Fluid systems rely on accuracy, stability, and smooth performance. A servo motor hydraulic pump achieves all three with remarkable consistency. Many industries now prefer this technology because it delivers tight control, fast response times, and impressive energy savings.

In this guide, you’ll see how a servo motor hydraulic pump works, why it raises the standards of precision, and how it outperforms traditional hydraulic pumps. You’ll also discover how a servo motor-driven hydraulic pump elevates fluid system reliability from start to finish.

What is a Servo Motor Hydraulic Pump

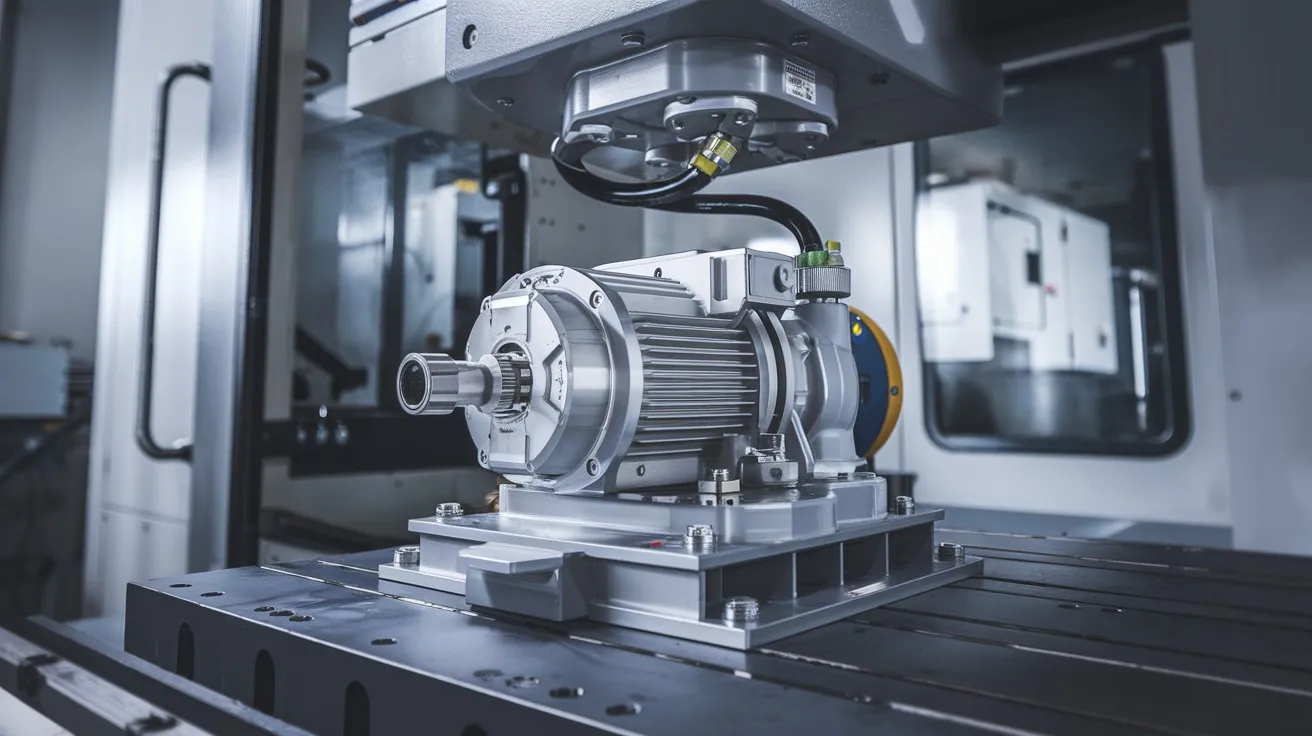

A servo motor hydraulic pump combines a high-efficiency servo motor with a hydraulic pump to control flow and pressure. This pairing creates a smart, adaptable system. Unlike conventional pumps that run at fixed speeds, servo systems adjust instantly. This real-time response boosts accuracy.

Additionally, this design allows operators to fine-tune pressure and flow. As a result, the system maintains smooth operation, even during demanding tasks.

Why a Servo Motor Hydraulic Pump Ensures Exceptional Precision

Precision is a key advantage of servo-based hydraulics. A servo motor reacts in milliseconds, which supports constant accuracy. However, the technology goes further. It creates a consistent flow, reduces heat generation, and lowers the risk of pressure spikes. These benefits are essential for applications such as molding, robotics, aerospace, and CNC machinery.

Therefore, a servo-motor hydraulic pump is ideal when a system cannot tolerate errors or inconsistencies.

How a Servo Motor-Driven Hydraulic Pump Improves System Response

A servo motor-driven hydraulic pump continuously monitors system needs. It adjusts rotational speed based on demand. This reduces energy waste. It also stabilizes the system during load variations.

