When it comes to hydraulic systems for mobile equipment, efficiency is the top priority. The engineer’s mobile hydraulic design, whether it’s for construction machinery or agricultural vehicles, directly impacts the performance, fuel consumption, and long-term maintenance costs. With the high demand for compact, powerful, and energy-efficient machinery, it is important to focus on intelligent design and proactive maintenance.

In this article, we will explore practical tips to enhance the efficiency of hydraulic systems for mobile equipment, and will also focus on best practices in mobile hydraulic repair and prevention strategies offered by professional mobile hydraulic services. We are sure that these tips will help you build more reliable and cost-effective mobile hydraulic solutions. So let’s get started.

What Is A Mobile Hydraulic System?

A hydraulic system for mobile equipment refers to all types of hydraulic machines that are mobile and used in different types of environments. Such as:

- Forklift

- Cranes

- Diggers

- Harvesters

- Fire engines

- Telescopic handler

- Wood chippers

- Winches

- Apple Pickers

- Air Seeders

- Mowers

- Trucks

Mainly, any type of machine that is used outdoors in hot, cold, wet, or dry conditions can be defined as part of a hydraulic system for equipment. These mobile hydraulic systems are commonly found in construction, forestry, agriculture, and mining machinery.

The hydraulic machines might be classified as drilling rigs and fall under mobile hydraulic design due to their function and mobility. The proper classification of mobile hydraulic design is essential for effective mobile hydraulic repair and ensuring the right mobile hydraulic services are applied.

Key Design Tips For Efficiency

Designing an efficient hydraulic system for mobile equipment requires a balance between power and energy conservation, as a poorly designed system can lead to overheating and frequent breakdowns that require costly mobile hydraulic repair. Let’s check out some of the essential mobile hydraulic design tips that will help you enhance performance and reliability.

Balanced System Pressure And Flow

One of the most common issues in hydraulic systems for mobile equipment is unbalanced pressure and floor requirements, which lead to waste of energy and increased heat. To avoid this, use load sensing and pressure-compensated systems that can easily fulfill the demand, reduce power loss, and improve overall system efficiency.

