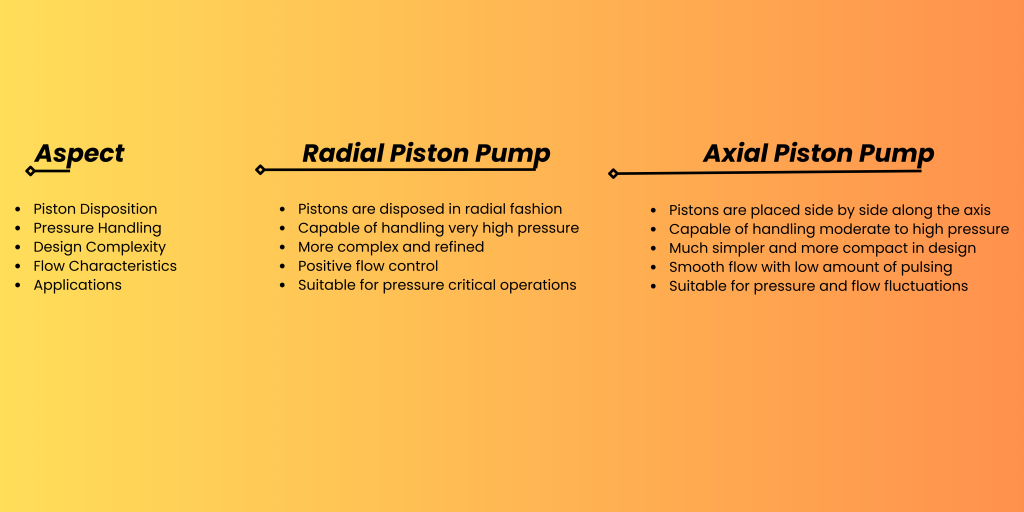

Piston pumps are one of the most important hydraulic systems as they provide high efficiency, reliability, and power density. Two of the most common pumps are Radial Piston Pumps and Axial Piston Pumps and they vary in their characteristics, advantages, and uses. The industries that demand the best hydraulic solutions, THM Huade Hydraulics guarantees original products with the testimonials of satisfied customers all over India. This article provides an understanding of the two types of pumps, the Radial Piston Pump and the Axial Piston Pump and their working, uses and differences.

What is a Radial Piston Pump?

A Radial Piston Pump is a hydraulic pump that has its pistons mounted radially around a rotor. These pumps are well known for their durability and high pressure capabilities and as such are well suited to many industrial applications.

Features of Radial Piston Pumps:

– High Pressure Capability: Capable of withstanding pressure up to 700 bar and above.

– Compact Design: Provides a compact solution for hydraulic systems.

– Durability: These products are well renowned for their long service life, even under severe conditions.

– Precise Flow Control: It helps to maintain the accuracy in all the systems that require a lot of accuracy.

Applications of Radial Piston Pumps:

Machine tools

Processing equipment for plastics

Printing and clamping equipment

Hydraulic systems at high pressure

What is an Axial Piston Pump?

An Axial Piston Pump is characterized by pistons positioned in parallel to the axis of rotation of the pump. These pumps can be obtained in fixed displacement and variable displacement types and thus can be utilized in a number of industries.

Features of Axial Piston Pumps:

– Efficiency: It provides high volumetric efficiency and work with a minimal vibration.

– Flexibility: Also available as fixed displacement axial piston pumps or variable displacement pumps.

– Compactness: It comes with a smaller size than most of the pump types available in the market.

– Reliability: Operates effectively in various sectors of the industrial market.

Applications of Axial Piston Pumps:

– Mobile plants (for example, excavators, loaders).

Industrial hydraulic systems

Manufacturing of aerospace and marine products – Energy efficient hydraulic systems

Key Differences Between Radial and Axial Piston Pumps

Benefits of using Radial Piston Pumps

1. Superior Pressure Capability: High pressure resistant products ideal for applications that require high pressure.

2. Longevity: This is due to the construction of the device to withstand the conditions of the environment.

3. High Precision: It gives the correct flow rates which are very crucial in delicate processes.

The benefits of Axial Piston Pumps

1. Energy Efficiency: Especially with variable displacement models, these pumps help to save energy.

2. Compact Size: Ideal for use where space is a limiting factor.

3. Versatility: They are common in many industries because they can be designed to fit different applications.

Why THM Huade Hydraulics?

1. Authenticity Guaranteed: All the products sold by THM Huade Hydraulics are original, guaranteeing their performance and durability.

2. Diverse Range: From Radial Piston Pumps to Fixed Displacement Axial Piston Pumps you will find everything at THM Huade Hydraulics.

3. Customer Satisfaction: The brand has a strong customer following throughout the country, and is now associated with reliability and standards.

4. Expertise and Support: THM Huade Hydraulics also offers customers technical advice on which pump will be most suitable for them.

Selection of Piston Pump

When deciding between a Radial Piston Pump and an Axial Piston Pump, consider the following factors:

1. Pressure Requirements: For very high pressure, choose a radial piston pump.

2. Space Availability: Axial piston pumps are suitable for use in compact systems.

3. Energy Efficiency Needs: Select from a fixed displacement or variable axial piston pump for energy efficient tasks.

4. Application Type: You should choose a pump type that will meet your industry needs.

Conclusion

Radial Piston Pumps are absolutely essential in the hydraulic industry while Axial Piston Pumps are highly valued due to their specific characteristics of operation. Knowing all the features and the way they might be used, businesses can make the right decisions concerning their hydraulic systems.

When it comes to THM Huade Hydraulics, the customer is guaranteed original products, high quality, and customer satisfaction. Whatever your requirements are, for a strong Radial Piston Pump or a high-performance Fixed Displacement Axial Piston Pump, THM Huade Hydraulics is your ideal hydraulic solution provider.