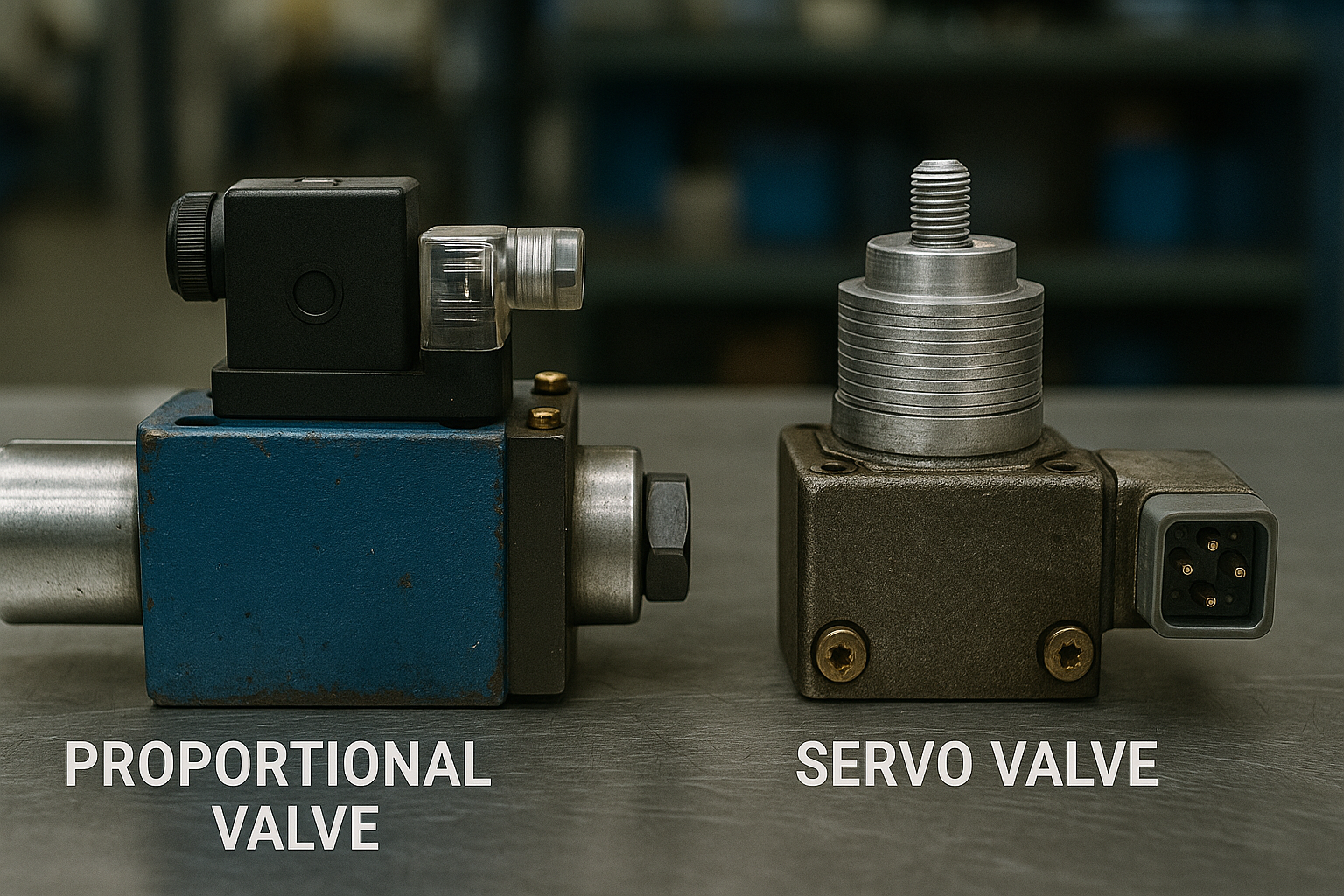

Valves of a hydraulic servo control system play an integral role in controlling the fluid flow, pressure, and direction. There are many types of valves available, namely servo valves and proportional valves, widely used during work that requires precision and flexibility. Choosing the right type of valves is important as it can directly impact the performance of your hydraulic servo control system.

Understanding the difference between Servo and proportional valves is essential while setting up a new hydraulic servo control system or upgrading an existing one. In this blog, we will explore Servo valves or proportional valves, and which option is best suited for your application.

What Are Servo Valves?