Select High-Efficiency Parts

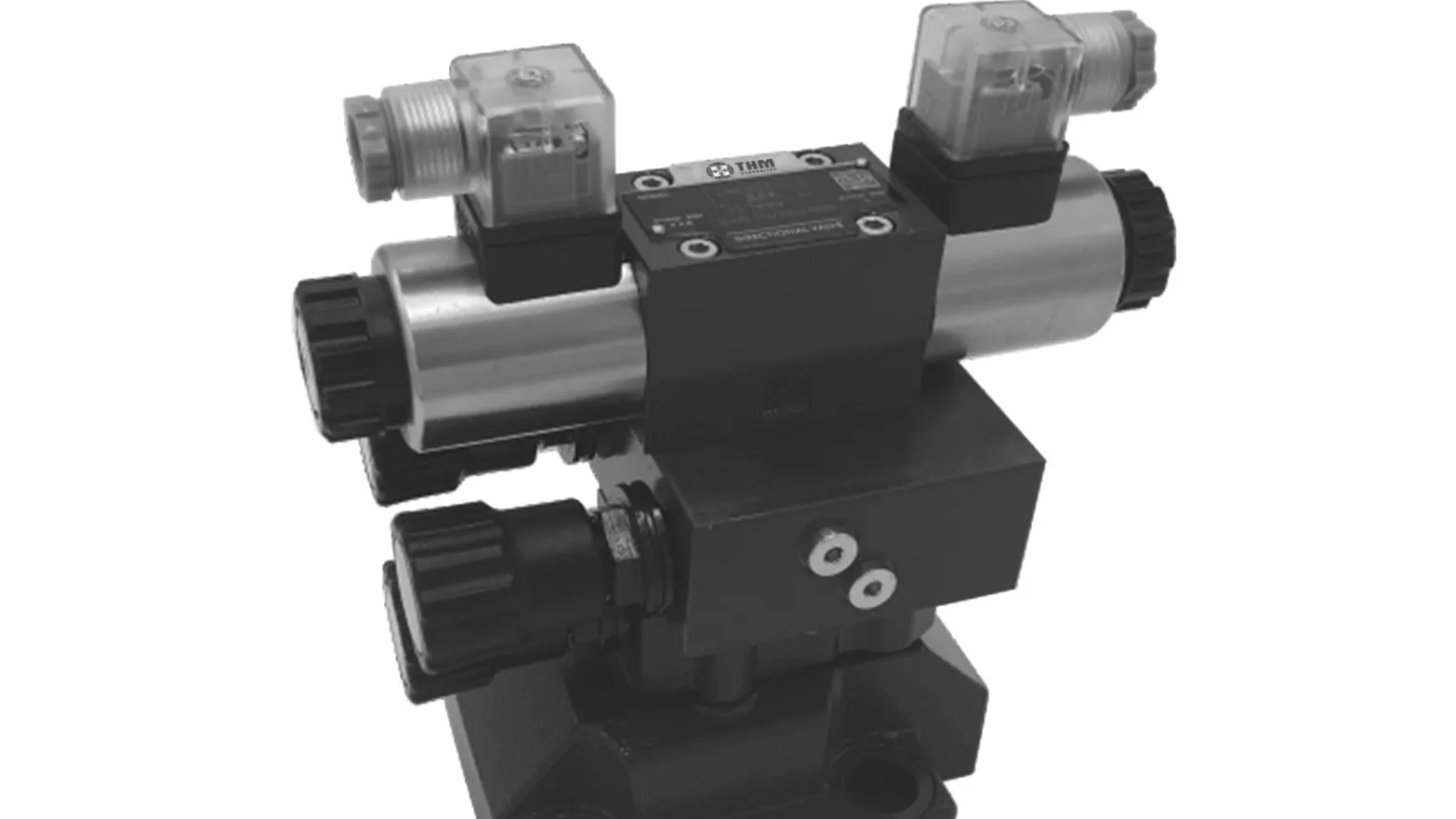

It is crucial to choose pumps, motors, and valves that are specifically designed for mobile hydraulic systems, as they can easily adjust the output based on load conditions, which reduces energy waste. Make sure parts such as hoses, cylinders, and fittings allow optimal flow and pressure. This will minimize the resistance and maintain system integrity.

Size Hydraulic Lines Correctly

Using undersized hydraulic lines can create high-pressure drops, increase system heat, and reduce component life, and using oversized lines can add unnecessary weight and cost. However, using the right hydraulic lines ensures smooth operation and extends the lifespan of hydraulic systems for mobile equipment.

Use Energy Recovery Techniques

Using a regenerative circuit allows the reuse of energy during low-demand cycles. Mobile hydraulic design can store axial energy and release it when needed, reducing strain on the power source.

Use Smart Controls And Automation

Advanced electronics, such as electronic control units, sensors, programmable logic, and controllers, ensure smart operations of the hydraulic system. Moreover, proportional server valves improve control precision, and automated systems reduce errors and optimize efficiency. Many mobile hydraulic services now offer integration of these technologies.

Prioritize Heat Management

Excess heat is one of the top causes of failure of most mobile hydraulic designs. Use heat exchanges, oil, coolers, and thermal bypass valves to keep the temperature of the fluid within safe parameters. Ensure proper ventilation and fluid selection to reduce thermal degradation in hydraulic systems for mobile equipment/

Protection Contamination

Using contaminated hydraulic fluid can lead to premature wear and, most importantly, system failure. Add a high-efficiency filtration system and place filters in a location that is accessible during routine maintenance. Preventive design simplifies future mobile hydraulic repair and reduces long-term service costs.

Challenges With Mobile Hydraulic Design

Mobile hydraulic systems also come with several challenges. Let’s check out some of the common challenges:

Limited Space

One of the biggest challenges with mobile hydraulic design is limited space. Hydraulic systems for mobile equipment must fit within confined design spaces on machines. The designer must ensure that all the components are correctly placed to maintain the functionality within the space constraints. So it is crucial to create creative design solutions with both space and performance requirements.

Weight Limitations

Unlike other stationary industrial assistance, mobile systems have strict weight limitations, as excessive weight can cause hindrances during the move. So it is crucial to select hydraulic components carefully and also consider the total weight of the engine, transmission, and other machine parts.

Environmental Factors

Mobile systems are exposed to weather conditions, such as wind, rain, snow, heat, and humidity, and this can impact system operations and performance. So, in a hydraulic system for mobile equipment, it is crucial to use high-quality, durable components that can easily withstand extreme temperatures and humidity.

Conclusion

Designing an efficient hydraulic system for mobile equipment is more about making smart, informed decisions that reduce energy and waste, improve performance, and extend the lifespan of a machine. By focusing on the main principles of mobile hydraulic design, as mentioned above, you can significantly cut down on operating costs and can easily avoid frequent mobile hydraulic repairs.

If you are looking to upgrade an existing system, integrating these efficiency tips will help you enhance the performance and reliability of the system. If you are also looking for expert guidance or components that you can trust. Get in touch with THM Huade today!

Frequently Asked Questions

How to improve the efficiency of the hydraulic system for mobile equipment?

To improve the efficiency of the mobile hydraulic system. You can optimize the pressure and flow, maintain clear fluid, and integrate smart control systems.

What is the most common challenge in mobile hydraulic systems?

The most common challenges in mobile hydraulic systems are limited space, weight limitation, and environmental factors.

What is the difference between industrial and mobile hydraulic systems?

Industrial hydraulic systems are stationary and operated in a controlled environment. On the other hand, mobile hydraulic systems are designed for outdoor use and handle different loads and weather conditions.

What is the ideal time for mobile hydraulic services?

The right time for the maintenance depends on the manufacturer's guidelines. However, for fluid quality, component wear, and inspection for leaks should be done regularly after every 250–500 hours of use.