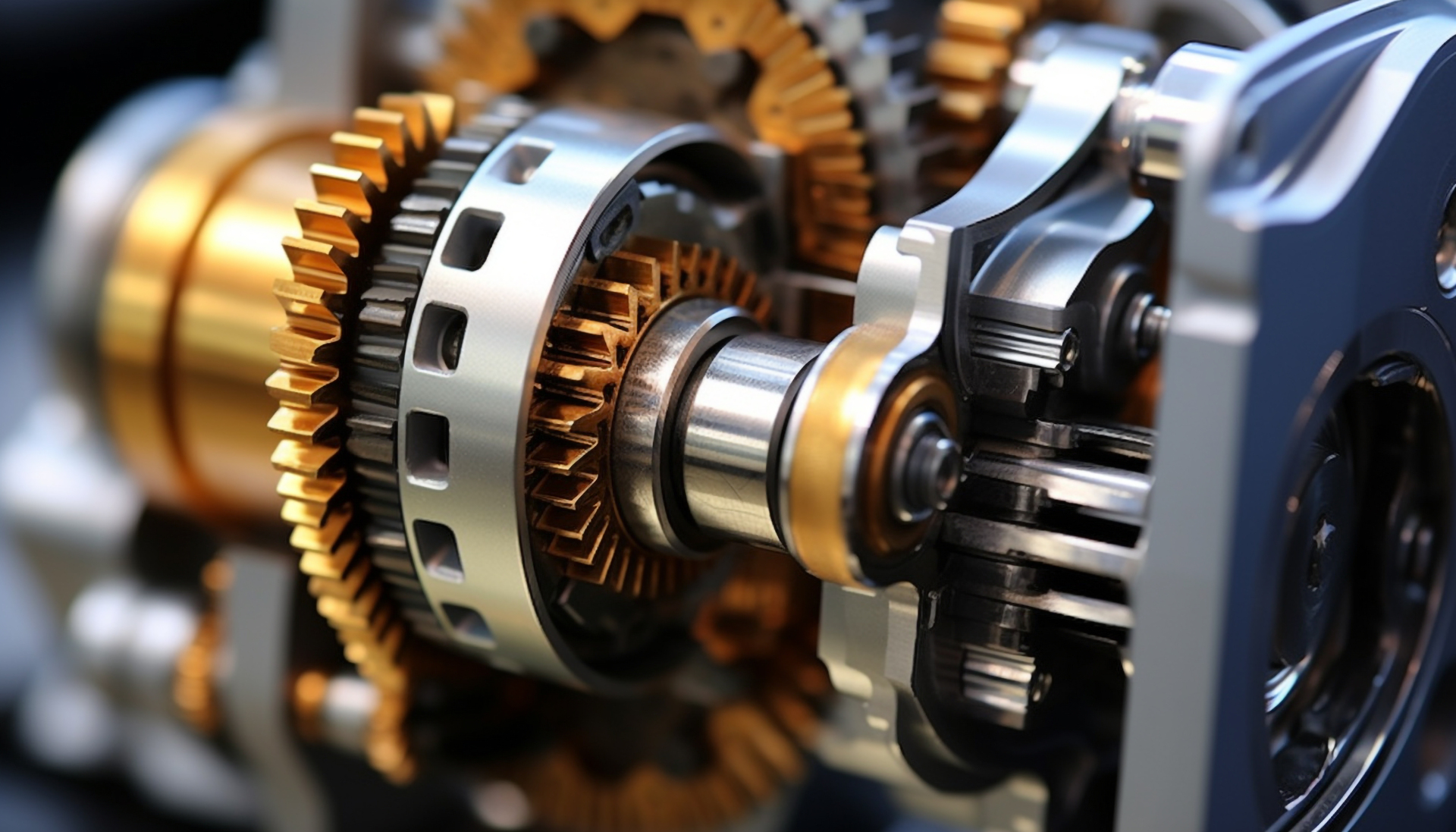

In the modern industrial setting, Planetary Gearbox for Servo Motor plays a central role in undertaking high load and high accuracy tasks. In use in robotics, automation, CNC machinery and other motion-control systems where torque and positioning accuracy are essential, these gearboxes are built on compact planetary design, high efficiency, and high load-handling capability to meet the requirements of even the most demanding tasks.

Key Elements of a Planetary Gear System

- Sun Gear: Central gear that relay the power input to the planet gears.

- Planet Gears: Wheels that turn around the sun gear.

- Ring Gear: External gears which interlock with the planet gears.

- Carrier: Frame which contains the planet gears and is attach to the output shaft.

How Planetary Gearbox Works

The planetary gearbox effectively multiplies torque while maintaining gear alignment by distributing input power across multiple planet gears simultaneously. As a result, it significantly reduces the risk of gear slip and ensures smoother operation.

