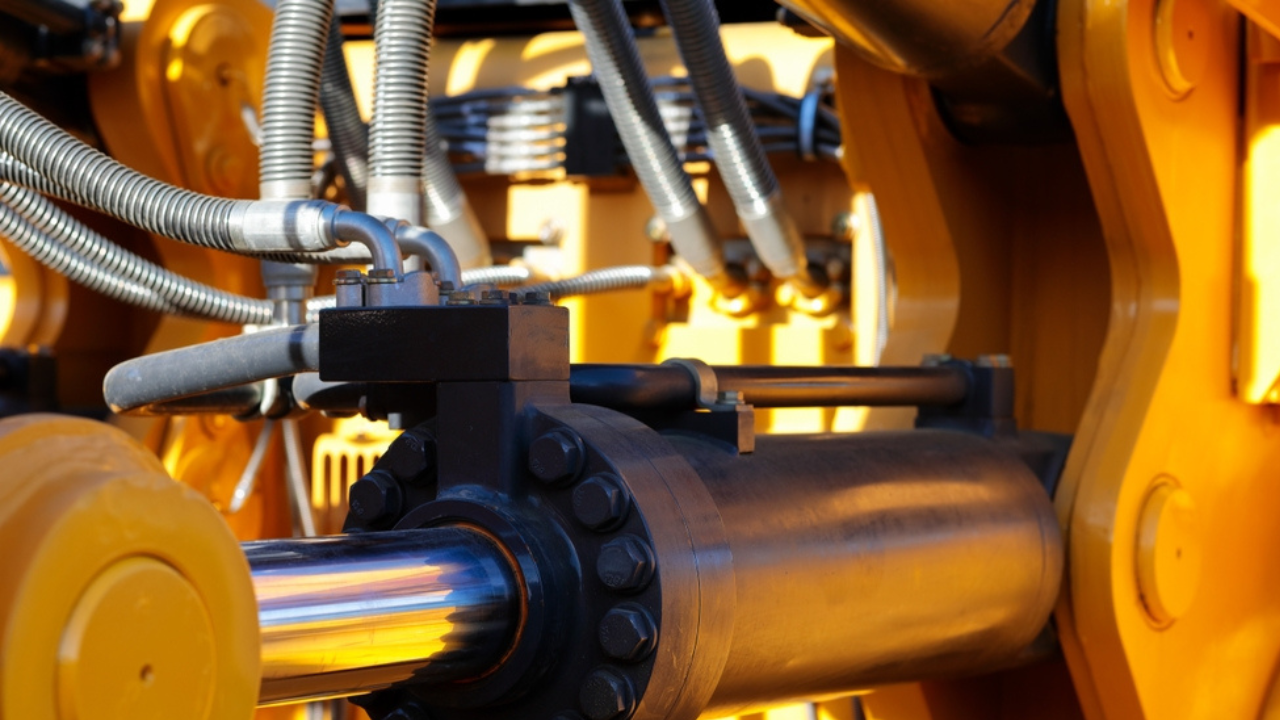

A hydraulic cylinder is essential in most industries, including, but not limited to, manufacturing, agriculture, and construction. From a mini hydraulic cylinder to a custom hydraulic cylinder, performance relies on leak free operation and pressure management. You should check for leaks as well as any leakage pressure to prevent breakdowns and stay safe.

This guide will give step by step guidance in the inspection of small hydraulic cylinders, single acting hydraulic cylinders, and double acting hydraulic cylinders, including the OB/OD type of cylinders, and hence can also be used as a guide to all the type of hydraulic cylinders in India.

Typical Symptoms of Hydraulic Cylinder Leaks

Watch for these warning signs of possible internal or external leaks:

- Unusual noises or hissing sounds

- There are oil leaks around the seals or at the ports

- Slow or inconsistent cylinder movement

- Reduced pressure output

- Fatigue of the cylinder rod

How to Test for Hydraulic Cylinder Leaks

1. Visual Inspection

Start with a physical inspection:

- Check seals, hoses and connections for oil contamination.