For example, when the system needs more pressure, the servo motor accelerates smoothly. When the demand drops, it slows down immediately. This dynamic control allows the equipment to operate with exceptional finesse.

In contrast, traditional pumps stay at full speed. They consume unnecessary energy and create needless pressure. The servo approach eliminates these inefficiencies.

What is the Role of a Servo Drive Hydraulic Pump in Fluid Stability

A servo drive hydraulic pump incorporates advanced drive technology. This drive reads feedback signals and corrects variations instantly. Because of this, the system maintains fluid motion stability and predictability.

Additionally, the drive reduces noise and vibration. This is valuable in high-end industrial settings where consistency and comfort matter. As a result, machines equipped with servo drive hydraulic pump technology run smoother and quieter.

Moreover, better fluid stability also increases equipment lifespan. When components experience fewer shocks and less friction, they last longer and require less maintenance.

Servo Motor Hydraulic Pumps vs Traditional Pumps

Traditional hydraulic pumps operate on a constant-speed mechanism. As a result, they waste energy when the system does not require full power. They also generate more heat, which eventually wears out components.

However, a servo motor hydraulic pump operates only when needed. Therefore, it reduces energy consumption by up to 60–80% in many cases. It also lowers heat, minimizes wear, and improves accuracy.

Servo motor-driven systems support rapid pressure changes without sacrificing smoothness. Traditional pumps struggle with this, especially under unpredictable loads.

What are the Key Benefits of Servo Motor Hydraulic Pump Technology

1. Higher Precision and Control

The servo motor responds immediately to changes. This creates exact pressure and flow adjustments. As a result, even complex operations become easier to manage.

2. Greater Energy Efficiency

A servo motor hydraulic pump reduces energy use by operating only on demand. This makes it ideal for large manufacturing environments.

3. Low Heat and Noise Output

Servo systems run cooler and quieter because they avoid unnecessary speed. Therefore, they create a more comfortable and stable working environment.

4. Longer Equipment Life

Smooth operation, reduced friction, and smarter pressure management protect components and extend their lifespan.

5. Fast Response Time

Servo technology reacts instantly, ensuring consistent accuracy even during abrupt load changes.

What are the Applications That Rely on Servo Motor Hydraulic Pumps

Many industries use servo motor hydraulic pump technology to maintain superior control. For example:

- Injection and blow molding

- Precision robotics

- Aerospace systems

- CNC machining

- Metal forming

- Packaging automation

These fields depend on reliable, responsive hydraulic systems. A servo motor-driven hydraulic pump ensures stability even during high-speed tasks.

Why Precision Matters in Modern Fluid Systems

Today’s industries demand perfection. Small fluctuations can damage parts, disrupt production, or reduce safety. Because of this, modern fluid systems require pumps that deliver smooth, accurate performance.

A servo motor hydraulic pump meets these expectations. Additionally, it reduces operational costs while improving product quality. It becomes easier to maintain optimal conditions, avoid downtime, and meet strict production standards.

Conclusion

A servo motor hydraulic pump stands out as a premium solution for high-precision fluid control. Its fast response, energy savings, and consistent stability make it essential for advanced industrial systems. When you combine the adaptability of a servo motor-driven hydraulic pump with the efficiency of a servo drive hydraulic pump, you get unmatched performance. Therefore, industries that rely on accuracy continue to adopt this technology for long-term reliability and superior results.

Experience unmatched hydraulic precision with THM Huade. Upgrade your systems with cutting-edge servo motor hydraulic pump technology. Contact THM Huade today to elevate performance, efficiency, and reliability.

FAQs

2. Why is a servo motor-driven hydraulic pump more efficient?

A servo motor-driven hydraulic pump operates only when needed. This on-demand action decreases energy consumption, minimizes heat generation, and reduces component wear, creating a more cost-effective system overall.

3. What makes a servo drive hydraulic pump better for sensitive applications?

A servo drive hydraulic pump processes feedback in real time. This supports fluid stability, reduces vibration, and prevents pressure fluctuations. Therefore, it’s ideal for tasks requiring tight control and smooth performance.

4. Can a servo motor hydraulic pump reduce maintenance needs?

Yes. A servo motor hydraulic pump reduces heat, friction, and unnecessary load cycles. These factors lower wear on internal components, which leads to fewer breakdowns, less downtime, and a longer lifespan for the entire hydraulic system.

5. Where is a servo motor-driven hydraulic pump most commonly used?

A servo motor-driven hydraulic pump is widely used in molding machines, CNC equipment, robotics, and aerospace systems. These industries depend on accurate pressure control, smooth motion, and rapid response, benefits strongly supported by servo-based hydraulic technology.