Efficiency and sustainability are the driving factors in industrial and mobile equipment. The mobile and electrical industries are becoming smarter and seeking cleaner alternatives to traditional systems. One of the standard developments is the adoption of electric hydraulic pumps.

An electric hydraulic pump is known for its power & mobility. It is well-designed to deliver precise energy and efficient performance, which makes it a cornerstone in mobile hydraulic solutions. Electric hydraulic pumps meet the demands of modern machinery, offering better control, reduced emissions, and seamless integration with digital platforms. In this blog, we’ll learn about electric hydraulic pumps and the benefits that are making them popular these days. So let’s get started.

Understanding Electric Hydraulic Pumps

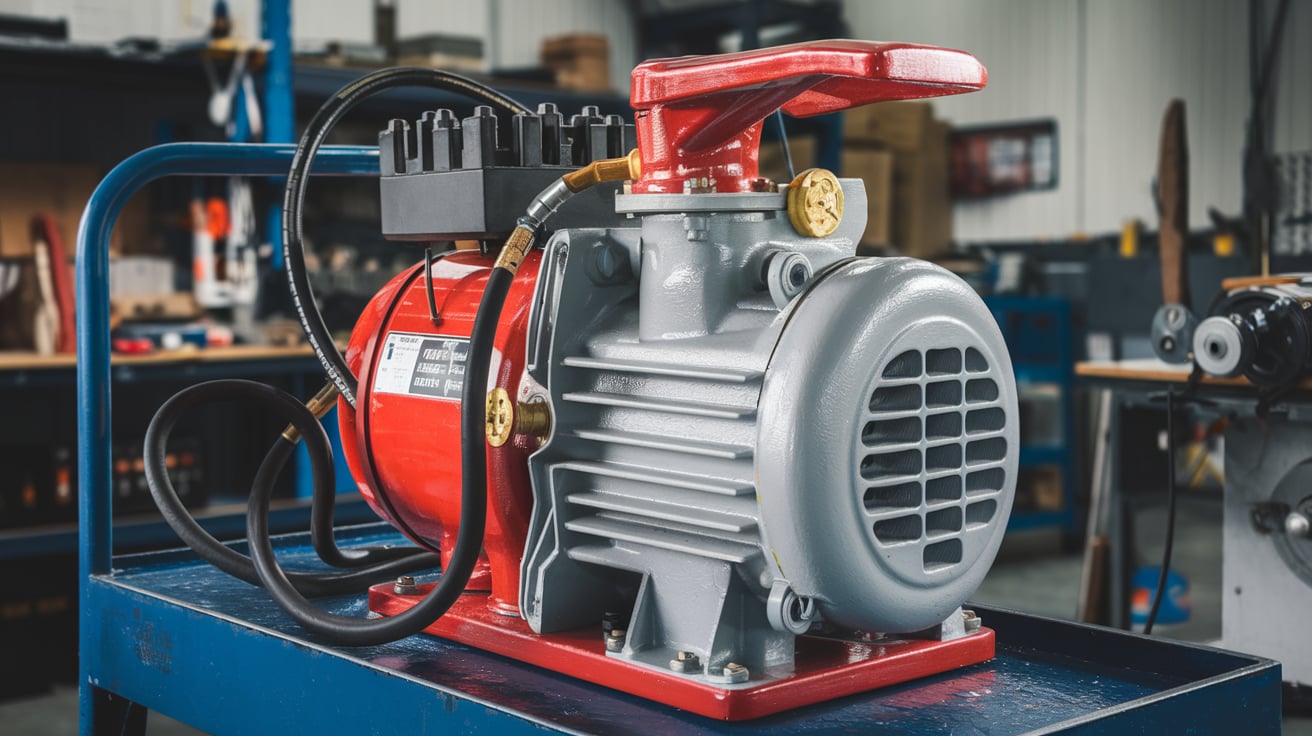

It is a device that converts electrical energy into hydraulic power with high efficiency. This device consists of two major components: the electric motor and the hydraulic pump. The electric motor powers the pump and puts pressure on the hydraulic fluid, and then this fluid flows through the system to perform mechanical work.

Electrical hydraulic pumps are known for their efficiency, reliability, and compact design, which makes them ideal for operations that require precision and clean energy use. These types of hydraulic pumps play an important role in the power & mobility sectors, where lightweight and repo equipment are essential.

