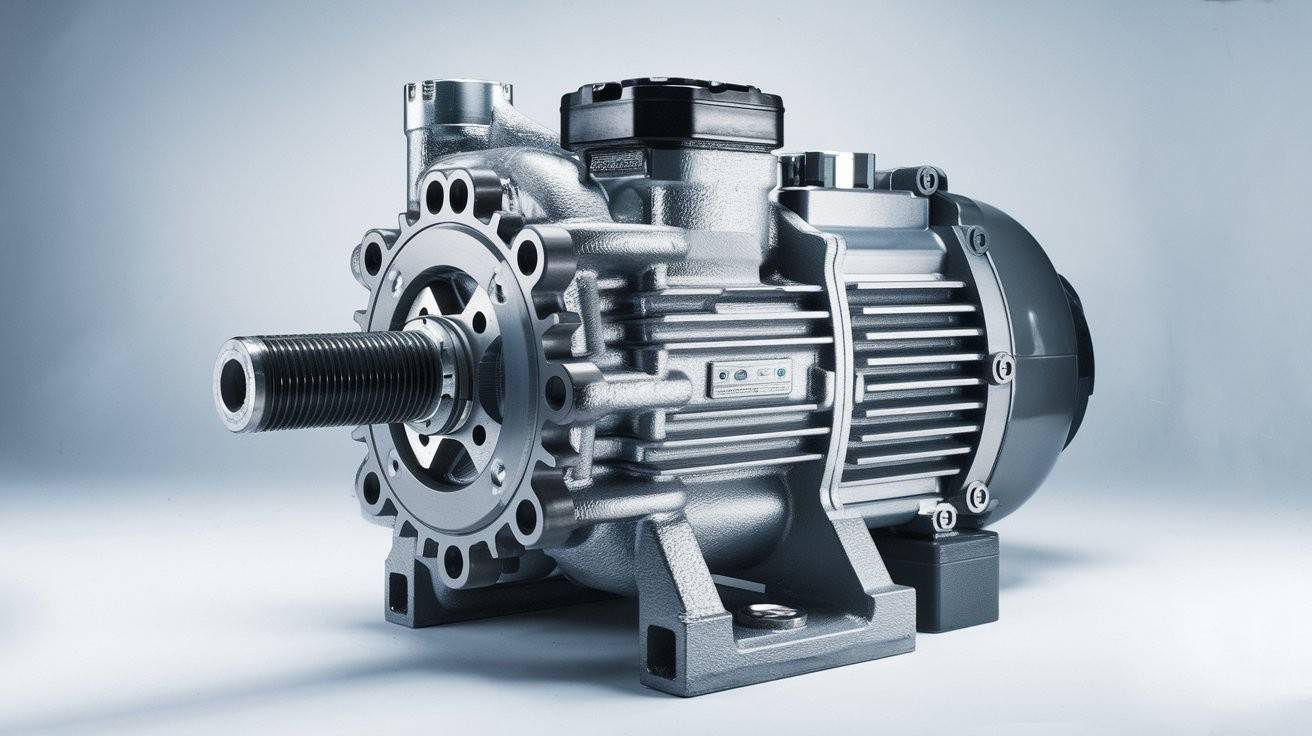

When it comes to hydraulic systems, the hydraulic fluid pump plays a central role. It works alongside the hydraulic pump and the hydraulic motor pump to maintain system pressure and flow. Knowing how a hydraulic fluid pump works is key for anyone in heavy equipment, manufacturing, or mobile hydraulics. In this article, we’ll dive into why the hydraulic fluid pump is essential, how it works, and how it keeps your pressure systems operating smoothly.

How the Hydraulic Fluid Pump Drives Pressure Systems

The hydraulic fluid pump is the device that initiates fluid movement within a hydraulic circuit. It pulls fluid from a reservoir and pushes it into the system. But it is important to note that a hydraulic pump does not create pressure. Instead, pressure comes from the resistance to flow within the system.

When fluid moves, the system’s valves, tubing, and actuators, like cylinders or motors, create resistance. The hydraulic fluid pump must supply the flow required to overcome that resistance. When flow meets resistance, pressure builds, and the system performs work.

In effect, the hydraulic fluid pump is a flow generator. The hydraulic pump and motor work together in the circuit. They turn flow into motion or force.

Key Functions of the Hydraulic Fluid Pump in Pressure Systems

1. Flow Generation

The hydraulic fluid pump provides a continuous flow of fluid. This flow is the basis of force generation in a hydraulic system. Without flow, no one does useful work.