- Examine the rod for pockmarks and scoring.

- Inspect the cylinder body and attachments for evidence of cracks.

Now, do this continuously, especially with a high-usage or exposed one like a small hydraulic cylinder.

2. Pressure Holding Test

This test is to determine if your hydraulic cylinder is holding pressure internally

Steps:

- Operate the hydraulic pump to pressurize the cylinder.

- Close off the valve to line the cylinder.

- Look at the pressure gauge when you hear or see it drop.

A gradual loss of air pressure could mean an internal leak – typically around the piston seals.

3. Cylinder Drift Test

Particularly in the case of double acting hydraulic cylinders

How to perform:

- Extend and depressurize the cylinder.

- When the oral instrument collapses on itself marking the rod or measuring the extension.

- Watch to see if the rod retracting slowly.

Piston to bore sealing Ring wear or damage -Drifting: Indicates internal leakage, probably piston to cylinder bore.

4. Hydraulic Flow Meter Test

For more advanced diagnostics:

- For return line flow, use a flow meter.

- Too much return flow means there are leakage paths within the cylinder.

Results can validate mini hydraulic cylinders or custom hydraulic cylinders as well.

5. Ultrasonic Leak Detection

- Listen for internal flow passing from the leak with ultrasonic leak detectors.

- Particularly useful with small or difficult-to-reach cylinders.

Ideal for production lines utilizing small hydraulic cylinders, where down time can be costly.

Tips to Prevent Hydraulic Cylinder Leaks

- Inspect hydraulic cylinder supply lines and filters as necessary.

- When replacing seals during scheduled maintenance.

- Avoid exceeding rated pressure limits.

Choose the appropriate kind: single acting hydraulic cylinder vs. double acting hydraulic cylinder depending on load requirements.

Special Notes on Cylinder Types

1. Single Acting Hydraulic Cylinder

- Applied pressure is unidirectional.

- Short and sweet with a drift issue while in use.

2. Double Acting Hydraulic Cylinder

- Controlled movement in both directions.

- Less hands-off but more control.

Why Leak Testing Is Vital for Hydraulic Cylinders in India

In India Various industries is using hydraulic cylinders very vastly for regular purpose work. Whether you’re buying a mini hydraulic cylinder or a heavy-duty industrial one, a leak can be improved by:

- Equipment lifespan

- Operational safety

- Maintenance costs

- Hydraulic cylinder price efficiency

Conclusion – Trust THM Huade for Leak Free Cylinders

Testing your hydraulic cylinder for leaks and pressure loss on a scheduled or preventive maintenance program helps in providing reliability and safety in whatever system it is installed in. early detection whether it is small hydraulic cylinder or heavy duty custom hydraulic cylinder the damage that arises can cost a lot.

For reliable quality, leak free components and sturdy fabrication, look no further than THM Huade your preferred supplier of hydraulic cylinders in India.

FAQs

Q: How do you detect a leak in a hydraulic cylinder?

Visually inspecting, performing a pressure hold test, using a ultrasonic device to detect internal and external leaks.

Q: Can a hydraulic cylinder lose pressure without leaking?

Yes, there could be damage to an internal seal causing loss of pressure without any external leak.

Q: What is the best method to test small hydraulic cylinders?

Pressure holding testing and ultrasonic leak detection both of which are best for mini hydraulic cylinders, custom hydraulic cylinders etc.

Q: How often should you inspect hydraulic cylinders?

The checks should be performed once a month, or once a week for demanding applications.

Q: How many types of cylinders are in hydraulics?

They are primarily two types of hydraulic cylinders, namely single acting hydraulic cylinders and double actings hydraulic cylinders. These are telescopic, differential, and specialist hydraulic cylinders respectively.

Q: Which metal is used in cylinder blocks?

The blocks are often cast in iron or aluminium alloys. These materials provide strength, heat resistance, and durability.