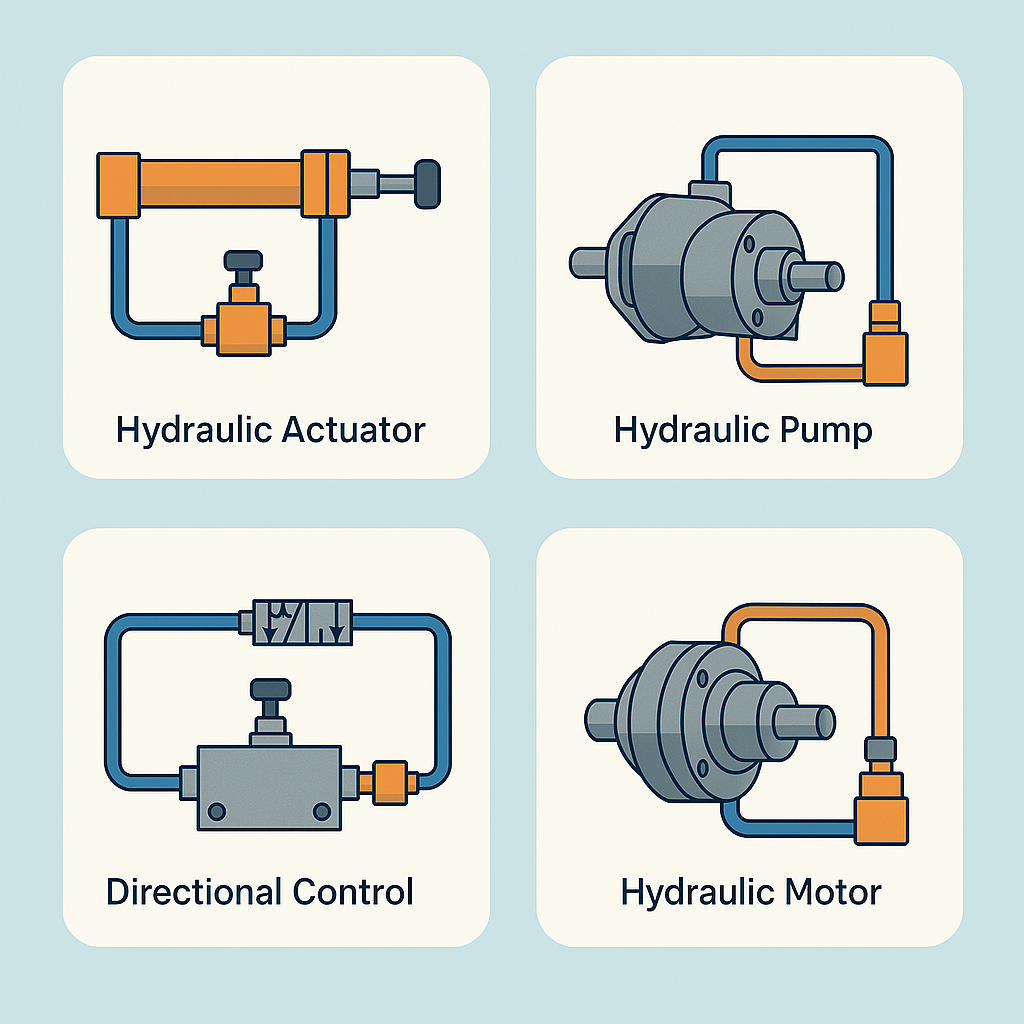

Have you ever faced delays on your shop floor due to machines overheating or behaving oddly? Most folks blame the pump or actuator. But what if the real culprit is the one small part no one notices — the flow control valve? Yes, that tiny part which decides how fast your oil flows is often the root cause.

Hydraulic flow control valves are the unsung heroes of machines in steel, cement, and plastic plants. And here’s a fact — the oil and gas industry alone eats up over 24% of the control valve market. Now imagine the demand from construction and molding sectors.

That’s where hydraulic valve adjustment matters. One wrong setting? The whole setup may act like it’s drunk.

How Hydraulic Valve Adjustment Makes or Breaks Your System

When you think of flow in a hydraulic circuit, you’re basically thinking of controlled power. You need just enough to move a part—not more, not less. Now here comes the star — hydraulic valve adjustment.

Adjusting flow valves is not guesswork. If you set it too tight, actuators lag. Set it too loose, and systems overheat or waste energy. For instance, a hydraulic flow control valve in a mobile crane must be tuned based on weight load. Same crane, different load, different setting.