Hydraulic pumps are an important component of mobile hydraulic solutions and are widely used in a variety of industries such as construction, material handling, aerospace, and manufacturing for their versatility and easy integration properties into both stationary and mobile platforms.

Electrical hydraulic pumps play an important role in delivering power & mobility, which is the core of modern industrial operation. Their versatility makes them the best choice for mobile hydraulic services in different industries. Let’s take a look at some of the applications of electrical hydraulic pumps in the industry:

- Manufacturing and powering production machinery

- Construction and operation of heavy equipment like cranes, lifts, providing power & mobility on site.

- In the automotive industry, forklift and repair equipment require mobile hydraulic solutions for efficiency.

- In the aerospace industry, for aircraft maintenance and testing.

- In the marines, mobile hydraulic solutions are used for the smooth operation of the steering system and deck equipment.

- The agriculture industry in farm machinery and irrigation systems requires increased power & mobility.

- For evacuation and material handling equipment in the mining industry.

The Key Benefits Of Electrical Hydraulic Pumps Are Driving The Popularity

Industries are moving towards smarter, cleaner, and more reliable technologies, and the electrical hydraulic pump has become a key solution. This well-designed hydraulic pump offers evolving power and mobility across various sectors, providing significant advantages in terms of efficiency, noise reduction, and sustainability. Here are some of the major reasons why electrical hydraulic pumps are gaining popularity over traditional combustion-driven systems.

Enhanced Energy Efficiency

One of the biggest reasons behind the popularity of electric hydraulic pumps is their superior energy efficiency. These energy-efficient devices convert electrical energy into mechanical power with minimal loss, which makes them highly cost-effective in the long run.

Unlike traditional combustion-driven systems, hydraulic electric pumps offer high efficiency levels and consume less energy, which helps businesses reduce operational expenses. This performance makes it a more popular mobile hydraulic solution in industries such as construction, agriculture, and manufacturing.

Eco-Friendly Operations

Reducing carbon emissions is a necessity of the modern world. In comparison to traditional systems, electric hydraulic pumps are a better option as they eliminate harmful pollutants and greenhouse gas emissions. By integrating electric hydraulic systems with their operations, companies can meet strict environmental regulations while also lowering their carbon footprint.

Reduced Noise Levels

Noise pollution is a serious issue in many workplaces, especially in urban environments. Unlike traditional combustion systems, electrically driven hydraulic systems operate with less noise, creating a safer and more comfortable work environment. Companies are transitioning to low-noise electrical hydraulic pumps, as they enhance employee well-being and ensure compliance with occupational safety standards.

Better Accuracy And Stability

An electrical hydraulic pump ensures control over pressure and flow, enabling accurate and stable machine movements in the aerospace, motorsport, and robotic industries. This level of control makes hydraulic electric pumps one of the popular choices for high-precision applications.

Lower Maintenance Needs

A traditional combustion engine requires regular maintenance, including oil changes, fuel filter replacements, and engine servicing. However, electrical hydraulic pumps are designed with fewer moving parts, which minimizes the chance of mechanical failure. This simple design also ensures lower maintenance costs and a longer lifespan, making them reliable and long-term options for industrial use.

Conclusion

With the growth of industries, the demand for smarter and more efficient systems, such as electrical hydraulic pumps, is increasing rapidly. These pumps enhance their power and mobility, supporting a wide range of mobile hydraulic solutions across various sectors, including construction, agriculture, aerospace, and many others. The aforementioned benefits of an electrical hydraulic pump, including energy efficiency, low maintenance, and eco-friendly performance, make it a reliable and popular choice in this industry.

Whether you are planning to upgrade the existing system or implement a new solution, get in touch with THM Huade today for the best electric hydraulic technology that is the right choice for long-term operational success and sustainability.

Frequently Asked Questions

What are the advantages of an electric hydraulic pump?

Electric hydraulic pumps of high-powered density, low maintenance requirements, location and usage, versatility, clean energy, and general costs.

What is the working principle of an electro-hydraulic system?

Electrohydraulic systems consist of several components, such as:

Electric motor: which converts electrical energy to mechanical energy

Pump: which converts mechanical energy into hydraulic energy

Curator: which converts back hydraulic energy into mechanical energy.

How does an electric hydraulic pump work?

The hydraulic pump converts the mechanical force into fluid energy. This fluid energy takes the form of oil flow. After this, the hydraulic motor takes the fluid energy that the pump created and converts it into mechanical energy.