When designing a hydraulic system, one concern always stands out: what should you choose, a small hydraulic pump or a large pump? No matter what pump you select, this decision can have a significant impact on your machine efficiency, power output, and even cost. Identifying the balance between size, flow rate, and performance is vital in choosing the best pump configuration that suits your needs.

A compact electric hydraulic pump, an efficient internal gear pump, or a high-flow hydraulic pump (or motor), and this guide will cover everything you need to know.

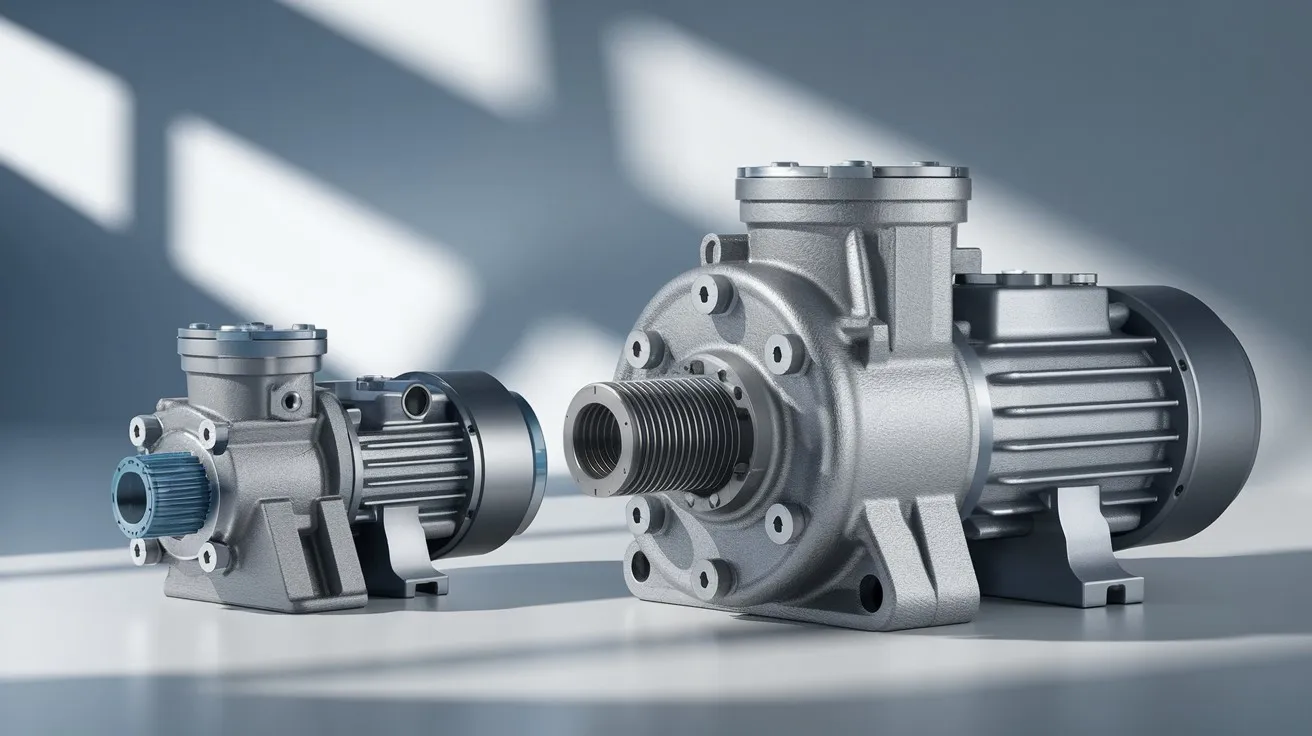

Comparing Small Vs. Large Hydraulic Pumps

To choose between a small hydraulic pump and a large hydraulic pump, it is essential to first grasp their intended application. A small hydraulic pump is compact, light, and energy-efficient, suitable for low to mid-power jobs. On the other hand, large pumps are built for heavy-duty applications that require high flow and pressure.

Small Hydraulic Pumps

A small hydraulic pump offers exceptional and efficient performance with low flow rates, ideal for mobile equipment, farming tools, and small automation applications with hydraulics. Delivering up to 300 bar of pressure, with negligible energy consumption loss, the small hydraulic pump is lightweight, space-saving, and exceptionally quiet, even quieter when paired with internal gear pumps.

Small hydraulic pumps require low maintenance and are easy to install, making them ideal for applications that need integrated simplicity with improved efficiency, control, and compactness.

Large Hydraulic Pumps

A large hydraulic pump is built for heavy-duty power and endurance. Capable of delivering high flow rates and pressures exceeding 700 bar, it drives demanding applications such as construction machinery, industrial presses, mining rigs, and marine systems.

While it consumes more energy, its output and long-term performance are unmatched, making it the ideal choice for extreme, high-pressure, and continuous-duty environments.

How a Small Hydraulic Pump Powers Compact Systems

Small hydraulic pumps are intended for situations where exactness, size, and efficacy are more important than raw power. These pumps are commonly found in mobile light construction equipment, agricultural equipment, test benches, and small industrial systems.

Most small hydraulic pumps are internal gear pump configurations providing a smooth and continuous flow of fluid that is ideal for any equipment design where noise and vibration are a concern, such as medical or alternative compact automation designs.

Advantages of Small Hydraulic Pumps:

- Energy Efficient: Utilizes lower power levels, all while still providing stable pressure.