What’s more, hydraulic flow valve settings impact pressure, speed, and system life. You can’t fix a bad valve tune-up with better fluid. That’s like tuning a guitar by replacing the strings but not twisting the knobs.

Precision in Construction Equipment: Hydraulic Valve Adjustment at Work

Think of an excavator. It digs, lifts, turns, drops — all in one motion. Behind this ballet of metal, hydraulic valve adjustment ensures the right amount of oil reaches the right place at the right time.

In cold climates like Canada, viscosity of hydraulic oil changes, and so must your hydraulic flow valve settings. A flow that works in summer could jam you up in winter.

Manufacturers of construction gear often face breakdowns not due to design flaws, but due to poor flow control valve hydraulic settings during installation. Even the best hydraulic flow control valve will fail if it’s not adjusted based on task and ambient heat.

Common techniques used here:

- Meter-in Control for load-sensitive systems.

- Bypass Flow when high-pressure line cannot be restricted.

- Needle Valve Tuning — fine tweaks for motion control.

If one actuator jerks while others flow smoothly, check the hydraulic valve adjustment first. Don’t blame the joystick.

Steel and Cement Plants: Managing Flow with Hydraulic Flow Valves

You can’t have downtime in a cement plant during peak mix season. Every hour lost is tons of concrete wasted. Now guess what controls the roller press, kiln lifts, and conveyor tilts? You got it — hydraulic flow control valves.

The flow control valve hydraulic usage in cement and steel plants is more demanding than in light duty systems. Loads are heavier, heat is higher, and shifts run longer. That means valve settings must factor in:

- Thermal Expansion of oil.

- Back Pressure Effects from long lines.

- Shock Load Response, especially near presses.

A wrongly set hydraulic flow valve can ruin alignment in rolling mills or cause chute doors to jam shut. Again, not a design flaw — bad valve tuning.

Some plants use load-compensated flow valves, others go with plain needle types. Both need hydraulic valve adjustment before going live.

Here’s a pro tip: Always adjust under load, never when idle.

