Selecting the right electric hydraulic pump is no longer a straightforward hardware decision. Today’s industrial environments demand quieter operation, stable pressure output, energy-smart performance, and long service life, all without inflating operating costs or maintenance overhead.

Whether you’re powering lifting equipment, automated machinery, mobile systems, or precision tooling, the pump you choose directly shapes productivity, uptime, and long-term cost control. Yet many buyers still rely on generic specifications without understanding how pump design, motor behavior, noise characteristics, and system compatibility interact in real-world conditions.

This guide explains how to evaluate and select an electric hydraulic pump that delivers consistent performance, controlled noise levels, and application-specific reliability without overengineering or overspending.

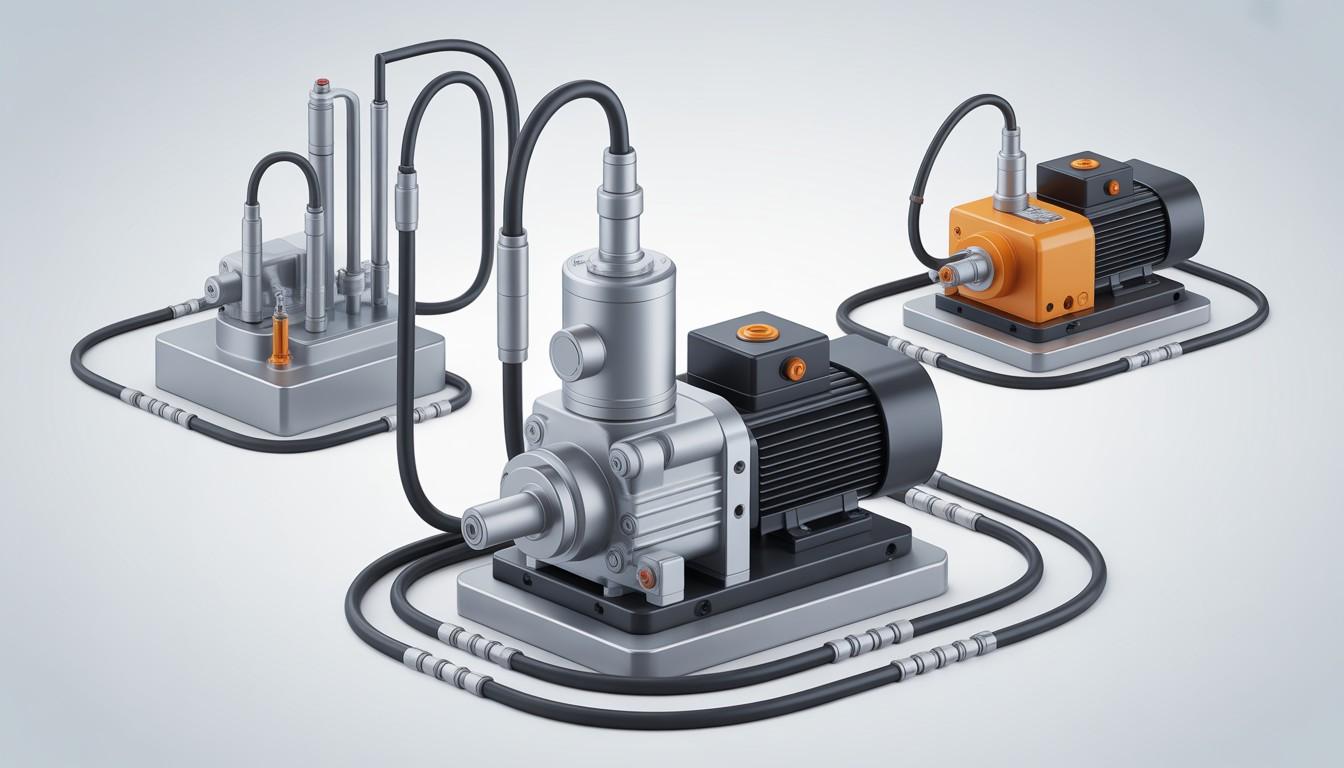

What an Electric Hydraulic Pump Actually Does

At its core, an electric hydraulic pump converts electrical energy into hydraulic pressure, which then powers mechanical motion. Unlike combustion-based systems, electric pump systems offer tighter control, cleaner operation, and predictable output.

However, not all pumps perform the same way under load.

A poorly matched hydraulic power pump can cause pressure fluctuations, overheating, excess vibration, and premature seal failure. Over time, this leads to higher power draw, inconsistent actuator behavior, and increased downtime.

The right pump, by contrast, delivers stable flow, controlled pressure, and predictable response, whether operating continuously on a production line or intermittently in a mobile setup.

