Choosing the right component is key when using mobile equipment. The use of hydraulic power packs in mobile equipment offers clear, measurable benefits. A quality hydraulic power pack can boost performance in hydraulic systems. This is true for mobile equipment used in construction and agriculture. Right from the start, these systems deliver higher efficiency, reliability, and control.

Why Choose Hydraulic Power Packs for Mobile Equipment?

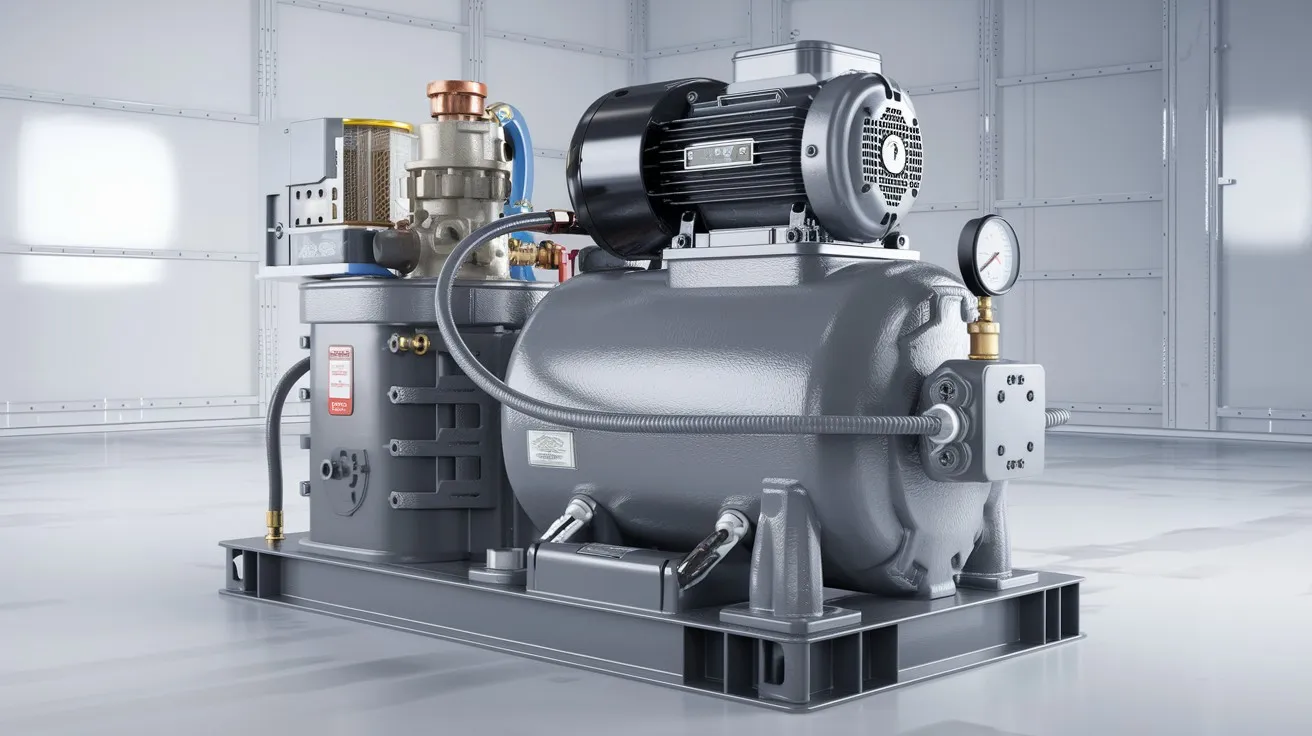

Using hydraulic power packs gives mobile equipment small, self-contained units. These units provide pressurized fluid power wherever needed. Hydraulic power pack systems provide high power density. They use energy in a way that minimizes waste. This makes them better than pneumatic or purely mechanical solutions. For mobile equipment, this means less downtime, more flexibility, and better output.

What are the Key Benefits of Hydraulic Power Packs?

