Hydraulic systems are widely used in various industrial applications, ranging from heavy machinery to small equipment. At the heart of the system lies the hydraulic pump, which is a component that significantly impacts overall performance and energy consumption. Among the various types of pumps available, a hydraulic internal gear pump stands out.

Internal gear pumps are known for their ability to deliver consistent flow, reduce energy and loss, and enhance reliability. As hydraulic systems move towards greater efficiency and cost-effectiveness, it is crucial to understand how hydraulic internal gear pumps contribute to optimizing hydraulic systems.

In this blog, we will discuss the benefits of using an internal gear pump in a hydraulic system and how it improves hydraulic efficiency. So let’s get started.

What Is A Hydraulic Internal Gear Pump?

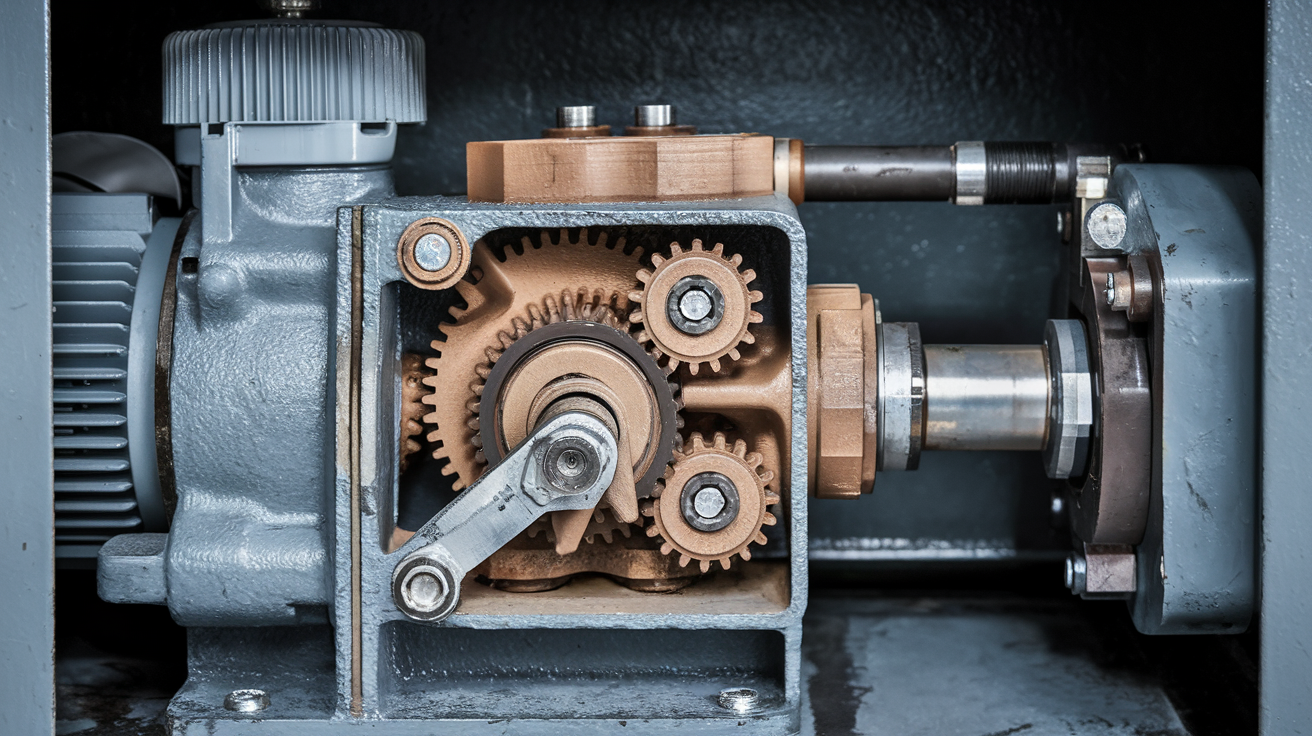

An Internal gear pump is a type of positive displacement pump. They use two gears to move fluid through the pump. One gear is large and has internal teeth, whereas the other one is smaller and has external teeth. These gears combine to create a single space that moves fluidly.

The design of internal gear pumps allows a smooth and continuous flow, which makes them ideal for handling a wide range of fluids, including thin liquids such as solvents and other thick fluids such as heavy oils.

