Industries such as steel manufacturing, construction equipment, and plastic injection molding require precision. It’s not a choice, it’s a must. If you work with press machines, CNC press brakes, or molding systems, you understand the importance of accuracy and quick response times. This is where hydraulic servo control systems shine. These systems provide steady, top-notch control by combining the power of hydraulics with the precise control of electronics.

This article explains how servo-controlled hydraulics function and their impact on various industries, including yours. Whether you make heavy-duty machines or plastic molding systems.

What Is a Hydraulic Servo Control System?

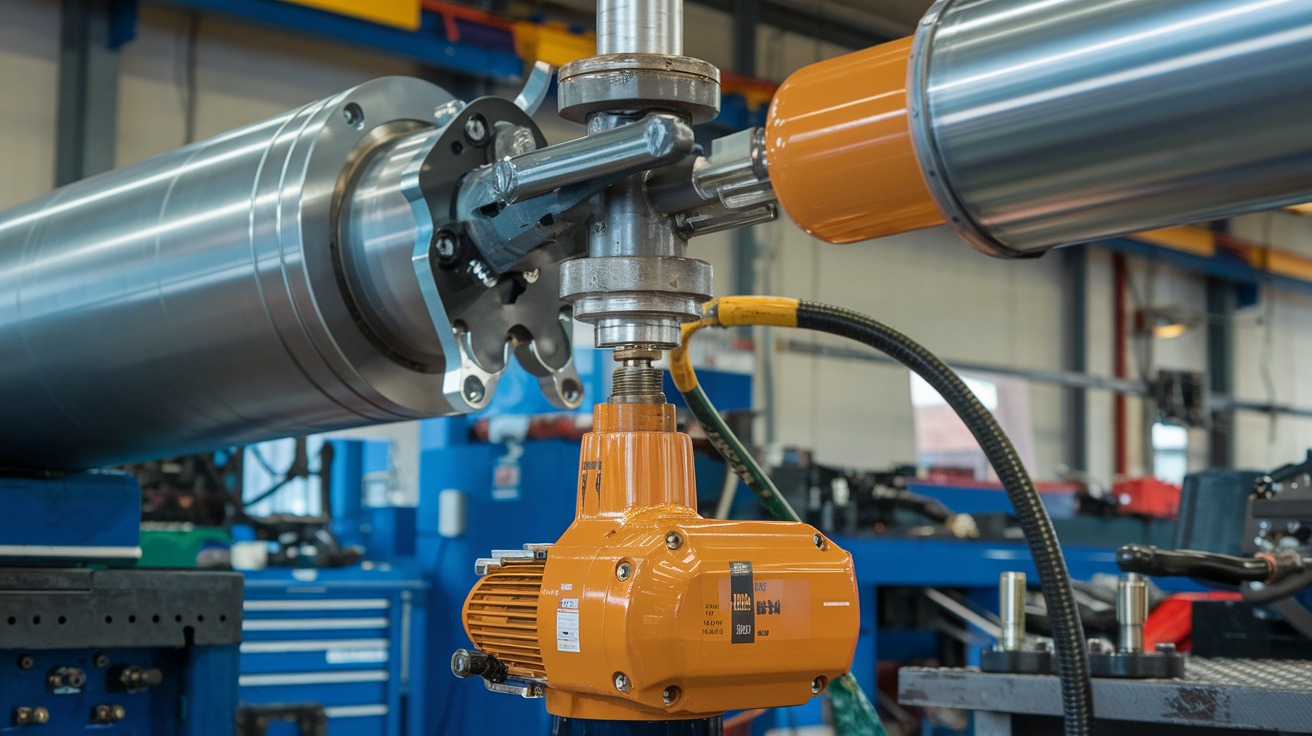

At its heart, a hydraulic servo control system is a closed-loop control mechanism. It features components such as servo valves, hydraulic motors, and a feedback sensor. These work together to control fluid pressure and flow.

Unlike traditional open-loop systems, servo hydraulics monitor output and adjust performance immediately. The system continually compares the desired output with actual performance and makes minor adjustments to maintain precision.

For instance, if you operate a CNC press brake, this feedback loop ensures the press reaches the correct spot every time, even when loads change.

Main Parts of Servo Hydraulic Systems

1. Servo Valves

Servo valves precisely control the flow and direction of hydraulic fluid. You can think of them as the mind of your hydraulic control system. They react to signals from the system’s controller and adjust the flow immediately.

