Ever felt like your machines are not giving their best? Like you’re putting in all the power, but the output just doesn’t flow right? You’re not alone.

One of the biggest reasons why systems don’t work right is poor control over oil or fluid flow. That’s where a hydraulic flow control valve steps in. This small part makes a big change.

In industries across globally, valves that are 1 to 6 inches wide make up more than a third of use. Why? Because they do well with mid-range flow rates. They work smoothly. They don’t break the bank. They keep machines safe.

Let’s learn how this one part can stop leaks, waste, and loss.

What Is a Hydraulic Flow Control Valve and Why Should You Care?

A hydraulic flow control valve does what it says – it controls the flow of oil in your hydraulic system. That means it helps you speed up or slow down the parts that move. Pumps, motors, actuators – they all run better with flow that’s just right.

When flow goes fast, parts may wear out. When flow is slow, the job drags. This valve puts you in charge. That’s why machine makers, steel units, and tool shops rely on it.

There are two types:

- Fixed flow valves – they let the same amount of fluid pass, no matter what.

- Variable flow valves – you can adjust the flow as per your need.

It’s like the tap in your kitchen. A twist of the knob, and the water flow changes.

Now, let’s dig deeper.

Adjusting Hydraulic Flow: How to Use Hydraulic Valve Adjustment Right

You need to know how to tweak flow for best results. Hydraulic valve adjustment is key here.

When you adjust a hydraulic flow control valve, you:

- Avoid oil waste.

- Keep your machine parts cool.

- Extend the life of pumps and motors.

Let’s break it down. You turn a screw or a knob. That changes how wide the valve opens. The wider it is, the more fluid it lets pass. The tighter it is, the less fluid gets through.

Many systems also add pressure-compensated flow valves. These keep flow steady even if pressure jumps or drops. Think of it like cruise control for your machine’s oil flow.

Tips for smart flow control:

- Don’t over-tighten. That can block flow and heat things up.

- Always check pressure along with flow.

- Use the valve’s chart to match flow with pump size.

That’s how smart adjustment gives you more work with less effort.

