The hydraulic motors are important in industrial equipment, construction equipment, and mobile applications. The right one ensures maximum performance, efficiency and durability. In this guide, we will unravel the main specifications that you should look at before you purchase a hydraulic motor.

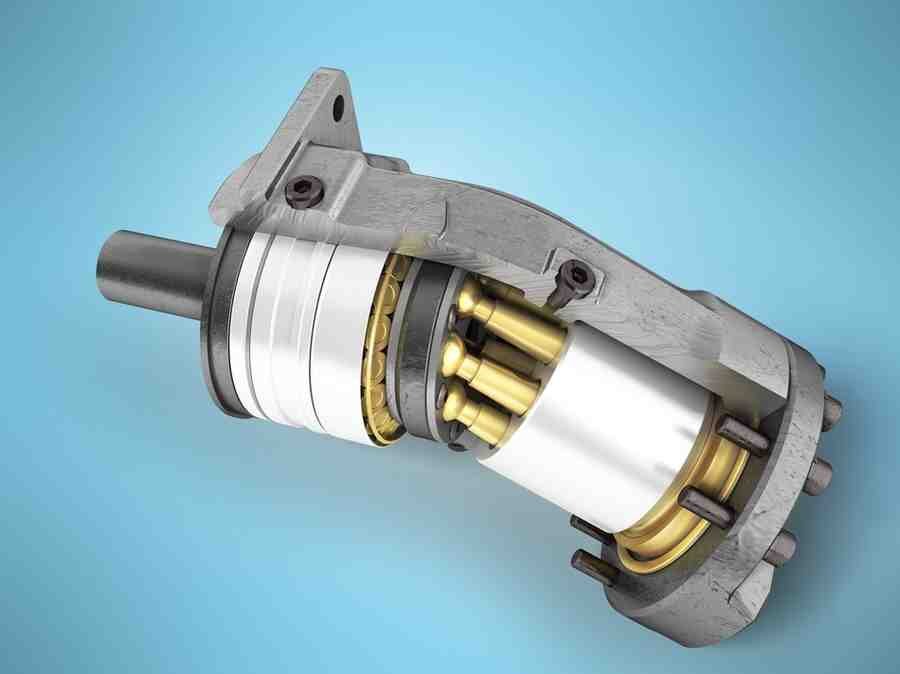

Understanding Hydraulic Motors

Hydraulic motors convert hydraulic pressure and flow to torque and rotational motion. They are widely applied in industries because of high power density, durability, and reliability.

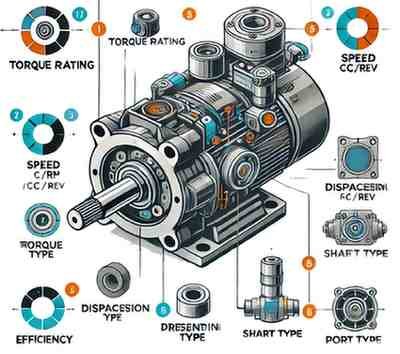

Important Specifications to Look at Before Purchasing a Hydraulic Motor

1. Torque Requirements

- Start-up torque: The motor needs enough starting torque when it is turned on.

- Continuous torque: It will give you the torque you need for your job, plus a little extra.

- Peak torque: Machines that may get more weight suddenly will benefit from this.

- High torque comes from hydraulic motors with bigger displacements.

2. Speed (RPM)

- Determine the highest and lowest speed range of your application.

- Compact machines will need Compact hydraulic motor with lower speed but higher torque.

3. Displacement

- Displacement tells how much the fluid is required for one revolution.

- Cubic centimeters per revolution is used.

- The more displacement, the more torque, but the speed goes down.

4. Flow Rate and Pressure

- Look at the motor’s rated flow rate to make sure it is in L/min or GPM.

- Make sure the flow rate works with your system’s pump.

- It is important that the maximum operating pressure (bar or PSI) matches the limits of your system.

5. Efficiency

- Look for the amount of leakage and friction loss in the motor.

- Motors that are efficient use less energy and put out less heat.

6. Mounting Type

- Confirm the correct mounting style: flange, foot, or face-mounted.

- It should go well with the mounting style of your machine or application.

7. Shaft Type and Size

- There are keyed, splined, or tapered shafts available.

- Make sure the shaft is strong and works with the rest of your system.

8. Size and Weight

- Compact hydraulic motor is suitable for space-constrained applications.

- Lighter motors are used to help reduce the weight of mobile equipment.

9. Hydraulic Motor Maintenance

- Select motors that can be maintained and repaired easily.

- Search for units that have interchangeable parts and easy to open seals.

10. Temperature Range

- Ensure that the motor will be able to run efficiently in your expected temperature range.

Types of Hydraulic Motors

When you know the types, you can pick the right motor for your use.

Gear Motors:

Low cost

Simple design

Best for use with low to medium pressure

Vane Motors:

Good speed control

Medium efficiency

Common in industrial systems

Piston Motors:

High efficiency

Works well with high levels of pressure and torque.

You will often find them in industrial hydraulic motor systems

Hydraulic Motor vs Electric Motor

| Feature | Hydraulic Motor | Electric Motor |

| Torque | High torque at low speed | Needs gearbox for high torque |

| Size | More compact in high-power applications | Larger for same power output |

| Efficiency | High, especially in heavy-duty conditions | High in steady-state use |

| Environment | Performs better in harsh conditions | Sensitive to dust, water, and shock |

| Maintenance | Regular fluid checks required | Lower routine maintenance |

Applications of Hydraulic Motors

- Construction Equipment

- Agricultural Machinery

- Injection Molding Machines

- Conveyor Systems

- Marine Winches

- Industrial Automation Systems

Guidelines in Finding Dependable Hydraulic Motor Suppliers

- Seek certified hydraulic motor suppliers with a good name.

- Ask them whether they are able to provide custom solutions for you.

- Ensure they provide after sale support and have spare parts.

- Compare the characteristics of hydraulic motors before making a choice depending on price.

Hydraulic Motor Maintenance Best Practices

- Regular fluid checks: Maintain clean hydraulic oil.

- Check seals and hoses for leaks.

- Monitor noise and vibrations: Unusual behavior may signal wear.

- Have regular servicing to ensure it lasts long.

Conclusion – Smart Buying Starts with the Right Specifications

It is important to check torque, speed, displacement, and system compatibility before picking a hydraulic motor. Having this information lets you pick the correct hydraulic motor for either heavy industry or a small space. THM Huade Hydraulics supplies a variety of reliable and high-performance hydraulic motors that are made to match your specific application needs with accuracy and toughness.

FAQs

Look at torque, speed, displacement, flow, pressure, and the kind of application you need. Go with the options that fit your system’s requirements.

You will mainly find gear motors, vane motors, and piston motors. They all have special features that are important for different uses.

Hydraulic motors are efficient where there is need for a lot of torque and toughness. You should apply electric motors if you require operations to be accurate, clean, and quiet.

Depending on the size, type, brand, and specifications, the prices of hydraulic motor increase or decrease. Basic hydraulic motors can be purchased for anything from ₹5,000 to ₹1,00,000 and more.

THM Huade is a trusted supplier in India offering a wide range of industrial hydraulic motors, including compact, high-torque, and low-maintenance models.