is coupled with the input shaft.

- The planet gears spin about the sun gear, and they interact with the internal ring gear.

- The carrier receives the planets and transmits torque to the output shaft.

This system boosts torque and decreases speed, which makes the gearbox very efficient.

The advantages of Planetary Gearbox

The advantages of selecting a planetary gearboxes are various.

High torque density – High performance in a small package

Smooth transmission- There is little vibration and noise.

Durability- Withstands high loads and long operation hours

Flexibility – Can be use with electric, hydraulic and stepper motor gearbox systems

Energy efficiency -Minimizes power wastage in the process of operation

Types of Planetary Gearbox

Planetary gearboxes comes in different varieties which are suited to particular applications:

Single stage – Basic version of moderate torque applications

Multi-stage – Has higher torque and efficiency

Custom -Tailor to specialize equipment

Stepper motor – Suitable to automation and robotics

Applications of Planetary Gearbox

Planetary gearboxes have found extensive application in numerous industries because of efficiency and versatility.

1. Automotive Industry

Applied in automatic transmission to make gear shifting smooth

Delivers high torque in tight areas

Enhances the performance of the vehicle and fuel economy

2. Industrial Uses

Robotics -Ensures accuracy in motion

Packaging machines -Provides uniform motion control

CNC machinery – Precision speed reduction

Construction equipment – Lifts heavy loads easily

Common model codes

TH-GFW5190F,TH-GFT8190F,TH-GFT220,TH-GFT160,TH-GFT110,TH-GFT80,TH-GFT60,TH-GFT50,TH-GFT36,TH-GFT17,GFT 0013 W2 2000/1,GFT 0013 W2 2000/2,GFT 0013 W2 4000/1,GFT 0013 W2 4000/2,GFT 0017 W2 2000,GFT 0017 W2 4000,GFT 0017 W3 2000,GFT 0017 W3 4000,GFT 0024 W3 2000,GFT 0024 W3 4000,GFT 0026 W2 2000/1,GFT 0026 W2 2000/2,GFT 0026 W2 4000/1,GFT 0026 W2 4000/2,GFT 0026 W2 6000/1,GFT 0026 W2 6000/2

Why Choose Manufacturers like THM Hydraulics?

It is necessary to use reputable GFT- planetary gearbox manufacturers when choosing a gearbox. At THM Hydraulics we offer:

Tested planetary gearboxes

Low prices and high durability

Industrial and automotive needs

Customization of various machinery

Conclusion – Understanding GFT Gearbox Made Easy

Knowledge of GFT gearbox working assists industries and engineers to select the appropriate system to transmit power. Planetary gearboxes are very efficient, compact, and have a broad application in the automotive and industrial fields.

At THM Huade, we are specialize in high-quality planetary gearboxes with various applications. You may require solutions in robotics, CNC machines, or automotive industry, and we will assist you.

Enquiry us to know more about our gearbox solutions and the best support you can get to your industrial needs.

FAQs

1. How does a planetary gearbox work?

A planetary gearbox is one that uses a central sun gear, a ring gear, and planet gears to effectively transmit power with a high amount of torque.

2. Why is it called a planetary gearbox?

It is referred to as a planetary gearbox because the gears turn around the centre sun gear just like the planets orbit the sun.

3.What are the main parts of a planetary gearbox?

The major components are the sun gear, planet gears, ring gear, and carrier that cooperate to transmit motion and torque.

4. What are the advantages of using a planetary gearbox?

Merits are small size, high efficiency, long life, smooth running, and the capability of high torque in a small space.

5. Can a planetary gearbox handle high torque applications?

Planetary gearboxes are made to withstand high torque applications, yet are compact and have long service life.