Do you feel stuck picking the right system for your press or drill machine?

You are not alone. Most plant heads and machine owners in North America and Canada still guess what goes wrong inside their tools. At the core of many such problems lie hydraulic pumps and motors—two small parts with a big task.

In 2024, the construction field used more pumps than any other space. This field alone held more than one-third of all pump use. That is not by luck. The demand shows how key this tech is for strong and fast machines.

Let us break this down. First, the heart—hydraulic pumps. Then, the force—Hydraulic Motors. Last, we show you how both work as one to help your plant or site run smoothly.

Why Pumps Push and Motors Move Your Machines

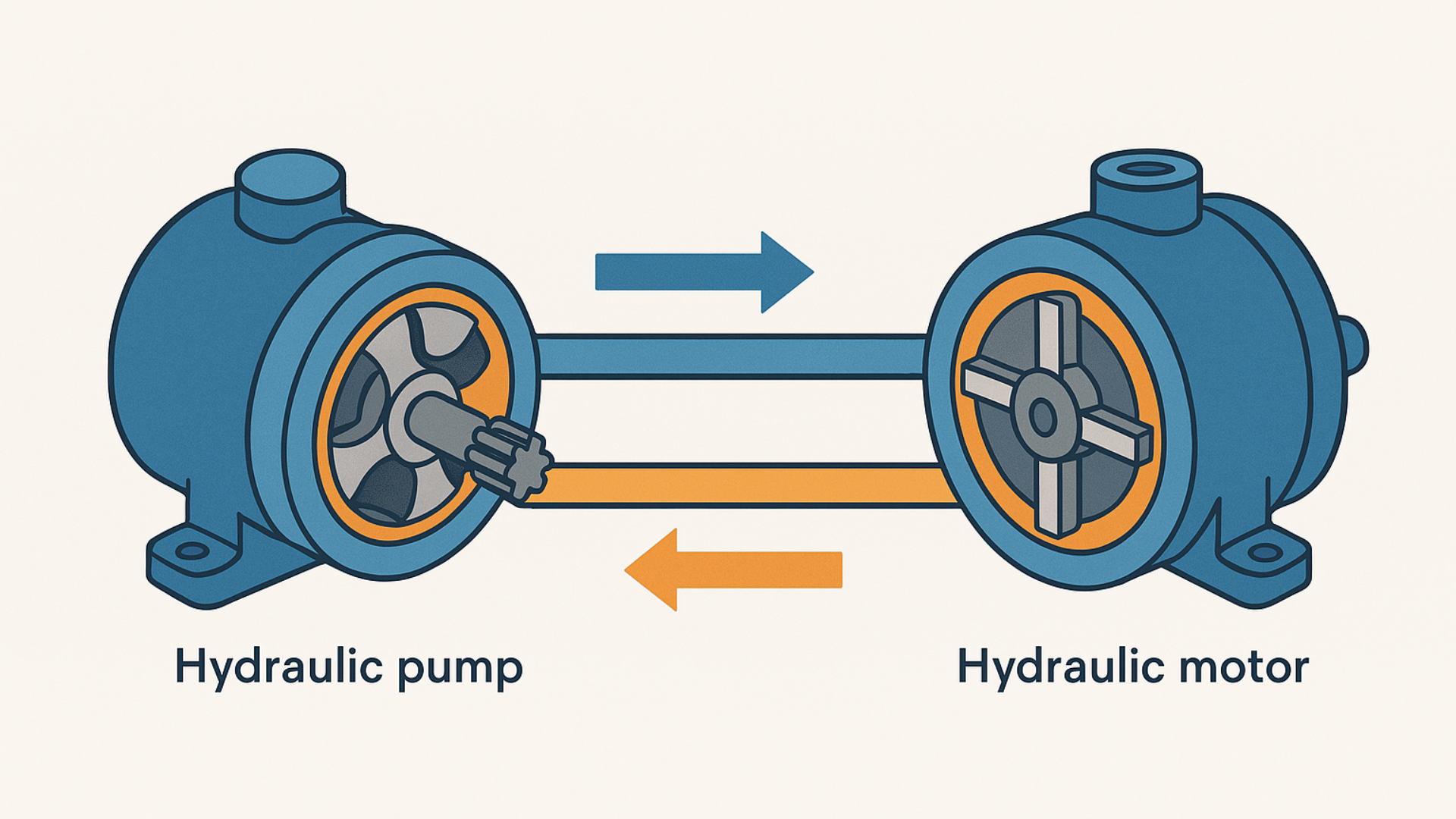

Hydraulic pumps and motors work like a push and pull pair. One pushes oil. The other moves with it. But how they do it tells us why most tools break or run well.

Hydraulic Pumps suck oil from the tank. Then they push it hard into pipes. This oil now has force. This force needs a home. It flows to the hydraulic motor. Here, the motor takes the oil and spins. This spin turns into move, press, or lift.

There are three main types of pumps:

- Gear Pumps – Low cost, easy to use.

- Vane Pumps – Good for mid-load tools.

- Piston Pumps – Best for high force, big size jobs.

