Hydraulic cylinders are a vital part of many industrial machines. They power heavy equipment like construction machinery, steel manufacturing tools, and more. If you take care of them regularly, they’ll last longer, break down less often, and save you the cost of major repairs.

Here’s a simple step-by-step guide to help you maintain your hydraulic cylinder and keep it working smoothly.

Why Should You Care About Hydraulic Cylinder Maintenance?

Ignoring maintenance might seem harmless at first, but it leads to leaks, slow performance, and even complete failure of machines. Poorly maintained cylinders often cause:

- Safety risks

- Downtime in operations

- Expensive repair or replacement

On the other hand, well-maintained cylinders can function for years without major issues. They reduce repair costs and keep your machines running reliably.

Step 1: Look for Visible Damage

Before you start working with the machine, do a quick check for any clear signs of damage. Look closely for:

- Oil leaks around seals

- Cracks, dents, or scratches on the piston rod

- Rust or corrosion buildup

- Loose or broken fittings

Even small leaks or cracks can lead to bigger problems later. If you ignore them, they can turn into major repair jobs, forcing you to spend time and money unnecessarily.

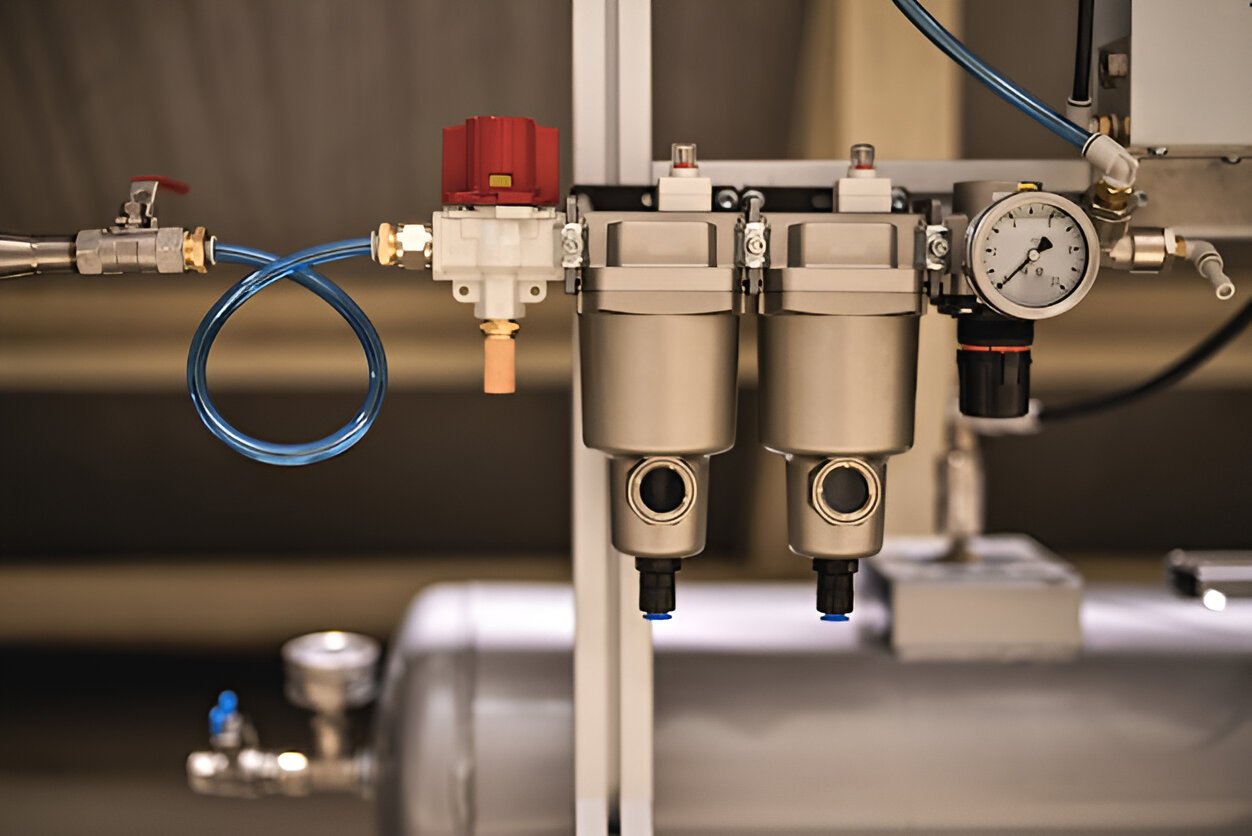

Step 2: Check the Hydraulic Fluid Level

The fluid inside the hydraulic system is like its blood. If there’s too little fluid or if it’s contaminated, the whole system suffers.