Start With the Application, Not the Pump Model

One of the most common mistakes buyers make is selecting a pump based solely on brand reputation or maximum pressure ratings. In practice, the application defines everything.

Before reviewing catalogs or datasheets, clarify the following:

- Will the pump operate continuously or in short cycles?

- Is the system stationary or mobile?

- How sensitive is the environment to sound?

- What pressure range is required during peak load versus idle?

- Will the pump run indoors, outdoors, or in confined spaces?

A portable electric pump used for maintenance tasks has very different requirements than a fixed pump powering automated presses or lifting platforms. Matching the pump architecture to the real operating context is the foundation of a sound decision.

Pump Type Matters More Than Most Buyers Realize

Electric hydraulic pumps come in several core designs, each suited to different pressure and flow requirements.

Gear Pumps

Gear pumps are commonly used in simple systems with steady-flow requirements. They are compact, mechanically straightforward, and cost-controlled. However, they tend to generate more noise and are less forgiving under variable load conditions.

They work best when pressure demands are stable, and system sensitivity is low.

Vane Pumps

Vane pumps deliver smoother flow and lower acoustic output than gear pumps. They are often chosen for applications where sound levels matter, such as indoor machinery or operator-adjacent equipment.

Their ability to maintain stable output under moderate pressure makes them a practical choice for many industrial electric pump systems.

Piston Pumps

Piston pumps are designed for high-pressure, high-precision applications. They provide strong control over flow and pressure but require careful installation and filtration.

When pressure consistency and performance under variable loads are critical, piston-based hydraulic power pumps often justify their higher upfront cost.

Noise Levels Are a Selection Factor, Not a Side Detail

Low-noise operation is no longer a luxury; it’s a requirement in many workplaces.

Excessive pump noise impacts operator comfort, regulatory compliance, and even machine accuracy in precision environments. Noise is influenced by several factors beyond pump type, including motor speed, internal tolerances, mounting method, and fluid quality.

When evaluating pumps:

- Look for measured sound pressure levels, not vague claims.

- Assess vibration isolation options.

- Consider pump speed and motor design.

- Review housing materials and damping features.

A quieter pump often signals better internal balance and tighter engineering, which also contributes to longer component life.

Motor Selection Shapes Performance and Energy Behavior

The electric motor paired with the pump plays a major role in the system’s behavior under load.

Induction motors are widely used due to their durability and predictable operation. Brushless motors, while more expensive, offer finer speed control and lower maintenance requirements in certain setups.

Pay close attention to:

- Motor speed matching with pump displacement

- Power draw under peak and partial load

- Thermal protection features

- Compatibility with variable frequency drives (VFDs)

A well-matched motor prevents pressure spikes, limits excess heat generation, and supports stable pump efficiency across operating conditions.

Flow Rate and Pressure: Balance Beats Oversizing

Many buyers overspecify pumps “just to be safe.” In reality, oversizing introduces its own problems.

An oversized electric hydraulic pump can lead to:

- Excessive power consumption

- Increased heat generation

- Unstable pressure control

- Shortened seal and hose life

Instead of chasing maximum ratings, focus on actual operating ranges. Determine the flow rate required to achieve the desired actuator speed and the pressure needed during peak load events.

Selecting a pump that operates within its optimal range improves efficiency and reduces lifecycle costs.

Pump Efficiency Is About System Behavior, Not Marketing Claims

Pump efficiency is often presented as a single number, but real performance depends on how the pump behaves inside the system.

True efficiency considers:

- Electrical input versus hydraulic output

- Heat losses under continuous operation

- Pressure stability under changing load

- Internal leakage over time

A pump that performs well at rated conditions but degrades quickly in real-world use will cost more over the long term. Ask suppliers for performance curves, not just peak figures.

Portable Electric Pumps: Compact Doesn’t Mean Compromised

Portable electric pump systems are widely used in maintenance, rescue operations, construction, and field service. These pumps must balance size, weight, output, and durability.

Key considerations include:

- Duty cycle limitations

- Cooling mechanisms

- Ease of transport and setup

- Resistance to dust and moisture

- Quick-connect compatibility

A portable electric pump should deliver reliable pressure without overheating or excessive noise, even when operated in uncontrolled environments.

Build Quality and Materials Define Longevity

Pump internals are subjected to constant stress from pressure, heat, and fluid flow. Material selection directly affects wear resistance and service life.

Look for:

- Hardened steel or alloy components

- Precision-machined housings

- High-quality seals compatible with your hydraulic fluid

- Corrosion-resistant finishes for harsh environments

A well-built electric hydraulic pump may cost more initially, but pays back through reduced downtime and fewer replacements.