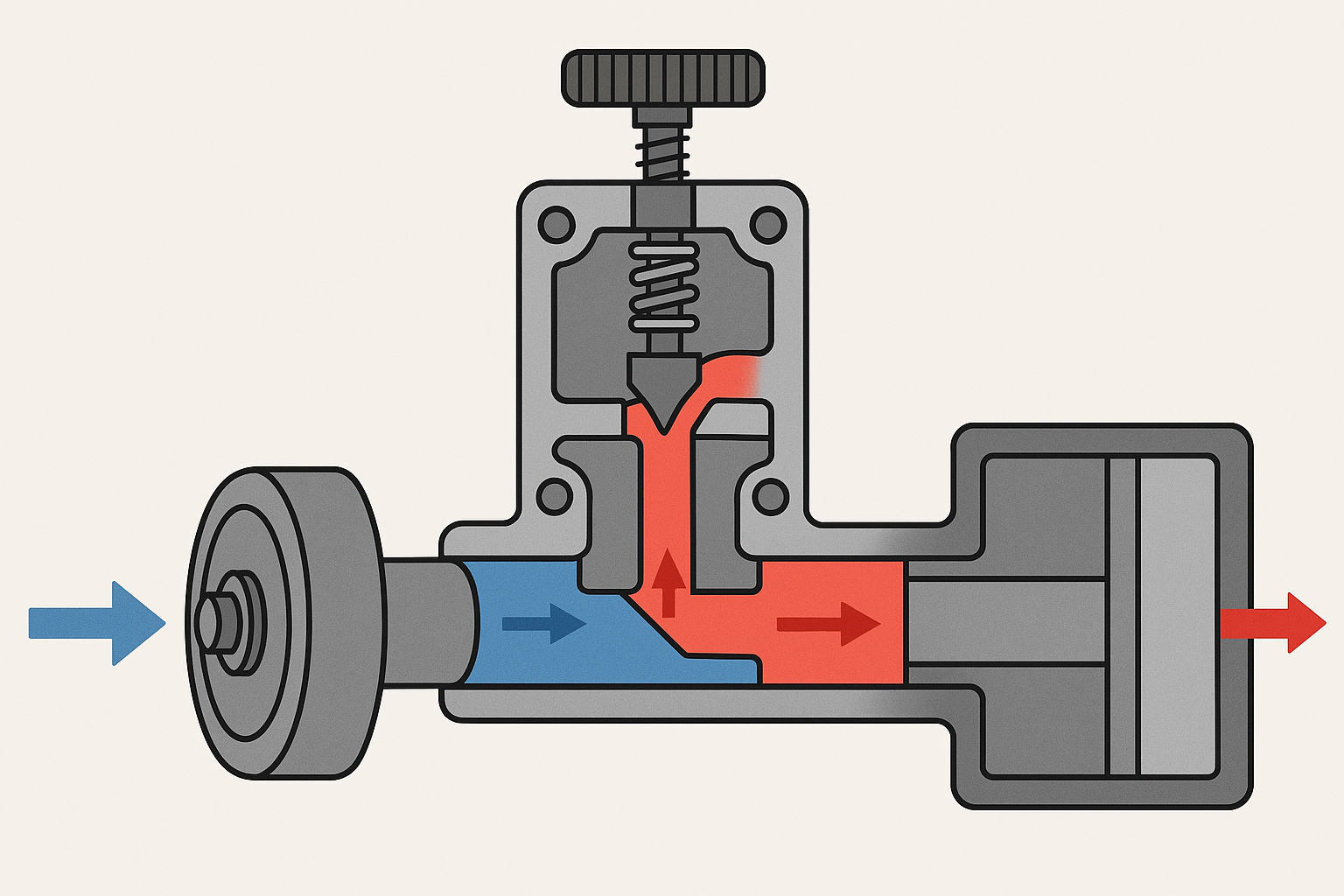

Inside the Machine: How a Hydraulic Flow Valve Works

Here’s where we open it up. What’s inside the valve? How does each part help?

Think of a hydraulic flow valve like a gate in a pipe. It opens and shuts to let oil pass or stop. Each part has a job.

Here’s a clear view:

|

Part |

What It Does |

|

Flow Orifice |

Sets how much oil passes |

|

Needle/Spool |

Moves to open or shut flow path |

|

Spring |

Helps spool go back to start spot |

|

Adjustment Knob |

Lets user set flow speed |

|

Housing/Body |

Holds all parts together |

So when you turn the knob, the needle moves in or out. That changes the gap. Oil flows through that gap. More gaps = more flow. Less gap = less flow.

Some valves come with check valves. That means flow goes one way free, but gets slowed the other way. Perfect for systems that need free return stroke.

This small part, built strong, makes the whole machine flow right.

Choosing and Installing the Right Flow Control Valve Hydraulic

Picking the right flow control valve hydraulic type can save you a lot of time. Pick wrong, and you’ll see leaks, drops, even breakdowns.

Things to look at before you buy:

- Size of the pipe or hose – Don’t fit a small valve in a big line.

- Flow range in liters or gallons per minute (GPM) – Match it with your pump.

- Max system pressure – The valve must bear it.

- Fluid type – Some valves need seals for thick oils.

Install tips:

- Always flush lines before you fix the valve. Dirt kills flow.

- Place it close to the actuator for fast control.

- Check flow direction. Many valves only work one way.

- Tighten as per spec. Not too loose. Not too tight.

You can also add modular valves. These mount on blocks and save space. Steel units and tool plants use them in tight systems.

Wrong pick or poor install? That means poor work and loss. So take your time.

Problems You Can Avoid with the Right Hydraulic Flow Control Valve

A bad valve means big problems.

Common signs of poor flow control:

- Jerky movement of machine arms.

- Slow cycle time.

- Heat build-up in tank.

- Noise or high pitch in pumps.

These point to one thing – flow is not right. Maybe the valve is worn. Maybe it’s too small. Maybe someone did a bad hydraulic valve adjustment.

Fixing these starts with knowing your valve.

Use flow meters to check. You’ll know how much fluid passes per minute. Then match that to your system’s needs.

A good flow control valve:

- Cuts cycle time.

- Cuts energy waste.

- Cuts repair cost.

All with one small part.

Conclusion: You Control the Flow – Now Use It Right

You now know what a hydraulic flow control valve does. And how it can help your machine run smoothly, save power, and last long. Pick the right one. Fix it the right way. And adjust it smartly.

This isn’t just a part. It’s the key to machine life.

THM Huade Hydraulics has deep roots in the field and is known for its strength in flow control valves and all hydraulic needs. Let’s keep your machines strong and steady.

Share this with friends and peers in your field – because smart flow is smart work.

FAQs

Can a hydraulic flow valve work in both directions?

Some can. Some don’t. Valves with check valves let flow pass one way and slow the other. Read the specs before you fix them.

What causes noise in a hydraulic flow control valve?

Air in the lines, wrong valve size, or flow too high. These can all make noise. Use flow meters and filters to stop this.

How do I know if my flow control valve is faulty?

Jerky motion, slow work, or heat near the valve. These are signs. Check for leaks too. Also check if the screw is too loose or too tight.

Do I need a flow control valve on every line?

No. Only on the lines where speed control is key. Some lines need full flow. Others need a slow push. So pick spots wise.