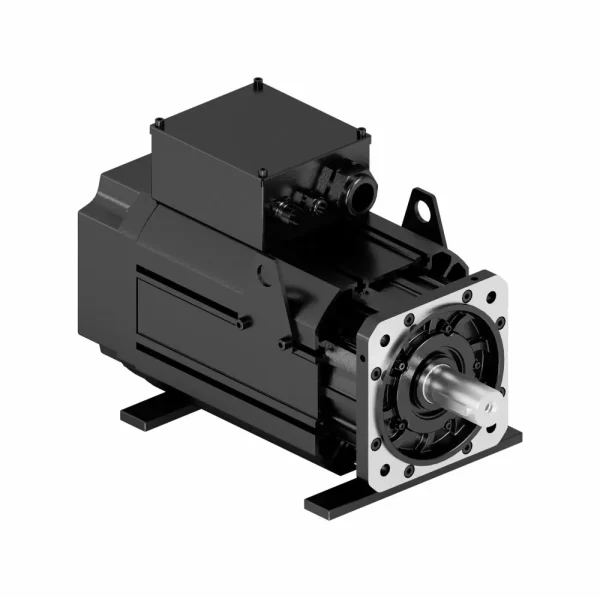

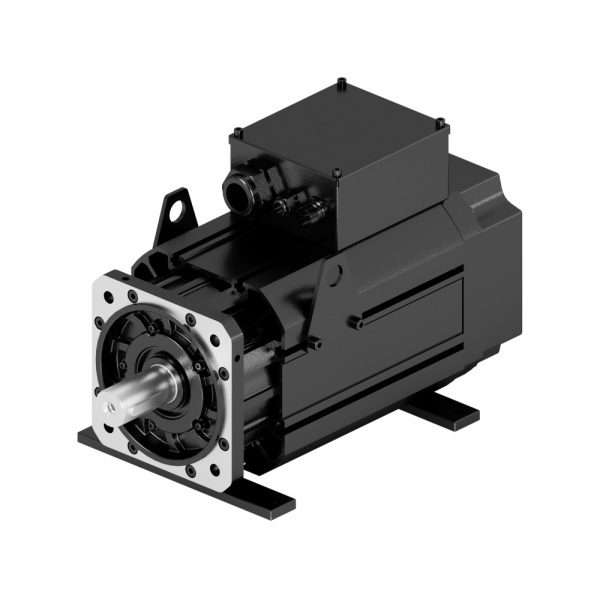

Description

When it comes to precise, efficient, and reliable motion control, nothing matches the versatility of a servo motor. Whether you are into industrial automation, robotics, CNC machines, or hobby electronics, servo motors are everywhere. From small DIY projects to large-scale production, these compact yet powerful devices deliver remarkable accuracy and smooth performance.

A servo motor is a rotary or linear actuator designed to control the angular or linear position, velocity, and acceleration of any mechanical system. Unlike traditional motors, the servo motor working principle relies on a closed-loop feedback system, which ensures your motor moves exactly as intended. Thanks to an integrated sensor, controller, and motor, the servo corrects its path in real-time until it reaches the desired position.

In India, industries ranging from automotive to electronics and aerospace have embraced the efficiency of servo motors in India. Their increasing demand in the Indian market highlights their proven track record of enhancing automation and reducing human errors.

Types of Servo Motors: Which One Fits Your Needs?

There are various types of servo motors to suit every requirement — whether it’s speed, size, or power you’re after.

- AC Servo Motor: Ideal for high-power applications and consistent torque.

- DC Servo Motor: Perfect for small machines and budget-friendly automation setups.

- Mini Servo Motor & Small Servo Motor: Lightweight and compact, these are popular in robotics, drones, and RC vehicles.

Popular models like the MG995 Servo Motor and Servo Motor SG90 have become favorites among hobbyists for their durability, accuracy, and easy servo motor connection with microcontrollers like Arduino or Raspberry Pi.

Why Choose a Servo Motor?

One of the biggest reasons industries and engineers opt for servo motors is their versatility in applications. Common servo motor applications include:

- Robotics

- Automated production lines

- CNC machines

- Conveyor systems

- Drones and RC models

Because servo motors combine a motor with a position feedback system, they can handle real-time adjustments with impressive speed and minimal error. This feature sets them apart from stepper motors, especially when tasks demand continuous and precise movement.

A servo controller plays a vital role in the operation of a servo system. The controller receives signals, calculates positioning data, and sends precise commands to the servo motor. Whether you are setting up an AC servo motor for a factory machine or a DC servo motor for a school project, the controller ensures smooth and accurate performance.

Understanding Servo Motor Price and Value

While the servo motor price varies based on size, type, and capabilities, investing in the right motor guarantees long-term value. Mini models like Servo Motor SG90 are affordable and excellent for prototypes, whereas industrial-grade AC servo motors offer unmatched durability for heavy-duty tasks.

If you’re considering automation, motion control, or even just upgrading a hobby project, understanding servo motor connection and working principles can save time and ensure optimal results.

Ready to power your next project with precision? Choose high-quality servo motors from THM Huade Hydraulics Pvt Ltd and bring your machines to life today!

Reviews

There are no reviews yet.