Hydraulic cylinders work as one of the most important components in modern machinery. These devices will be present everywhere, from construction to cement plants to machine tools. By knowing how a hydraulic cylinder works, you can also ensure the device’s reliable performance with little downtime.

Let’s examine how these mighty instruments work, their major components, and the different types.

Fundamentals of Hydraulic Cylinders

We know that hydraulic power works on Pascal’s Law. According to this law, a change in pressure applied to an enclosed fluid will be conveyed equally. Essentially, a small force at one end creates a large force at the other end.

Pressurized fluid flows into the cylinder, driving the hydraulic cylinder piston. It is basically a hollow cylindrical container with a piston that, when moved, extends or retracts the rod. This generates the movement necessary to raise or transport heavy payloads.

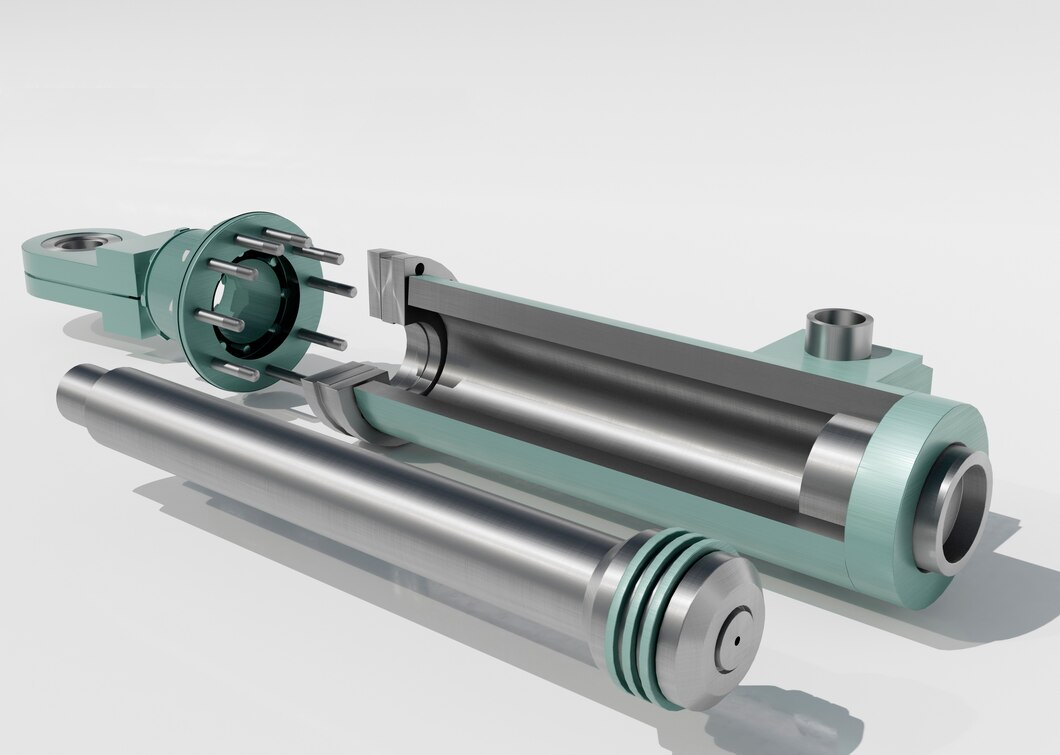

Basic Elements of Hydraulic Cylinder

A hydraulic cylinder, including its various parts, normally consists of several components that work as a unit. Let’s look at each one.

Cylinder Barrel

The main part of a cylinder is the barrel. It retains the pressure and gives the piston a pathway.

Hydraulic Cylinder Piston

A hydraulic cylinder contains a piston that moves back and forth in a barrel. The barrel splits the interior into two compartments, and fluid moves through one of the chambers in the chamber piston.

Piston Rod

This piston rod connects the external load linkage to the piston. As the piston moves, the rod extends or retracts, performing work.

End Caps

Easily, the barrel has end caps attached to both terminal ends. One cap is for the exit of the piston rod. The other seals the back end.

