In 2025, the automation and control industry is growing rapidly, and so is the demand for responsive control systems. Hydraulic systems are known for their power and reliability and are continuously evolving to meet the needs of modern consumers. Small servo motors and drives play an important role in the advancement and operation of modern hydraulic systems.

These compact servo solutions are powerful devices that play an integral role in enhancing the efficiency and performance of hydraulic systems. In this blog, we will try to understand how small servo systems enhance hydraulic control and how servo motors work in a hydraulic system. So, let’s get started.

How do small servo systems enhance hydraulic control?

Servo motors play an integral role in enhancing the efficiency of the hydraulic system by contributing to different aspects of operations. One of the major benefits of these speed-control pump drives is improved energy efficiency due to more effective energy monitoring. Further, these motor devices are known for their control, quality, compactness, and lower noise animation.

Servo motors play an important role in enhancing hydraulic systems’ performance by contributing to different aspects of their operations. Let’s examine how a small servo motor enhances hydraulic system performance.

- Servo motors enhance precision and hydraulic control. These devices provide fine control of motion and speed, making the hydraulic system more trustworthy.

- These compact motors upgrade the motion control processes, which reduces energy consumption and improves the overall efficiency of the hydraulic system.

- The motors react and adjust quickly to the changes, and the input enhances the response time, which is crucial in applications where quick and instant movements are required, such as a servo motor hydraulic pump.

What are servo motors?

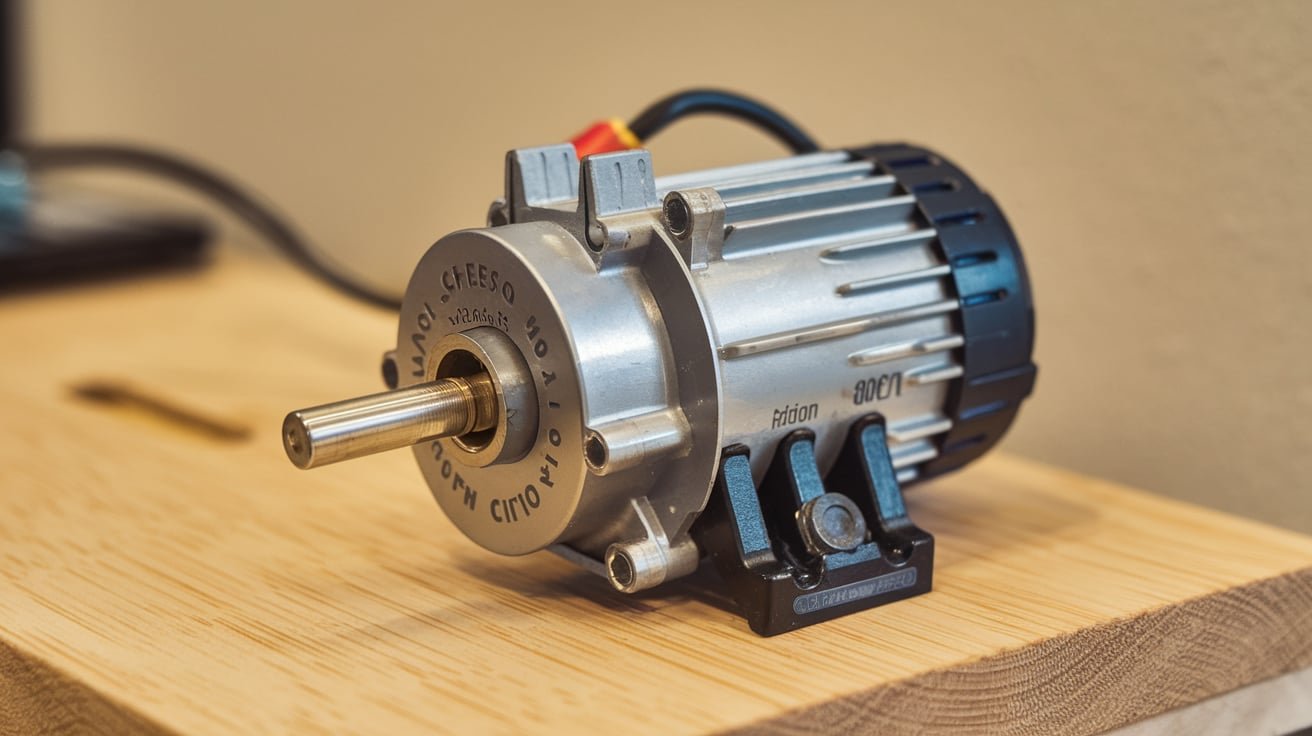

Servo motors, also known as servos, are rotary electronic devices that accurately push parts of the machine. These compact devices are mainly used on the angular axis to control the velocity and acceleration of the system. Their compact and potent design makes them famous among companies, as despite their small size, they generate a good amount of power and are highly energy efficient.

Many manufacturers use servo motors to position control surfaces and rotate objects at accurate angles and distances. They can work in a dynamic environment to ensure the system’s ability and efficiency. Let’s take a look at some of the benefits of using servo motors in a system.

- Servo motors operate at high efficiency, reducing energy consumption and operational costs. Unlike traditional motors, Servo motors are considered a sustainable and cost-efficient option.

- Servo motors generate high power output, making them the best option for applications where high performance is demanded and space is limited. This makes them effective for hydraulic systems and precision assembly machines where heavy and bulky motors cannot be adjusted.

- These compact solutions are known for maintaining consistent torque even at higher speeds. This helps stabilise the power at different speeds. Moreover, this application ensures smoother operation and consistent, better performance.

- One of the major features of servo motors is closed-loop control, which provides precise and accurate system performance. This feature helps the motor’s operation meet the accurate position, speed, and force requirements. In addition, it prevents error accumulation and ensures high accuracy and repeatability in operations.

- Several small servo motor have a high acceleration rate, which helps systems reach high speeds in short intervals and ultimately increases productivity. Servo motors maintain a consistent torque level to ensure the system’s stable and efficient performance.

- Servo motors are popular for their high-performance speed while maintaining precision and efficiency. The motor’s high-speed performance is related to the speed of operation and the level of productivity.

How do compact servo motors work in a hydraulic system?

Servo motors receive a control signal that decides the right position, speed, and torque in a hydraulic system. These compact servo solutions play a major role as feedback sensors. They continuously say that back from the motor control and ensure the desired output by making real-time adjustments. Moreover, they use typical control methods such as PID (proportional, integral, derivative), which ensure the control accuracy of the servo motors.

There are several advantages of using Servo motors in a hydraulic system:

- Decide on extremely accurate positioning.

- Reduces power consumption.

- Enhances system efficiency.

- Quick system response time.

- Reduces mechanical stress

- Extended hydraulic component life.

Challenges and limitations of servo motors in hydraulic systems

There is no doubt that servo motors are popular for their efficiency and better performance. However, certain limitations and challenges make this innovative technology suitable only for specific cases. It is crucial to be aware of the limitations before selecting the right motor:

- Many consider the price of servo motors one of the biggest disadvantages. These types of motors are generally more expensive than simpler systems, such as stepper motors.

- The complicated setup and high maintenance make servo motors less appealing to consumers.

- Another big disadvantage of servomotors is that they are very sensitive to dust, heat, and vibrations. These environmental factors can affect the motor’s performance and durability.

Conclusion

Small Servo motor and drives play an important role in enhancing hydraulic control. Their capability to provide control, efficiency, and overall performance makes them the best option for various industries. With the industry’s evolution, servo motors are ready to enhance the performance and capability of hydraulic systems.