Servo valves are advanced components used in hydraulic Servo control systems where high accuracy and fast response are essential. These types of valves are the preferred choice for high-performance applications. These valves offer exceptional precision, repeatability, and fast frequency response, making them ideal for systems looking for tight control and smooth motion.

These valves work with sophisticated electronics and are typically part of the closed-loop control system. Their ability to make fine adjustments based on real-time feedback helps them to maintain exact flow and pressure conditions in dynamic environments.

Let’s take a look at the pros and cons of choosing servo valves:

Servo Valves – Pros

- High precision and fast response: These valves are ideal for applications that require tight control and accuracy.

- Smooth and stable operation: They are also great for tasks that require consistent hydraulic servo control.

- Excellent performance in dynamic systems: They are capable of handling quick loads and complex motion sequences effectively.

Servo Valves – Cons

- Higher cost and complexity: These valves are expensive to buy and install.

- Requires very clean hydraulic fluid: Even small particles in the oil can damage the sensitive internal parts, leading to frequent maintenance.

- Challenging to maintain and set up: They often require expert knowledge to install, tune, and repair, which might not be ideal for all users.

What Are Proportional Valves?

Proportional valves are a smart solution for hydraulic servo control systems

that require variable speed and flow. In comparison to traditional valves with fixed positions, proportional valves allow infinite positioning of the spool using stroke-controlled or force-controlled solenoids. This ensures precise flow and speed adjustment as per the electrical signal received.

One of the biggest advantages of proportional valves is their ability to combine directional and flow control into a single unit. This eliminates the need for various hydraulic components and simplifies the circuit design. Proportional valves also offer smooth acceleration and deceleration, which enhances safety and productivity. As a result, they also play an important role in modern hydraulic servo control systems.

Let’s take a look at some of the pros and cons of proportional valves:

Proportional Valves – Pros

- Cost-effective and user-friendly: These valves are generally more affordable and simpler to use.

- Tolerating moderate fluid conditions: They can also perform well when the hydraulic oil isn’t perfectly clean.

- Great for general-purpose use: Suitable for tasks like controlling flow or pressure in standard machinery without needing ultra-fine adjustments.

Proportional Valves – Cons

- Limited accuracy: It is not the best choice for applications where precision and speed are critical.

- Slow response time: They are not quick enough for high-speed automation or systems with rapidly changing tools.

- May require additional tuning for stability: In some cases, these valves need manual calibration to deliver smooth performance over time.

The Key Difference Between Servo And Proportional Valves

There are the main differences between servo valves and proportional valves:

| Feature | Servo Valves | Proportional Valves |

| Precision | Very High | Moderate To High |

| Response Time | Fast | Slower |

| Cost | Expensive | More Affordable |

| Maintenance | Required Clean Fluid | More Tolerant To Contamination |

| Complexity | High | Lower |

How To Choose The Right Valves For Your Hydraulic Control System

Choosing between servo and proportional valves depends on practical factors:

Precision requirements: If your hydraulic servo control system needs exact movement or positioning, go with servo valves.

Budget limitations: If you are working on a title budget, then proportional valves will be a cost-effective solution, as servo valves are more expensive.

Type of application: Choose servo valves for high-performance machines like stimulators or robotic arms. For applications like controlling, pressing, or conveyor, proportional valves work fine.

Maintenance capability: Proportional valves might be a great fit if you are not able to handle delicate components and fluid cleanliness.

Note: Take time to match the valve to your hydraulic servo control system’s needs, as it can save you money and improve efficiency in the long run.

Conclusion

Both types of valves have their strengths and are ideal for use in hydraulic servo control systems. Servo valves are unbeatable in precision, whereas proportional valves provide a good balance between performance and affordability. Choosing the right valve depends on your system’s needs, budget, and level of control required. If you are still unsure about which is ideal for your application, consult with the hydraulic specialist who can help you make it better.

If you are looking for reliable, high-performance hydraulic valves, then you can explore THM Huade, your trusted partner in hydraulic control solutions. Here you can explore the advanced range of servo and proportional valves.

Frequently Asked Questions

What are the main technical differences between proportional valves and servo valves?

The main technical difference between proportional and servo valves is their feedback mechanisms and resulting precision.

What are the advantages of servo valves over proportional valves?

Servo valves have smaller input power, in the range of tens of mA, and a higher level of accuracy.

What is the use of proportional valves in a hydraulic system?

Proportional hydraulic valves are able to control the opening to flow proportionally instead of gradually.