Hydraulic Cylinder Seals

Hydraulic cylinder seals prevent fluid from leaking out and dust and dirt from getting into the cylinder. This maintains the pressure and smooth functionality of the internals.

Ports

The ports are the entrances and exits for the flow to and from the cylinder. They are linked to the hydraulic system.

Types of Hydraulic Cylinders

Tie-Rod Cylinders

In tie-rod cylinders, rods hold the cylinder together. They are also relatively easy to maintain and are mostly employed in industrial machinery.

Welded Body Cylinders

Welded cylinders offer a more compact and robust design. These units do not feature external tie rods, making them the perfect fit for construction and mobile equipment.

Telescopic Cylinders

They are like telescopic cylinders with several stages. They are perfect for applications with limited space and are mainly utilized in dumping and lifting machinery.

Ram Cylinders

Ram cylinders are used for special applications that require high force in one direction. They are commonly found in press stems and heavy lifting.

Key Applications of Hydraulic Cylinders

Hydraulic cylinders are widely utilized across numerous industries due to their strength, versatility, and ability to deliver precise motion control.

Industrial Applications

In industrial settings, hydraulic cylinders are indispensable for tasks that demand accurate force control and repeatable motion. Known for their durability and high performance, they are used extensively in:

- Automated machinery and motion control systems

- Fluid control systems, including valves and actuators

- Construction equipment, such as bulldozers, backhoes, and excavators

- Material handling equipment, including hydraulic lifts, cranes, and conveyor systems

These applications rely on hydraulic cylinders for consistent, high-force output under demanding conditions.

Automotive Applications

In the automotive sector, hydraulic cylinders contribute to both vehicle functionality and user comfort. They are a key component in:

- Vehicle lifting systems, including hydraulic car jacks and workshop hoists

- Convertible roof operations, enabling smooth and controlled opening/closing

- Suspension systems, providing enhanced ride comfort and road stability

- Engine components, where they aid in precision tasks like valve actuation

Hydraulic cylinders enhance both performance and safety in modern automotive engineering.

How a Hydraulic Cylinder Works: The Step-by-Step Process

- The cylinder receives pressurized fluid through the hose from the hydraulic pump.

- The cylinder has two ports, and both are separated by a chamber where the fluid flows through one port.

- The pressure fills and slides the hydraulic cylinder piston in the barrel.

- The rod is pushed (or pulled) by the piston.

- The attached equipment or tool is moved by the rod.

- When fluid pressure is applied to the opposite side of the part, a return stroke occurs.

Importance of Choosing the Right Cylinder

Choosing the wrong type of cylinder can cause system breakdown, leakage, or malfunction. You need to consider these factors before you make the decision.

- Load requirements

- Operating pressure

- Stroke length

- Mounting type

- Environmental conditions

- Look for hydraulic cylinder power

Maintenance Tips to Keep it Running for Years

- Solve for leaks: Do a regular checkup on the hydraulic cylinder seals.

- Clean environment: Dirt can destroy seals and wear components.

- Remember to lube up: Lube your moving parts up for a smooth ride.

- Use high-grade fluid: Bad oil quality will impact hydraulic power and piston movement.

Final Words

I hope you now know everything about hydraulic cylinders. This range of motion is used to move construction equipment or hydraulic cylinder power molding machines é corrected with strength and precision. Knowing its elements and kinds aids you in making more informed decisions regarding your operations.

Always emphasise quality, whether it’s a welded cylinder with heavy duties or a small hydraulic cylinder for compact areas. Focus, in particular, on hydraulic cylinder seals, the piston, and the general design: such decisions impact performance, safety, and longevity.

At THM Haude, we have a range of hydraulic cylinders and other equipment that you can rely on.

FAQs

What are the causes of hydraulic cylinder failure?

Mechanical failure is induced by a seal rupture, dissolved fluid channel, or excessive overload. If these devices are not checked regularly, they eventually fail.

What is the function of the piston of a hydraulic cylinder?

The barrel is the pipe through which the hydraulic cylinder piston moves. The motion generated by this is in response to the fluid pressure.