Here’s what to look for:

- Low fluid levels in the reservoir

- Fluid that looks milky or foamy (may indicate water contamination)

- A burnt smell or dark color (suggests overheating)

- Tiny metal particles (a sign of internal wear)

Contaminated fluid wears out the pistons and seals quickly. If you see any of the signs above, replace the fluid and inspect the cylinder for internal damage.

Step 3: Clean the Cylinder Regularly

Dust and dirt are the enemies of hydraulic cylinders. They can enter through seals and scratch the rod or block movement.

To prevent this:

- Clean the rod and seals after every use

- Use protective boots or covers to shield exposed parts

- Store the equipment in a clean, dry place

Some machines also have LUBE systems that monitor air filters and help reduce dust intake. Keeping things clean is one of the simplest ways to avoid early wear and tear.

Step 4: Inspect and Replace Worn-Out Seals

Seals are small parts, but they play a big role in keeping the cylinder pressurized and leak-free. Over time, they wear out.

Signs of seal wear include:

- Cracks or hardening of the material

- Fluid leaking around the piston rod

- Too much friction when the cylinder moves

- Unusual squeaking or scraping noises

If you spot these issues, replace the seals immediately. A broken seal can cause the cylinder to lose pressure and fail suddenly.

Step 5: Apply Lubrication to Moving Parts

Friction is a silent killer. Without enough lubrication, moving parts grind against each other and wear out faster.

Here’s what you should do:

- Apply high-quality grease to rod ends, joints, bushings, and pins

- Avoid over-lubrication, as extra grease can attract dust

- Follow the lubrication schedule mentioned in your equipment manual

Proper lubrication helps parts move smoothly and prevents early breakdowns.

Step 6: Test the Cylinder’s Performance

Once everything looks good on the outside, test the actual performance.

How to do it:

- Fully extend and retract the cylinder

- Listen for strange noises like grinding or squeaking

- Watch for jerky or uneven motion

- Check if the movement is too slow or too fast

If anything feels off, stop the machine and inspect further. Regular testing helps catch small issues before they become big failures.

Step 7: Fix Leaks Immediately

Even a small hydraulic leak can lead to big problems. It reduces power, affects machine performance, and may harm nearby components.

Common causes of leaks:

- Worn seals

- Cracked cylinder body

- Loose or damaged fittings

- Too much pressure in the system

Fix leaks as soon as you see them. Waiting too long can damage the entire system and cost you more in repairs.

Step 8: Check Cylinder Pressure and Alignment

Incorrect pressure or poor alignment can cause uneven wear and damage over time.

Make sure:

- The cylinder is mounted correctly

- The pressure is within manufacturer-recommended limits

- The cylinder isn’t under side loads (which can bend or misaligned it)

- All connections are tightly secured

Proper alignment ensures smoother movement and longer life for your cylinder.

Step 9: Don’t Overlook Small Cylinders

Many industries use small hydraulic cylinders for precision jobs. Though smaller, they still need just as much care.

Here’s how to maintain them:

- Check for even tiny leaks

- Ensure smooth movement with no jerks

- Keep them clean and properly lubricated

- Replace seals and gaskets when needed

Small cylinders can be sensitive to heat, vibration, or debris. Precision matters here, so take extra care.

Step 10: Follow the Manufacturer’s Repair Manual

For any complex repairs, always refer to the repair guide from the manufacturer. It tells you:

- Torque specifications

- Pressure limits

- Assembly procedures

If you’re unsure, it’s better to contact a certified professional for repairs. This helps avoid mistakes that could lead to safety risks or equipment damage.

Final Thoughts

Maintaining your hydraulic cylinders doesn’t have to be difficult, but it does need to be consistent. By following these steps:

- You’ll reduce downtime

- Avoid expensive repairs

- Improve machine performance

- And make your workplace safer

Industries like construction, steel, and plastics depend heavily on hydraulic systems. Regular maintenance protects both the machines and the people working around them.

When in doubt, always refer to the manufacturer’s guide or call a certified hydraulic cylinder repair professional. Preventive care now can save you from big problems later.

FAQs

What are the warning signs of a failing cylinder?

Look for hydraulic fluid leaks, reduced lifting power, odd noises, and slow or jerky motion. These can be early signs of internal damage or seal failure.

Can I replace seals by myself?

Yes, if you follow the right guide and the cylinder isn’t too large or under extreme pressure. For bigger jobs, always call a professional to stay safe.

How can I prevent my cylinder from overheating?

Check for proper lubrication, clean and replace old hydraulic fluid, reduce operating pressure if it’s too high, and allow the system to cool if it’s running hot. Overheating can cause serious internal damage.