Industrial equipment relies on hydraulic pumps and motors to work properly. The hydraulic performance of CNC press brakes, blow molding machines, and cement mixers depends on reliable hydraulic systems. Technical problems can occur within hydraulic systems even when they possess top-tier functionality unless they receive maintenance support.

Business operators who manufacture in North America and Canada must perform routine maintenance on all hydraulic components. The device is a fundamental requirement because it serves the dual functions of equipment protection, operational safety, and performance enhancement.

This article delivers complete guidance about hydraulic pump maintenance, which extends the life span and minimizes unexpected machine stoppages.

Top 10 Maintenance Tips for Hydraulic Pumps and Motors

1. Understand Your System Requirements

Before performing maintenance activities, become familiar with every aspect of the system. Establish a comprehensive understanding of the system by determining which hydraulic pumps and motors exist, along with their flow and pressure specifications, in addition to their recommended operational environment. Filtering your maintenance schedule knowledge with this system understanding allows timely recognition of preliminary maintenance issues.

Refer to the manufacturer’s documentation for recommended service intervals. Equipment like THM Huade’s hydraulic motors comes with clear specifications that help guide inspections.

2. Prioritize Fluid Cleanliness

System failures and premature wear will be prevented by using clean hydraulic fluid. Performance deterioration happens instantly when contaminants such as metal shavings or dust, along with water, enter the system. High-efficiency filters should be used, while replacement should happen on schedule.

You must test and examine your fluid for cleanliness compliance at scheduled intervals. Heavier fluid cleanliness leads to enhanced pump and valve operation, together with a diminished need for maintenance and replacement.

3. Monitor Fluid Levels and Temperatures

Fluid level and temperature have a direct impact on system health. Low levels may cause cavitation, while excessive heat accelerates fluid breakdown and seal damage. Use accurate gauges or digital sensors to monitor fluid levels and temperature. Maintaining optimal levels ensures consistent pressure, smooth motor operation, and minimal wear on your hydraulic components.

4. Regularly Inspect and Replace Filters

Hydraulic filters protect your system from contaminants that lead to pump or motor damage. Over time, filters clog and reduce fluid flow. Set a schedule for visual inspections and install indicators that alert you when it’s time to replace them. Changing filters at the right time ensures consistent flow, system cleanliness, and reliable performance over long operating cycles.

5. Check for External Leaks and Seal Conditions

Hydraulic leaks can reduce system pressure, increase contamination risks, and lead to costly fluid loss. Routinely inspect all seals, hoses, and fittings. Look for dampness around joints or visible oil pooling beneath equipment. Address minor leaks early to avoid pressure drops and ensure the system remains efficient and environmentally compliant.

6. Test System Pressure and Flow

Regular pressure and flow testing help detect problems before they escalate. Use diagnostic tools to compare actual performance with manufacturer specifications. Watch for reduced pressure or irregular flow patterns, which may suggest internal wear, valve issues, or pump inefficiencies. Proactive testing ensures your equipment performs reliably even under full load.

7. Keep a Maintenance Log

A comprehensive records system for inspections and maintenance activities enables better future planning of maintenance tasks. Track data such as fluid changes, filter replacements, and component performance. Simply by tracking records, you can see how components operate and anticipate their servicing needs to prevent failures and create plans for upcoming component replacement budgets.

8. Follow Startup and Shutdown Procedures

Your hydraulic system faces potential harm from incorrect procedures during system startup or shutdown. The system needs time to reach its operational temperature after start-up while also dismissing air bubbles from the fluid stream. The manufacturer provides tested procedures which enable safe pressure relief procedures during shutdown operations. The method controls pressure waves to safeguard the integrity of pumps alongside hoses and seals against abrupt, sudden forces.

9. Train Your Operators and Maintenance Crew

All systems can fail even with flawless maintenance practices. Your operators, along with technicians, should gain knowledge about hydraulic basics alongside safe handling procedures that also indicate wear signs or potential failures. Regular training sessions should be provided to maintain correct practices and their reinforcement. Team members with adequate knowledge protect equipment lifespan and create a safer working area.