Most large presses or mix tools in a cement plant need piston pumps. They last long and take heat well.

Now comes the motor. Motors too have types:

- Gear Motors – Simple tools like fans.

- Vane Motors – Light load arms or belts.

- Piston Motors – Big presses and mill tools.

What links them is oil. If pump speed is low, the motor slows. If pressure drops, the motor shakes. So if one part fails, both suffer. You must match the pump and motor. Else, the tool will heat, leak, or shake.

That is why most makers now sell hydraulic pumps for sale as full kits with matched motors. They know that mismatch kills flow.

How to Match the Right Pump and Motor: Use This Table

If you buy parts on your own, you must match size, speed, and flow. One wrong step, and the tool won’t run. Use this chart to help:

|

Machine Type |

Best Pump |

Best Motor |

Flow Range |

Speed Range |

|

Cement Batch Plant |

Piston Pump |

Piston Motor |

40–120 L/min |

500–1000 RPM |

|

Plastic Mould Machine |

Vane Pump |

Gear Motor |

30–80 L/min |

1000–1500 RPM |

|

Steel Mill Conveyor |

Gear Pump |

Vane Motor |

60–90 L/min |

700–1100 RPM |

|

Tool Press in Machine Shop |

Piston Pump |

Piston Motor |

90–150 L/min |

400–900 RPM |

|

Road Crane |

Gear Pump |

Gear Motor |

50–70 L/min |

800–1300 RPM |

Tip: When you pick a hydraulic pump motor combo, ask your seller for real specs. Never guess.