This enhanced efficiency and balance make the planetary gear system particularly advantageous for servo motors. Furthermore, it proves especially beneficial in compact industrial applications, where both power and precision are critical for optimal performance.

Key Benefits of Planetary Gear Mechanism

- High Torque Transmission: The heavy-duty industrial gearbox solutions are achieve by the even distribution of the load among the multiple planet gears.

- Compact Planetary Gearbox Design: The positive power to size ratio enhances efficiency and guarantees significant space saving advantages, especially in robotic arms, CNC systems and servo motors.

- Precision and Low Backlash: The features are essential in servo applications, as they ensure synchronization and maximum performance of automation-focused systems.

- Increase Load Capacity: The evenly space loading amongst the planet gears is particularly appropriate to vertical loads and high start-stop cycles.

Industrial Applications

The planetary gearboxes are commonly use in many industries especially where small size and high torque operating capacity is critical.

Common Applications:

- Robotics: Small gearbox + precision = more comfortable control of movements.

- CNC Machines: Servo integration of the correct tool positioning.

- Packaging Machinery: Rapid and accurate repeatability.

- Automated Conveyors: Uninterrupted power supply under the load.

- Medical Devices: Compact, silent and efficient.

GFT Planetary Gearbox

The GFT Planetary Gearbox stands out as a heavy-duty, rugged off-road application in mobile machinery.

The GFT gearbox is widely recognize as one of the most reliable gearboxes, thanks to its high torque output and compact size. Consequently, it is extensively use in various construction machinery, including excavators, track drives, and winch systems.

Moreover, its integration within a planetary gear system allows it to transmit torque smoothly, ensuring consistent performance. This design not only enhances power efficiency but also contributes to the gearbox’s durability, especially under harsh and demanding operating conditions.

In addition, when applied in crawler drives and swing mechanisms, the GFT planetary gearbox delivers efficient power transfer and ensures a long service life, making it a preferred choice for heavy-duty applications.

Choosing the Right Precision Planetary Gearbox

When choosing a precision planetary gearbox, several parameters should be paid special attention to:

Tips to Choose the Right Gearbox:

- Torque Requirements: Torque needs should be close to the output of the motor.

- Backlash Levels: The level of backlash must be equal to the accuracy of positioning necessary.

- Gear Ratio: Select base on power and speed of application.

- Increasing Compatibility: Take into consideration mounting specifications, particularly, servo motors.

- Environmental Conditions: Dust, heat or vibration may affect design decisions.

Planetary gearbox in servo motor systems has to support dynamic loads efficiently and provide smooth torque without hitch and mechanical strain.

Advantages of Using Planetary Gear Reducer

Using a planetary gear reducer in servo motor applications improves overall performance in the following ways:

- Reduced friction.

- Less energy used.

- More torque in a reduced footprint.

- Extended life of equipment.

- Dynamic systems stability.

Why a High Torque Planetary Gearbox Is Ideal for Heavy-Duty Use

Planetary Gearbox with the ability to provide ultrahigh torque is a unique advantage in situations where high workloads need to be accommodated without increasing the size of the motor. Increasing the torque without increasing the physical size, the High Torque Planetary Gearbox is of unique importance in automated presses, lifting systems and large conveyors.

Conclusion: THM Huade’s Gearbox Solutions

In our products, the Planetary Gearbox for Servo Motor is a good example of this concept, delivering the highest power density in a small package available in the industry. The gearbox has been described as high-torque-capacity, effective load-distribution, and durable construction, which make it essential to contemporary machinery.

THM Huade provides Planetary Gearbox solutions as an engineering leader that addresses the diverse needs of servo applications, automated systems, and heavy-duty applications. Our products consist of high torque planetary gearbox, precision planetary gearbox, and industrial gearbox solutions, and we provide reliable options depending on the need of each customer.

FAQs

Q1. What is a planetary gearbox used for?

The planetary gearbox is use where high torque, accurate movement, and a smaller spatial envelope is require; examples include servo motors, robotics and CNC machines.

Q2. How does a planetary gearbox improve servo motor performance?

A servo motor performance is enhance by the use of a planetary gearbox in terms of increase torque, reduce motor load and improved accuracy of motion.

Q3. What is the advantage of a compact planetary gearbox design?

Compact architectures are superior because they provide high torque and small footprint that can be beneficial in machinery with limited space.

Q4. Why choose a precision planetary gearbox over a standard one?

The precision planetary gearboxes have been found to be superior to the conventional ones due to the fact that they have lower backlash, higher efficiency, and finer control which is essential to motion sensitive systems.

Q5. What makes a planetary gear system more efficient than other gear types?

The very nature of the planetary gear arrangement itself offers greater efficiency, by spreading the load over many contact points to spread the stress and increase the efficiency of transferring torque.