Maintenance Access Is Often Overlooked, Until It’s Too Late

Ease of maintenance is rarely highlighted during purchasing discussions, yet it strongly affects the total cost of ownership.

Evaluate:

- Accessibility of filters and seals

- Clarity of service documentation

- Availability of spare parts

- Manufacturer support response times

A pump that is difficult to service increases labor costs and extends repair downtime.

System Compatibility Prevents Hidden Failures

An electric pump system does not operate in isolation. It interacts with valves, hoses, actuators, reservoirs, and control electronics.

Before finalizing a pump:

- Confirm compatibility with existing pressure ratings

- Ensure fluid type alignment

- Validate electrical standards and voltage requirements

- Check control integration if automation is involved

System mismatches often lead to erratic performance, which is mistakenly attributed to the pump itself.

Certifications, Testing, and Supplier Transparency

Reputable pump manufacturers provide documented testing results, compliance certifications, and clear operating limits.

Look for:

- Pressure testing data

- Thermal performance validation

- Noise measurement standards

- Quality control certifications

Transparent documentation signals confidence in product performance and reduces risk for buyers.

Cost Evaluation Should Include the Entire Lifecycle

Upfront pricing tells only part of the story.

A lower-priced hydraulic power pump may consume more electricity, require frequent servicing, or fail prematurely. Conversely, a higher-quality pump with stable performance can reduce operating costs year over year.

Consider:

- Energy consumption over time

- Maintenance frequency

- Replacement part availability

- Downtime impact on operations

Lifecycle thinking leads to smarter purchasing decisions.

Conclusion

Choosing the right electric hydraulic pump is a technical and strategic decision. The goal is not simply to meet pressure requirements but to support reliable, quiet, and predictable system behavior over the long term.

By grounding your selection in application requirements, understanding pump architecture, evaluating real-world performance metrics, and prioritizing build quality, you reduce risk and deliver consistent operational value.

A thoughtfully chosen pump doesn’t just move fluid; it supports productivity, safety, and control across every cycle of operation.

FAQ’s

2. How do I choose the right electric hydraulic pump for my specific application?

Start by defining your operating pressure, required flow rate, and duty cycle rather than selecting a pump based on maximum ratings. Consider whether the pump will run continuously or intermittently and whether it will be used in a fixed or portable setup. Noise sensitivity and available power supply should also guide the decision. Matching the pump’s design to actual operating conditions leads to better system performance and a longer service life.

3. Why is noise level an important consideration when selecting an electric pump system?

Noise affects operator comfort, workplace compliance, and overall system stability. High noise levels often indicate vibration, poor internal balance, or improper mounting. Low-noise pumps typically offer smoother flow and reduced mechanical stress. Over time, quieter operation also helps limit wear on connected components.

4. What is the difference between a portable electric pump and a fixed hydraulic power pump?

Portable electric pumps are designed for mobility, compact size, and short-duty operation in field or maintenance tasks. Fixed hydraulic power pumps are built for continuous or high-cycle operation in stationary systems. Portable units prioritize ease of transport and setup, while fixed pumps focus on sustained pressure stability and thermal management. Choosing the wrong type can result in overheating or reduced performance.

5. How do flow rate and pressure impact pump selection?

Flow rate determines how fast hydraulic actuators move, while pressure defines the force they can deliver. Selecting a pump with excessive capacity can lead to energy waste and unstable system behavior. Undersizing, on the other hand, causes slow response and performance limitations. The best approach is to select a pump that consistently operates within the required working range.

6. How can I reduce maintenance issues with an electric hydraulic pump?

Proper sizing, clean hydraulic fluid, and correct filtration significantly reduce wear. Choosing pumps with accessible service points makes routine checks faster and more reliable. Stable operating temperatures and pressure levels also extend the service life of seals and bearings. Regular inspections prevent small issues from becoming system-wide failures.

7. Are electric hydraulic pumps suitable for low-noise indoor environments?

Yes, many modern electric hydraulic pumps are designed specifically for controlled sound output. Vane- and piston-based pumps generally offer smoother, quieter operation than basic gear pumps. Proper mounting, vibration isolation, and motor selection further reduce sound levels. These pumps are widely used in workshops, production floors, and automated facilities.

8. What should I consider when evaluating the total cost of an electric pump system?

The initial purchase price is only one part of the overall cost. Energy consumption, service frequency, spare parts availability, and downtime impact long-term expenses. A pump with stable performance and lower power draw often costs less over its operating life. Evaluating the full lifecycle leads to better purchasing decisions and fewer operational surprises.