2. Hydraulic Motors

Hydraulic motors turn fluid energy into mechanical movement. In servo systems, motors work in conjunction with sensors and controllers to provide speed and torque as needed.

3. Sensors and Controllers

Sensors monitor position, pressure, or velocity and transmit data back to the controller. The controller then uses this information to instruct the servo valve and motor on how to adjust.

Each part has a significant impact on delivering the high accuracy required for demanding tasks in metal presses, baling systems, and servo injection molding machines.

Where You’ll See Servo Hydraulics at Work

CNC Press Brakes

In the sheet metal world, bending accuracy is key. Servo-controlled hydraulics make sure the press brake’s ram moves with exact force and speed. This results in steady angles and improved repeatability.

Servo Injection Molding

In plastic injection molding, manufacturers must control temperature, pressure, and injection speed to the tiniest detail. Hydraulic servo systems have a significant impact on managing these factors, cutting down on part flaws and production times.

Blow Molding Machines

Like injection molding, blow molding gains from steady consistent pressure control. Servo systems enable smoother transitions and faster production with reduced waste.

Steel Plant Applications

Servo hydraulics boost performance in rolling mills continuous casting machines, and extrusion presses. Better control leads to less material waste and improved safety.

Cement and Construction Equipment

Hydraulic servo systems are now widely used in excavators, concrete pumps, and mixers. They can handle heavy loads while maintaining control of motion, making them highly valuable.

Why Precision Matters

You’re aware of how inaccurate movements can impact things. Parts that don’t quite fit or products that look off can cost you money over time.

Servo hydraulic systems help you:

- Cut down on wasted materials

- Make parts more consistent

- Need less upkeep

- Use less energy

These systems provide immediate feedback and make adjustments on their own. You no longer have to rely on the operator’s skill. The system ensures that every move is purposeful and accurate.

Energy Efficiency and Cost Savings

Traditional hydraulic systems often continue to run even when not in use. This wastes energy and causes more wear on parts.

Servo hydraulic systems work when needed. They use energy just when movement is necessary. Take a servo injection molding machine with a servo pump, for example. It can reduce energy use by up to 70% compared to older setups.

Using less energy doesn’t just mean cheaper power bills. It also allows for smaller cooling systems and lowers environmental impact, a benefit all around.

Linking with Digital Systems

Today’s industrial settings increasingly rely on data. Hydraulic servo systems can link to programmable logic controllers (PLCs) and factory automation networks. This makes it easier to:

- Keep an eye on how machines are running right now

- Plan upkeep based on how much you use them

- Fix problems without stopping work

If your plant is moving towards Industry 4.0, hydraulic servo systems provide the compatibility you need.

Switching Over: Things to Think About

Before you upgrade to a servo-hydraulic system, think about these points:

- Load Needs: Know the top force and speed your job requires.

- Cycle Length: Faster machines need quicker responses.

- How Exact It Must Be: Figure out how tight your limits need to be.

- How It Fits In: Evaluate how well the system integrates with your existing digital tools.

Trusted manufacturers like THM Huade sell servo systems designed for various industrial needs. When you build new equipment or upgrade an existing machine, select a servo system that precisely fits your specific application.

Common Problems and How Servo Systems Fix Them

Parts are not always the same. Immediate feedback gives exact repeated moves. High power bills work when needed, cutting energy used to set up. upSmall designs make machine layout easier. Machines often break down. Using system info to predict when to fix things

Servo-hydraulic systems don’t just fix these issues. They prevent them before they start. This level of control beats what regular systems can do.

Move Towards More Precise Work

If your operations require precision, and they do, it’s time to consider upgrading. Whether you work in metal forming, plastics, or heavy equipment manufacturing hydraulic servo control systems can boost your productivity, enhance product quality, and make your entire system more reliable.

Explore THM Huade’s comprehensive range of hydraulic servo systems to find a solution that meets your specific needs. If you have questions or require custom solutions, please contact us through our contact page.

Precision isn’t just a nice-to-have; it’s a must-have, and now you can achieve it.

FAQs

Do servo-hydraulic systems help cut energy costs?

Yes, they run when needed, which reduces power consumption and cooling requirements.

Can you fit servo systems into older machines?

For sure. Many systems are designed to integrate seamlessly with existing equipment without requiring significant modifications.

How often do you need to service servo-hydraulic systems?

Because of closed-loop control and checks, you don't need to service them as often, and you can better predict when you'll need to.