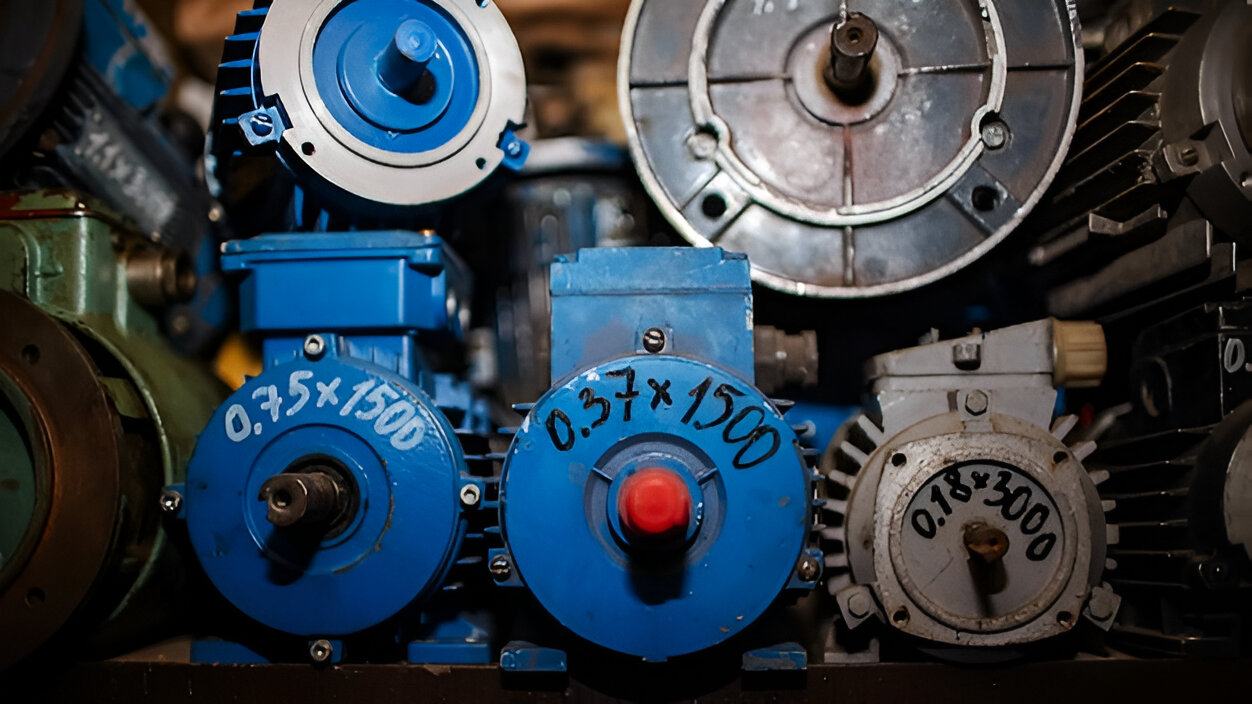

10. Invest in Quality Components

Using high-quality pumps and motors makes a noticeable difference in reliability and maintenance needs. Choose components like THM Huade’s hydraulic motors and servo systems, known for durability, efficiency, and after-sales support. Reliable equipment reduces repair frequency and ensures better long-term return on investment.

Common Warning Signs of Hydraulic Failure

Don’t wait until your machine fails. Watch out for:

- Excessive noise

- Increased fluid temperature

- Slow or jerky movement

- Visible fluid leaks

- Pressure drop or cavitation

Early intervention can prevent costly repairs and unplanned downtime.

Why Preventive Maintenance Pays Off

Reactive maintenance is expensive. Lost production, emergency repairs, and part replacements add up quickly. Preventive maintenance, on the other hand:

- Extends component lifespan

- Reduces operating costs

- Minimizes downtime

If your operation depends on press brakes, injection molding, or baling presses, you can’t afford unexpected breakdowns.

Plan Your Maintenance with Experts

Your hydraulic system is only as reliable as the care it receives. With routine maintenance, quality parts, and trained operators, you can avoid costly failures and extend the service life of your pumps and motors.

Hydraulics are the lifeblood of your machines. Keep them running strong with smart, consistent maintenance backed by expert support from THM Huade. We are experts in inspection, troubleshooting, and system optimization. This ensures your equipment stays reliable even under demanding workloads.

For top-quality components and expert advice, contact the team at THM Huade. Our range of hydraulic motors and hydraulic pump solutions supports industries across North America and Canada.

FAQ’s

What is the most common cause of hydraulic pump failure?

Pump failure results mainly from hydraulic fluid contamination. Dirt and both water contamination and metal particles destroy significant internal elements. A hydraulic system requires frequent fluid inspections and appropriate filtration components for maintaining its clean operation and high performance.

How can you extend the life of a hydraulic motor?

The lifespan of hydraulic motors expands when you practice proper fluid cleanliness along with appropriate pressure inspection and appropriate seal lubrication. Product owners should follow the maintenance intervals detailed in manufacturer guidelines to avoid sudden equipment failures and minimize premature part deterioration.

Why is hydraulic fluid maintenance important for pumps and motors?

As a lubricant, through its lubricating properties, the fluid works alongside its ability to move hydraulic power between system components. High-quality fluid with maintained cleanliness helps decrease friction while stopping overheating, which results in lower component wear. Regular fluid analysis techniques, along with proper changing schedules, enable direct enhancement of pump and motor reliability.