2. Enabling Pressure Build-up

The hydraulic fluid pump creates pressure because the fluid meets resistance from valves, hoses, and loads. That pressure then drives actuators and motors.

3. Delivering Energy to Hydraulic Motors

In systems that use a hydraulic motor pump, the flow from the hydraulic fluid pump drives the motor. The motor converts the hydraulic energy back into mechanical energy for rotary motion.

4. Supporting System Stability and Performance

Without the hydraulic fluid pump maintaining proper flow, the system pressure may drop. This can lead to slower actuation, underperformance, or even system failure.

What are the Types of Hydraulic Pumps You’ll Encounter?

There are different types of hydraulic pumps. Each one suits various pressure systems and applications:

- Gear pumps – simple design, steady flow, cost-effective.

- Vane pumps – moderate pressure, quiet operation.

- Piston pumps (axial or radial), high-pressure, are often used in demanding heavy-duty environments.

When choosing a hydraulic fluid pump, it’s important to match the flow rate, pressure rating, and system resistance. In other words, you must match the pump to your application’s demands.

Why System Pressure Depends on More Than Just the Pump?

The hydraulic fluid pump is important, but system pressure also relies on other components and design factors:

- Hose and tube sizing: Smaller diameters or longer lengths increase resistance. This causes a greater pressure drop.

- Valves, filters, and actuators: These add resistance and influence the effective pressure for work.

- Load and actuator size: The area of a cylinder affects the pressure required for a given force.

- System Maintenance: Air in the lines, fluid degradation, or leaks can lower performance and pressure.

The hydraulic fluid pump provides flow, but getting the right system pressure takes teamwork. It involves the pump, circuit design, and load matching.

How to Ensure Your Hydraulic Fluid Pump Performs Well?

Here are practical steps to ensure the hydraulic fluid pump remains essential and effective:

- Select a pump with appropriate flow capacity and pressure rating for your load.

- Ensure proper hose and tubing diameter, with minimal unnecessary bends or restrictions.

- Maintain good fluid quality: clean, with proper viscosity and free of air bubbles.

- Use pressure relief valves and other control elements to keep system pressure within safe limits.

- Check system pressure and flow. Low pressure might show problems in other areas, not with the pump.

What is the Importance of the Hydraulic Motor Pump and Its Relationship

The “hydraulic motor pump” focuses on a key part: in many hydraulic systems, the hydraulic fluid pump provides flow. The hydraulic motor pump (or hydraulic motor) converts fluid energy into motion or torque.

In effect, the hydraulic fluid pump and hydraulic motor pump form a sequence:

- The hydraulic fluid pump pushes fluid into the system.

- The fluid passes through valves and actuators and then drives the hydraulic motor pump or the motor/actuator.

- The motor pump converts fluid pressure and flow into mechanical rotation or linear motion.

This shows that the motor pump works well due to the upstream flow and pressure. Even though it is downstream, the hydraulic fluid pump supports its effectiveness.

Conclusion

The hydraulic fluid pump is crucial for pressure systems. It provides the flow required to generate pressure and perform work. It’s the key driver of hydraulic power. To use the hydraulic pump well, focus on system design, resistance, actuator size, and flow path. The hydraulic motor pump and other parts make hydraulic systems work well and powerfully.

To keep your hydraulic pressure system running well, choose the right hydraulic fluid pump. Also, make sure the downstream system works with it. This will help avoid surprises and maintain peak efficiency.

Ready to boost your system performance?

Reach out to THM Huade today to secure your precision-engineered hydraulic pump or motor and experience unmatched pressure system power.

FAQs

Q2. Does the hydraulic fluid pump generate pressure directly?

A. No, the pump generates flow. Pressure results from the resistance to that flow in the circuit.

Q3. How do I pick the right hydraulic pump for my system?

A. Consider the required flow rate, maximum operating pressure, fluid type, and the load characteristics. Also account for tubing size, system resistance, valve settings, and actuator requirements.

Q4. What role does the hydraulic motor pump play compared to the hydraulic fluid pump?

A. The hydraulic motor pump (or hydraulic motor) takes fluid from the hydraulic fluid pump. It then changes that fluid into mechanical motion. The hydraulic fluid pump provides the “fuel.” The motor pump uses it for mechanical output.

Q5. What are common maintenance issues affecting hydraulic fluid pumps?

A. Issues can include air or foam in the fluid, worn gears and pistons, leaks, the wrong fluid thickness, and hoses that don’t fit properly. These can lead to excessive backpressure or poor flow.