Working Principle Of The Hydraulic Internal Gear Pump

The working principle of an internal gear pump includes a few steps:

Inlet Phase: Gear mesh with the outer rotors when a rotor turns and creates a void that draws fluid into the pump through the pump inlet.

Transfer Phase: The fluid is carried between the inner gear teeth and the outer rotor as they continue to rotate. This expands the volume created by the separation of the gear, pulling the fluid along as the gear teeth engage.

Outlet Phase: The teeth meshing on the discharge side reduce the volume between the gears, forcing the fluid to move out through the outlet. The rotor gear creates a liquid seal with a pump casing, which ensures efficient fluid transfer.

Moreover, in this process, internal gear pumps deliver a smooth flow, which is very beneficial for precise fluid transfer in different industrial applications.

Efficiency Challenges In Hydraulic Systems

In many hydraulic systems, inconsistent fluid flow, excessive energy loss, and unnecessary heat generation are some of the reasons for inefficiency. These challenges, journal reduces performance and increases operational costs over time. Traditional firms usually struggle with internal leakages and high noise levels under pressure, which limits their effectiveness. However, it is crucial to carefully select the pump to boost the overall hydraulic system’s efficiency.

The hydraulic internal gear pump is well-designed to address the challenges of traditional pumps by ensuring stable, smooth, and controlled fluid at different pressure and flow conditions.

How A Hydraulic Internal Gear Pump Addresses These Problems

The hydraulic internal gear pump offers consistent volumetric efficiency and minimal internal leakage. The design of the hydraulic internal gear pump maintains a tight seal, ensuring precise and reduced vibration, which results in a quieter system and better accuracy in motion control.

Additionally, the ability of internal gear pumps to handle both low and high viscosity fluids expands their use in multiple gear pump applications, such as manufacturing machinery and mobile hydraulics. This level of control of the pump improves the system’s responsiveness and exchange component life by reducing wear and thermal stress.

Benefits Of Using Internal Gear Pumps

Using a hydraulic internal gear pump ensures lower energy consumption. The higher efficiency and minimal slippage of the hydraulic internal gear pump reduces the need for excess power to maintain desired pressure and flow, which results in significant cost savings, especially in energy-intensive systems.

Additionally, internal gear pumps ensure smooth operation, which minimizes component fatigue and maintains a consistent temperature, reducing the risk of overheating and fluid breakdown. Across several gear pump applications, including chemical processing, constraint, equipment, food grid systems, and hydraulic internal gear pumps, they deliver long-term value through reduced downtime, maintenance costs, and energy bills.

Applications Where They Excel

The hydraulic internal gear pump is used in different sectors of industry and operational needs.

- In industrial automation, it supports smooth and consistent actuation of cylinders and motors.

- Hydraulic internal gear pumps deliver reliable performance in a demanding environment in the mobile hydraulic sector, such as construction, mining, and agricultural equipment.

- Gear applications in the chemical, pharmaceutical, and food industries benefited from their ability to handle a wide range of fluids with precision and cleanliness.

- The compact size and quiet operation of internal gear pumps make them ideal for application in OEM equipment and Marine systems, where space and noise control are critical.

Conclusion

The demand for high-energy, efficient, and reliable hydraulic systems is increasing day by day. Choosing the right internal gear pump can significantly impact the productivity and cost-effectiveness of your equipment. In comparison to traditional pumps, the hydraulic internal gear pump offers smooth fluid transfer, reduced energy and waste, and exceptional versatility in different ranges of gear pump applications.

If you’re looking to enhance the performance of your hydraulic system, don’t forget to explore THM Huade’s solutions. Get in touch with us today to power a system with smart hydraulic performance.

Frequently Asked Questions

What is the efficiency of a hydraulic gear pump?

The volumetric efficiency usually ranges from 90 to 98%. The gear pump is designed to minimize the internal slippage of fluid and also has high mechanical efficiency.

How does an internal pump work in a hydraulic system?

The internal gear pump creates an expanded volume, which allows liquids to flow into cavities and be trapped by the gear teeth as the gear continues to rotate the casing and partition. The trap fluid is moved from the Intel to discharge around the case.

Do hydraulic machines have 100% efficiency?

In a high-pressure situation, a hydraulic cylinder approaches 100%. And because of its high-pressure application, piston pumps will be essential. The overall efficiency of the axial piston pump in good condition is 92%.

What type of hydraulic pump is most efficient?

Piston pumps are known for being the most efficient and an excellent choice for applications with high pressure and flow rates.