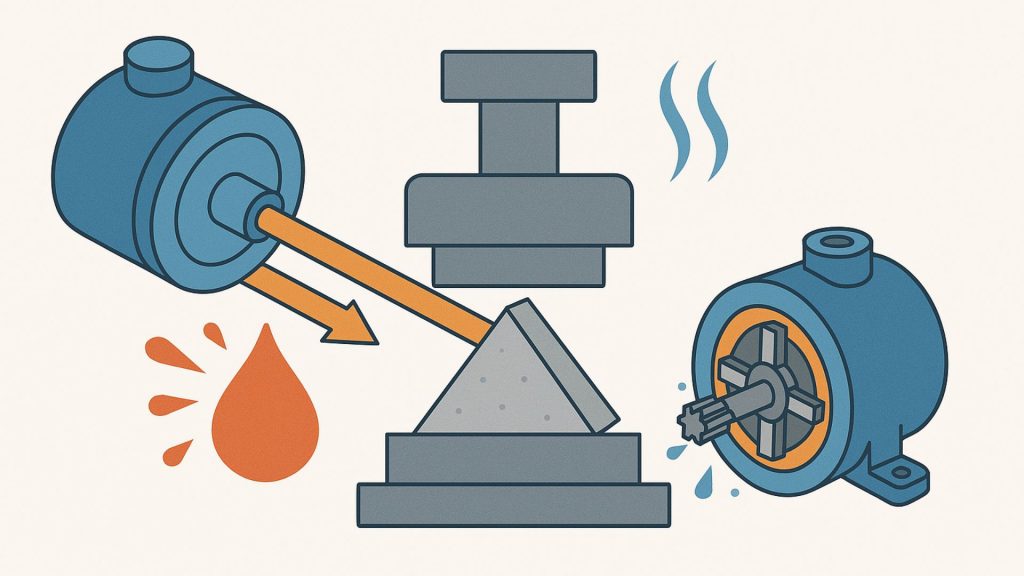

Why Bad Pairing Wastes Oil and Breaks Tools

You might think all oil tools work the same. But that is false. Bad fit causes heat, leak, and lost power. Think of a cement press. If oil flow is low, the head won’t lift. If flow is high, seals burst. This is what we mean by poor match.

This is what we see:

- Heat Rise: Oil gets hot. Pump makes more noise.

- Seal Leak: Motor seals crack fast.

- Slow Speed: Arms take too long to move.

- Load Drop: Mid task, the press stops.

- High Cost: Fuel and part bills go up fast.

If you face such issues, check the pump size, motor load, pipe width, and oil type. Most plant heads now run a test log once per month. They match oil flow to tool load. This way, they fix flaws fast.

New Ways to Test and Fix Hydraulic Systems

In 2025, most top plants use smart checks. No more guesswork. They use tools like:

- Flow Meters

- Thermal Cameras

- Pressure Gauges

- Motor Speed Monitors

These show if the pump gives low flow or if the motor draws too much torque. You can spot a bad valve or blocked pipe this way.

Also, try these steps:

- Bleed the system once each month.

- Check seals every 2 weeks.

- Flush oil after 500 run hours.

- Clean filters on time.

- Use the right oil for the heat range.

This small plan saves big bucks. And if you are still not sure, try our hydraulic pumps for sale—they come with full fit kits.

How THM Huade Pumps Stand Out in the Crowd

At THM Huade, we test each hydraulic pump motor pair for real world load. We sell gear, vane, and piston pumps with matched motors for each tool size.

You will get:

- High flow pumps for cement and steel jobs

- Fast shift motors for plastic and mold work

- Low-noise sets for indoor shop tools

- Spare seals and kits in the box

With global ship reach and ISO checks, you can count on us. You don’t just buy a pump—you buy peace.

Conclusion: Use Smart Fit to Pick the Right Hydraulic Pumps and Motors

If you run a plant or build a tool, your choice of hydraulic pumps and motors will make or break your job. One wrong match and your full line could stop.

We say this—use small checks. Use smart tools. Get matched pumps and motor kits. And trust those who test and build with care.

At THM Huade, we give you kits, not parts. We help you save time, cut oil waste, and keep your press or mold live.

Check our site to see the types of pumps we sell and ask for a free match check. Let us help you choose what fits best. We care for your tools, just like you do.

FAQs

Can I use car oil in hydraulic pumps?

No. Car oil breaks fast in heat. It lacks the grip and seal strength hydraulic oil needs. Always use the oil grade your pump asks for.

No. Car oil breaks fast in heat. It lacks the grip and seal strength hydraulic oil needs. Always use the oil grade your pump asks for.

This may be due to air in oil, low flow from the pump, or heat block in the valve. A flow check or flush may fix it.

Are all hydraulic pumps loud?

Not true. Gear pumps make more noise. Vane and piston pumps can be near silent if fit well. Noise may also mean air or heat issues.

How long do hydraulic pumps last?

With good oil, clean pipes, and no overload, they last five to ten years. Cheap oil or clogged lines cut life fast.