The High Torque Planetary Gearbox has become one of the pillars of power transmission technology in the current fast-changing industrial environment. This gearbox system is famous with its compact design, high torque output, and smooth motion control that is applied in a broad range of industries. Regardless of whether you are dealing with automation, robotics or heavy machinery, Planetary Gearbox is a game changer in terms of efficiency and durability.

How Planetary Gearbox Works

Planetary Gear System is composed of:

- Central sun gear

- Planet gears around

- A peripheral gear

- A planet gears carrier of which it is the holder of the planet

The system is also well balanced in loading, and it can transfer more torque in a compact planetary gearbox design. This is why it is applied in programs where space and efficiency are of importance.

Important Advantages of Planetary Gear Mechanism

The following are the best benefits of Planetary Gear Reducer usage:

- Large torque to size ratio

- Silent and smooth running

- Improved load balance

- Higher efficiency (up to 98%)

- Very tough to do continuous-duty work

- Suitable to automation & robotics

The advantages render it ideal in precision planetary gearbox applications where accuracy and reliability are not an option.

Top Industries & Applications Using Planetary Gearbox

1. Industrial Automation

- Conveyor belts

- CNC machines

- Factory robotics

- Packaging equipment

Servo Motor applications with Planetary Gearbox are successful here due to fine speed and torque control.

2. Robotics

- Humanoid robots

- Autonomous mobile robots (AMRs)

- SCARA robots & Delta robots

Precision Planetary Gearbox is used to make precise and smooth movements of compact robotic system.

3. Automotive Sector

- Electric cars (EVs)

- Differential systems

- Power steering assemblies

The planetary gear reducer makes it possible to have high torque in a small volume, which is critical to the modern EV drivetrain.

4. Aerospace and Defense

- Wing and aircraft flaps

- Radar positioning

- Satellite communication networks

Light but robust gearboxes are needed in the Industrial Gearbox Solutions in this field. This is where the design of compact planetary gearbox shines.

5. Medical Equipment

- MRI scanners

- Surgical robots

- Automation systems in laboratories

The planetary gear system is used in sensitive environments as it has low noise and high precision.