1. Compact Design & Mobility

A key benefit of hydraulic power packs is their compact design. This feature makes them perfect for mobile use. For example, some 12 V systems provide enough power for field equipment. They stay lightweight and portable. This portability allows crews to use mobile equipment in remote or confined spaces. They don’t need big infrastructure to do this.

2. Exceptional Efficiency

Hydraulic power packs change electrical or mechanical energy into effective hydraulic power. They achieve this with greater efficiency than pneumatic options. Mobile equipment uses less energy, reducing costs and supporting environmental goals.

3. Precision Control & Better Performance

Hydraulic power packs offer refined control over pressure and flow. In mobile equipment, this control helps make hydraulic functions smoother. This includes actions like lifting, tilting, and rotating. That precision results in safer, faster, and more reliable performance at the job site.

4. Durability & Reliability in Harsh Conditions

Mobile equipment often faces rugged outdoor environments. Engineers build hydraulic power packs to handle tough conditions. They can manage high pressure, heavy use, and dirty environments. That means fewer unexpected failures and less maintenance downtime.

5. Versatility Across Applications

You can find a hydraulic power pack for sale to power a construction vehicle, farm tool, or mobile factory. These systems adapt with ease. They integrate into hydraulic systems for mobile equipment across industries. With proper specifications, one pack can cover many tasks.

6. Cost-Effectiveness Over Time

A hydraulic power pack may cost more upfront than simpler options. But it offers significant savings over time. Lower energy use, reduced maintenance, and extended lifespan all add up. For mobile equipment operators in the U.S.A., this means better return on investment.

How to Choose the Right Hydraulic Power Pack for Mobile Equipment?

When searching for a hydraulic power pack for mobile equipment, keep these key points in mind:

- Adjust the flow rate and pressure to meet your mobile equipment’s hydraulic needs.

- Choose the right power source: Electric, diesel, or PTO (power take-off). This depends on the equipment’s operating location.

- Consider portability and installation: Ensure space, mounting, and transport fit mobile equipment constraints.

- Check maintenance accessibility: Filters, fluid checks, and controls must be reachable.

- Consider future growth: A larger pack can manage extra attachments or tasks later.

How to Integrate Hydraulic Power Packs into Mobile Equipment Workflows?

For mobile equipment, hydraulic power packs should fit smoothly into hydraulic systems. Install the unit near the hydraulic actuators. This reduces hose length and pressure loss. Then, set up control valves and relief systems for safety and precision. The right pack works with cylinders and motors. It changes energy into motion while wasting very little. Regular maintenance is key to the hydraulic power pack. It ensures good performance, especially for field mobile equipment.

Conclusion

In mobile equipment applications across the USA, hydraulic power packs deliver real value. They boost hydraulic systems in mobile equipment. This enhances efficiency, precision, durability, and flexibility. Choosing the right hydraulic power pack is key. This is true in construction, agriculture, and industrial work. Integrating it properly establishes a solid foundation for your success. Embrace this technology. Your mobile equipment will perform better, run smoother, and be more reliable.

Choose the right pack. Install it following the guidelines. Maintain it with precision. This way, you’ll enjoy all the benefits of hydraulic power packs in mobile equipment.

Power your performance with THM Huade Hydraulic Power Packs, engineered for precision, durability, and reliability. Contact us today to explore our hydraulic power pack for sale and discover how our hydraulic systems for mobile equipment can elevate your operation to the next level.

Common FAQs About Hydraulic Power Packs for Mobile Equipment

Q2: Why are hydraulic power packs ideal for mobile equipment?

Because they offer compact size, high power density, and robust performance, these traits make them well-suited for use with mobile equipment on job sites.

Q3: Can I find a hydraulic power pack for sale that fits my mobile equipment?

Yes, many suppliers in the USA provide hydraulic power packs designed for mobile use. Make sure the pack fits your flow, pressure, power source, and equipment limits.

Q5: What are the risks of choosing the wrong power pack?

A small hydraulic power pack can lead to slower performance, overheating, or failure. If you have an oversized item, you may waste energy and incur unnecessary costs.