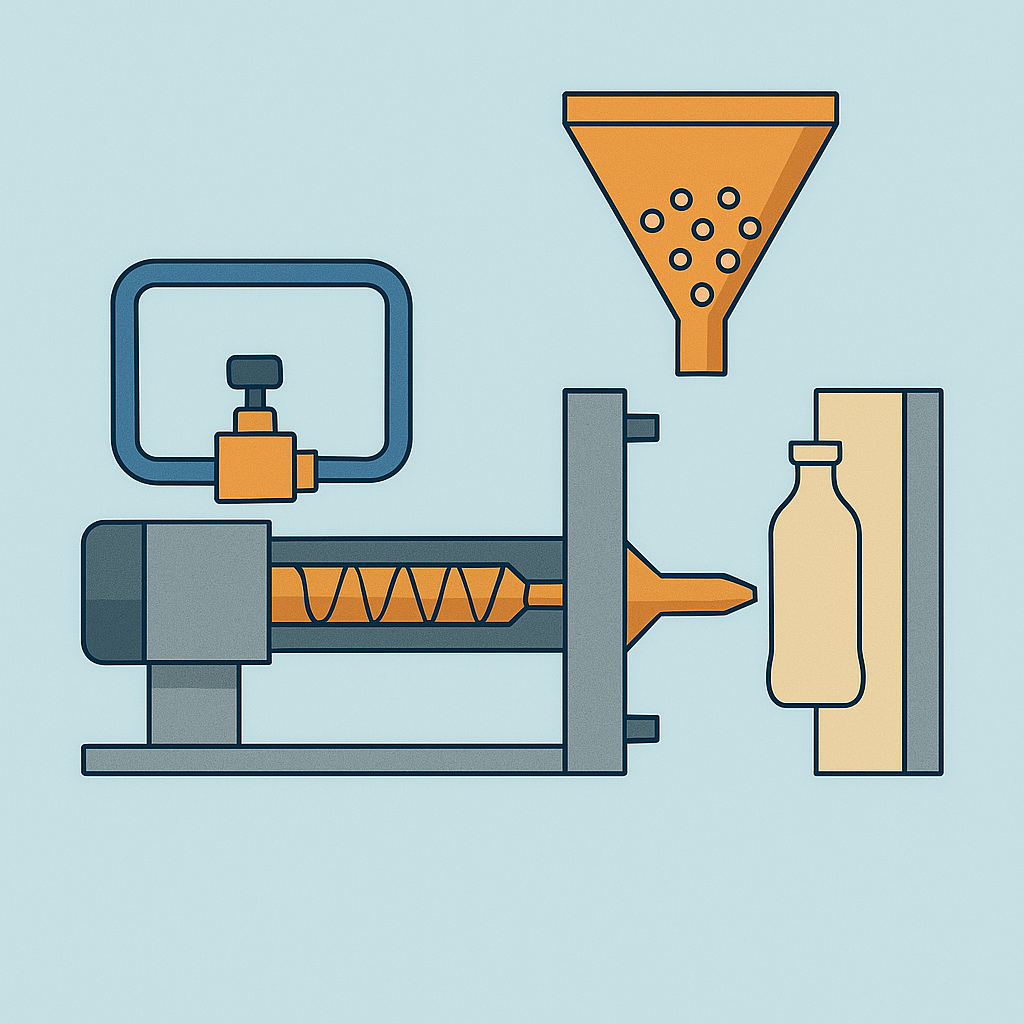

Plastic Injection Molding: Why Fine Hydraulic Flow Valve Control Matters

Molding machines deal with two flows — injection and ejection. Both need exact control or the part will have flash or won’t demold at all.

A hydraulic flow control valve that’s off by even a small margin can result in slow mold fill or short shot. That means scrap parts. In a 24-hour run, it could cost lakhs.

This is where hydraulic valve adjustment comes in. Molding machines use:

- Proportional Valves for shot speed.

- Needle Flow Valves for ejection speed.

- Pilot-Operated Valves in high tonnage units.

Flow control valve hydraulic setups in injection systems must match:

- Mold temperature

- Part geometry

- Cycle speed

So yes, adjusting your hydraulic flow valve is not optional. It’s what stands between zero scrap and full bin.

Machine Tools: Comparing Different Flow Control Valve Hydraulic Functions

When it comes to precision tools like grinders or CNCs, even a slight delay in actuation can throw off tolerances. That’s why hydraulic flow control valves are a must in many tool machines.

Here’s a quick look:

|

Valve Type |

Use Case |

Key Benefit |

Adjustment Method |

|

Needle Valve |

Simple presses, lathes |

Cheap and easy |

Manual dial |

|

Proportional Valve |

CNC, complex machines |

Precision |

Electrical input |

|

Pressure Compensated |

Consistent load tools |

Stable speed |

Internal piston setting |

|

Flow Divider |

Multi-tool operation |

Equal split |

Fixed or adjustable |

And all of these need hydraulic valve adjustment to work as expected. Don’t just install and forget.

Hydraulic Valve Adjustment Techniques for Better System Life

So, how do you do it right?

- Start with Flow Rate: Check GPM needed by the actuator. Set the valve to match, not guess.

- Use a Flow Meter: Not by ear. You need data.

- Tune Under Load: Always test with real part load, not dry run.

- Heat Matters: Recheck settings once the oil is warm.

- Go Zone-Based: Adjust valves by function — one for lift, one for tilt, etc.

Even brand-new hydraulic flow control valves need tweaking. That’s where experienced hands matter. Not all adjustments can be taught. But they can be learned.

Conclusion: Time to Get Serious About Hydraulic Valve Adjustment

Your machines may look strong. But if the hydraulic valve adjustment is off, your whole operation runs like it’s walking with a limp. Don’t let a simple mistake rob you of uptime and money.

Want help? THM Huade Hydraulics stands tall in this space. With decades in the game, they bring not just parts — but peace of mind. Trust them for valves that work right from day one.

Share this with your shop floor team and plant heads. Or forward it to your friend who’s tired of downtime.

FAQs

How do I know if my hydraulic flow valve needs adjustment?

If actuators move too fast, jerk, or lag — check valve settings. Also, monitor for heat build-up and sound.

Are there automatic flow control valve hydraulic systems?

Yes. These include proportional and servo valves. They adjust based on load and input signal.

Why do hydraulic systems in molding machines need flow control?

Because fill rate, ejection, and clamp speed must match mold design. Even small flow changes affect product shape.

How is hydraulic valve adjustment different in mobile vs industrial hydraulics?

Mobile systems see temperature swings, variable loads. Industrial ones are stable but need tighter tolerances.