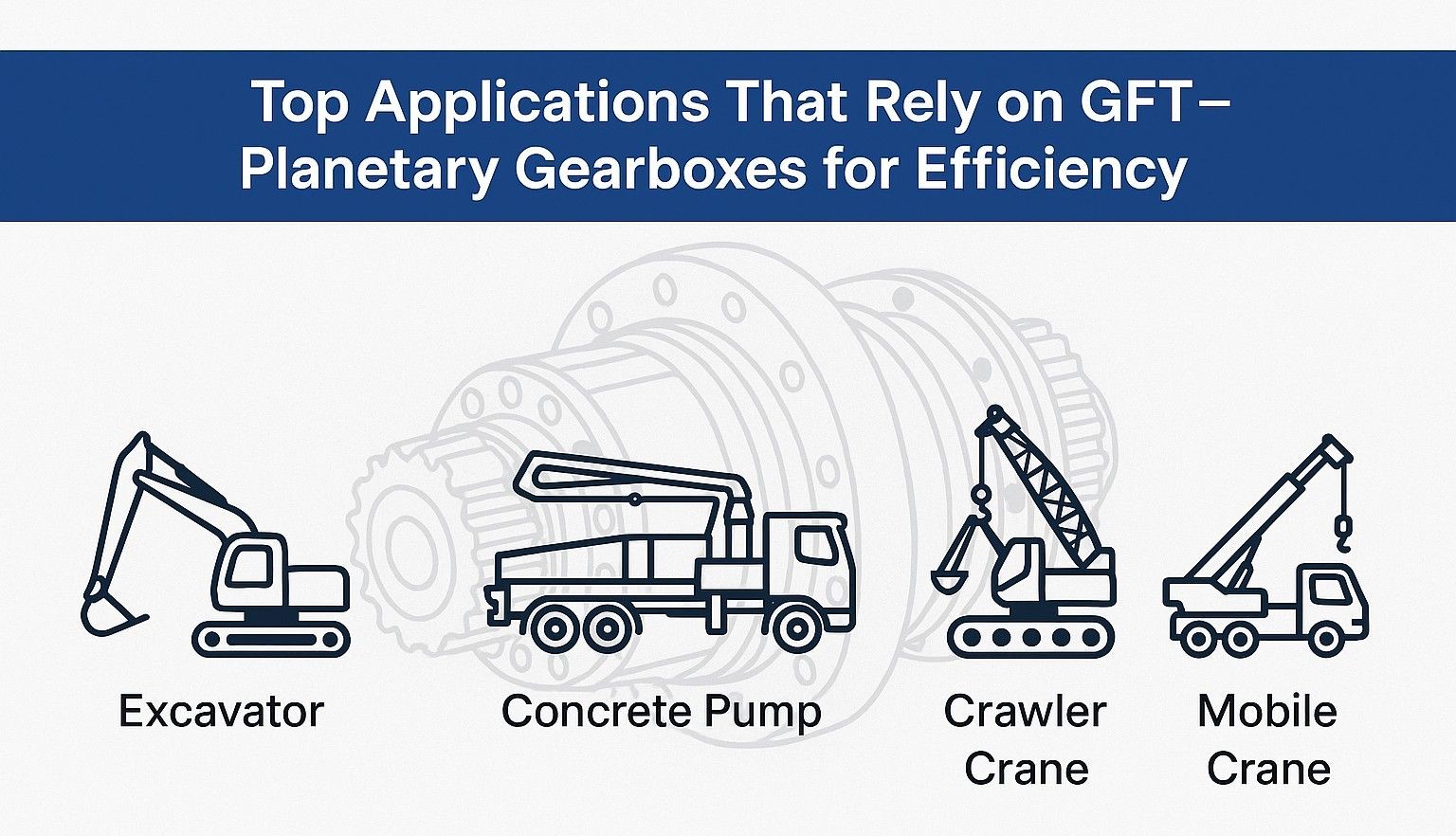

6. Construction and Heavy Machinery

- Earthmovers

- Excavators

- Cranes

- Mixers

High Torque Planetary Gearbox is essential in this case, which provides the best load carrying capacity in harsh conditions.

7. Printing and Textile Machinery

- Web tension systems

- Precision rollers

- Embroidery machines

Servo Motor Planetary Gearbox allows synchronous operations at high speed, very important in textile and printing industries.

8. Renewable Energy and Wind Turbines

- Blade positioning

- Generator systems

Planetary gear reducer systems assist in effective conversion of energy by ensuring that the RPM and torque is at optimum.

9. Marine and Offshore Equipment

- Winches

- Propeller drives

- Drilling machinery

The planetary gear systems are suitable to such demanding applications due to their rugged construction and torque capacity.

10. Food Processing and Packaging

- Bottle capping machines

- Conveyor rollers

- Slicing systems

Where space is limited and food-grade requirements are needed, compact planetary gearbox design is a clean and efficient solution.

Common GFT models- Planetary Gearbox

THM Huade has a vast selection of GFT – Planetary Gearbox models that are compact and high-torque and used in numerous industries. Some of the trusted models which are commonly used in machinery, mobile equipment and automation are as follows:

TH-GFW5190F

TH-GFT8190F

TH-GFT220

TH-GFT160

TH-GFT110

TH-GFT80

TH-GFT60

TH-GFT50

TH-GFT36

TH-GFT17

GFT 0013 W2 2000/1

GFT 0013 W2 2000/2

GFT 0013 W2 4000/1

GFT 0013 W2 4000/2

GFT 0017 W2 2000

GFT 0017 W2 4000

GFT 0017 W3 2000

GFT 0017 W3 4000

GFT 0024 W3 2000

GFT 0024 W3 4000

GFT 0026 W2 2000/1

GFT 0026 W2 2000/2

GFT 0026 W2 4000/1

GFT 0026 W2 4000/2

GFT 0026 W2 6000/1

GFT 0026 W2 6000/2

The models have a reputation of high torque density, durability, and precision, and are used in demanding industrial applications such as gearbox solutions.

Tips for Choosing the Right Planetary Gearbox

- Torque and speed requirements Define

- Select proper gear ratios

- Precision and backlash Consider

- Lubrication and sealing to last long

- Pair it with your servo motor type

A planetary gearbox that perfectly fits servo motor offers smooth operation, which is energy efficient.

Conclusion: The Future is Powered by Planetary Gear Systems

The High Torque Planetary Gearbox is transforming the power transmission in industries, whether it is in the field of robotics or renewable energy. The planetary gearbox solutions are rapidly increasing in demand, as the servo motor-driven systems and smart automation become more common.

THM Huade provides state-of-the-art industrial gearbox technology that incorporates the most innovative planetary gear mechanism design-in durability, efficiency, and compact operation in all industries.

FAQ’s

Q: How to calculate planetary gearbox ratio?

Gear ratio =:

A fixed carrier system would be 1 + (Ring Gear Teeth / Sun Gear Teeth).

Q: Does CVT use planetary gears?

Conventional CVTs do not but more advanced variants such as ECVTs and hybrid systems do employ planetary gear systems to provide more control.

Q: Which is better CVT or ECVT?

ECVT tends to be more suitable to hybrid cars, where the electric motor control is coupled with planetary gear mechanism to provide a smooth transition.

Q: What are the three types of planetary gears?

The three of them are:

Simple planetary gearset, compound planetary gearset and stepped planetary gearset.

Q: How to work a planetary gearbox?

The principle behind a planetary gearbox is that planet gears are rotated around a center sun gear and the torque is transferred to the output shaft via a carrier.