- Compact Size: Ideal for mobile or space-constrained systems.

- Ease of Control: Compatible with proportional valves and small electric hydraulic pumps.

- Noise Reduction: Internal gear pumps operate quietly with minimal vibrations.

These factors make small hydraulic pumps a good choice when looking to design modern, portable, efficient systems.

Advantages of Large Hydraulic Pumps

Large hydraulic pumps are the king of heavy-duty labor. They can be found in industrial presses, excavators, mining equipment, and marine applications, producing significant amounts of power. When moving between locations, these pumps have high flow rates, high pressure under load, and can easily deal with viscous or contaminated fluids.

While the large hydraulic pumps have limitless output potential, they have a few downsides: increased energy consumption, higher costs, and more maintenance. In the end, when brute force and nonstop running are necessary, large hydraulic pumps are second to none.

Hydraulic Pumps and Motors: The Heart of Motion

The effectiveness of any hydraulic system is directly related to the interaction between its hydraulic pumps and motors. Pumps convert mechanical energy into hydraulic energy, while motors convert hydraulic energy back into rotational motion. The working relationship between the pumps and motors determines the system’s smoothness and delivers torque, speed, and responsiveness.

In smaller systems, small hydraulic pumps working with small motors provide adequate torque and stable operation. Larger systems use high-capacity pumps and motors that can manage the greater volume of fluid and heavy workloads for longer periods.

The most popular configuration in a minimalist design is an internal gear pump. Internal gear pumps are commonplace in both small and large pump/motor systems, largely due to their efficiency and quiet operation.

In the end, the application is durable and dependable, producing repeatable, predictable motions in automated and precision control systems, such as variable speed control systems.

Electric Hydraulic Pumps – Combining Precision and Power.

When energy efficiency and automation are a priority, an electric hydraulic pump is an obvious choice. These pumps utilize an electric motor through hydraulic circuits, permitting speed regulation, sound reduction, and emissions.

Benefits of Electric Hydraulic Pumps:

- Energy Efficiency: Match the speed of the motor to expected demand to minimize power waste.

- Low Maintenance: Electric hydraulic pumps have fewer moving parts than engine-driven pumps.

- Clean Operation: No exhaust, and no oil leaks, these pumps are ecologically friendly!

- Quiet: Electric hydraulic pumps are perfect for working inside or within a precision-type device.

An electric hydraulic pump can easily be incorporated to supplement or replace existing hydraulic pumps, especially in automated or manufacturing environments where consistent power and regulated precision are needed.

Comparison of Top Models: Small vs. Large Hydraulic Pumps

Below, I’ve listed several of the leading models and brands addressing small and large hydraulic pump needs:

Small Hydraulic Pumps

- Parker PGP620 Series: These compact gear pumps are used in small machines and could be attached to other automation systems.

- Eaton 260 Series: Lightweight and durable, but not overly heavy-duty. Designed for moderately high pressure and not overly high speeds.

- Bosch Rexroth AZP Gear Pump: Small but efficient. Known to provide smooth operation and last a long time.

Large Hydraulic Pumps

- Bosch Rexroth A10VO Axial Piston Pump: This is a special type of hydraulic pump designed for high-pressure applications, and many are specifically designed for mobile hydraulics.

- Parker PV Plus Series: Heavy-duty hydraulic pumps. These models are designed for low noise, high volumetric efficiency, and long service life.

- Eaton Hydrokraft PVW Series: These are power house hydraulic pumps and are typically used for industrial purposes. Internal hydraulic systems are designed for handling loads on continuous duty cycles.

Electric Hydraulic Pumps

- Enerpac E-Pulse Series: Usually small and portable, but efficient enough for small maintenance or testing task setups.

- HYDAC DHP Compact Pump: A small electric pump that is designed with quiet operation and a high level of controllability for industrial-purpose hydraulic systems.

- SPX Power Team PE55: A robust electric model. Modular too; many flow options and electric setup options will vary in flow capacity.

These models represent some of the best options for their respective categories, combining efficiency, durability, and adaptability.

Final Thoughts

Ultimately, the appropriate pump is determined by your particular system requirements. A small hydraulic pump is perfect for tight, energy-efficient systems that require precision and control, while a large hydraulic pump is designed for heavier turnkey, powerful systems where performance and reputation matter most.

In need of the ideal hydraulic system? Contact THM Haude today, and our expert team will help you optimize your pump for system performance, reliability, and efficiency.

FAQs

Q2. When is it appropriate to use a large hydraulic pump?

A2. Large hydraulic pumps are most suitable for heavy-duty hydraulic systems requiring high flow and pressure. Examples of this type of application include industrial machinery and construction equipment.

Q3. What are electric hydraulic pumps typically used for?

A3.Electric hydraulic pumps operate quietly, efficiently, and provide precise control; therefore, they are very commonly used in automation and industrial systems.

Q4. What are the benefits of using internal gear pumps within hydraulic systems?

A4.Internal gear pumps provide a smooth, low-pulsation flow and high reliability while taking up little space. They are excellent for small hydraulic systems, as well as larger hydraulic setups with multiple pumps.

Q5. Can small hydraulic pumps operate in high-pressure applications?

A5. Small hydraulic pumps can achieve pressure levels of up to 300 bar, but they function best in lighter, precision applications.

Q6. How do I know if I should choose a small or a large hydraulic pump based on the system?

A6. To help determine which pump works best for your system, you should consider the load, flow rate, power requirements, and the available space for the pump.