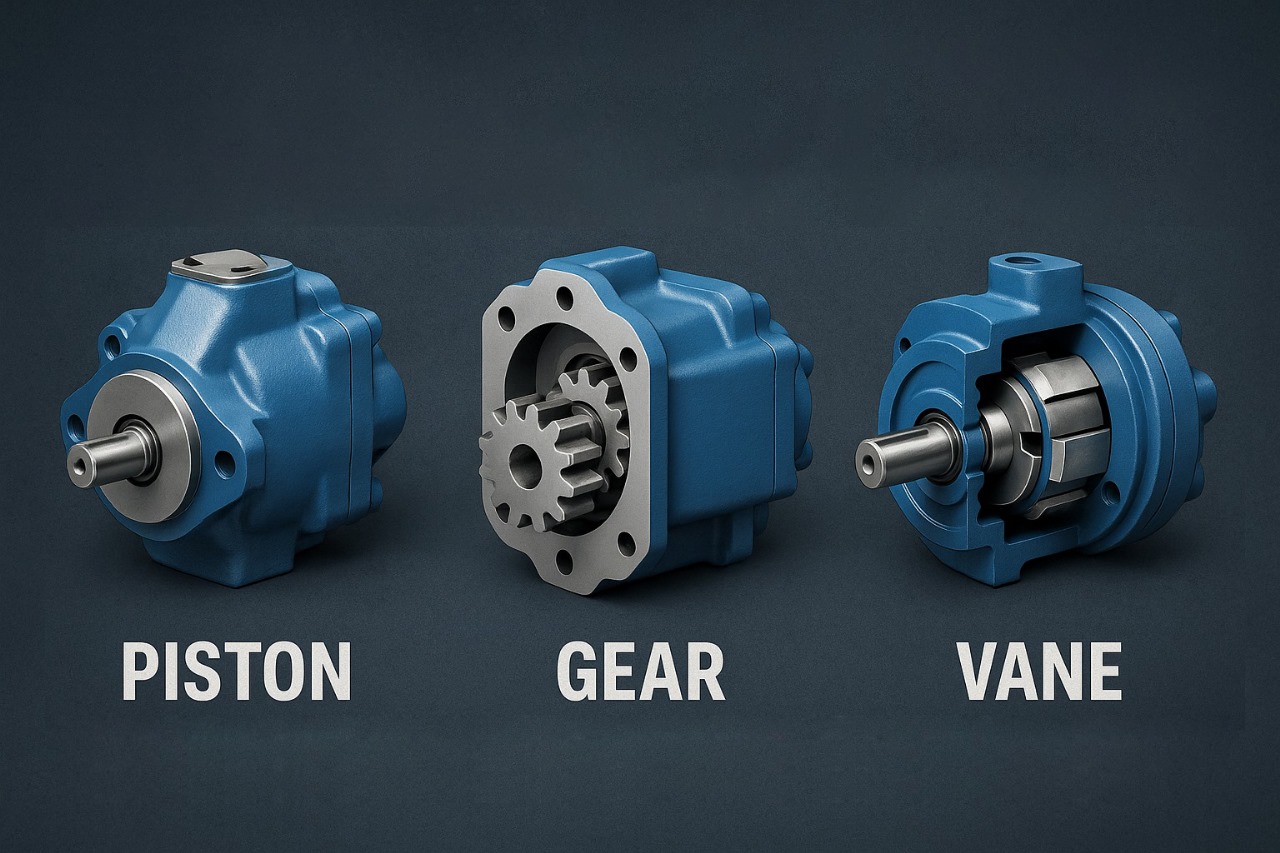

In selecting the appropriate hydraulic piston pump to meet your industrial requirements, you need to consider the advantages and disadvantages of three common types, namely piston pumps, gear pumps and vane pumps. Hydraulic pump systems are different and possess specific features, pressure, and optimum application. Be it high pressure hydraulic pump to accomplish heavy-duty job or hydraulic gear pump to perform in a steady, reliable manner, this guide will assist you in making an informed choice.

What are Hydraulic Pumps and Why are they important?

A hydraulic pump system transforms the mechanical energy to the hydraulic energy. Such systems are used in manufacturing, agriculture, construction and others.

Main Types of Hydraulic Pumps:

1. Hydraulic Piston Pump The Power Performer

Best Use: High-stress industrial, mobile and heavy-duty equipment.

Features:

- Provides high pressure to 700 bar

- Able to have variable and fixed displacement

- Very energy-efficient and economical

- Extended service life

Applications:

- Injection molding machines

- Marine hydraulics

- Mining operations

- Aerospace and defense

Advantages:

- High performance at different loads

- It is ideal as high pressure piston pump

- Long lasting to be used continuously

- Very sensitive and dependable

THM – A4VG – Variable Displacement Axial Piston Pump – Model Codes:

A4VG125DA2D2/32R-NSF02F021PP, A4VG125DA2D8/32R-NSF02F001BP, A4VG125EP4D1/32R-NZF02F001DP-S, A4VG125EP4D1/32R-NZF02F001SP, A4VG125EP4DM1/32R-NSF02F001DP, A4VG125EP4DM1/32R-NZF02F001DH, A4VG125EP4DT1/32L-NZF02F021SH, A4VG125EP4DT1/32R-NTF02F071BP, A4VG175EP2DPR00/40MRNE4T11F0000AD00-0, A4VG180EP4DM1/32R-NZD02F021SH-S, A4VG40EP4D1/32R-NZC02F005DH, A4VG40EP4DM1/32R-NSC02F005DP, A4VG40HD3D1/32R-NSC02F003D, A4VG56EP4DM1/32R-NZC02F006DP, A4VG56HD3DM1/32L-NZC02F015S, A4VG56HD3DM1/32R-NSC02F005S, A4VG71DA1D3L/32R-NZF02F041FP, A4VG71EP4D1/32R-NZF02F001DH, A4VG71EP4DM1/32R-NSF02F001DP, A4VG90EP4D1/32R-NZF02F001SP, A4VG90EP4DT1/32R-NZF02F021SP-S, A4VG90EZ2DMT1/32R-NAF02F041DQ, A4VG90EZ2DMT1/32R+A10VO45DFR1/31+AZPG-22, A4VG90HD3D1/32L-NZF02F021D, A4VG90HWDM1/32R-NZF02F001S-S, AA4VG56EP4DT1/32R-NSC52F005SH-S, AA4VG56HD3DT1/32R-NSC52F005S-S, AA4VG90HWD1/32L-NSF52F001D

2. Hydraulic Gear Pump – The Reliable Workhorse

Best For: Low to medium pressure, constant flow applications.

Features:

- Easy design and less moving parts

- Up to 3000 psi (207 bar) pressure

- Low maintenance and economical

Applications:

- Construction equipment

- Agricultural machinery

- Material handling

Advantages:

- Installation and maintenance is easy

- Affordable startup capital cost

- Small size suitable to smaller machines

Note: Most manufacturers of gear pumps provide customized designs to fit various applications.

THM – IGP05 Series – Internal Gear Pump – Model Codes:

THM IGP(H)-33-160-160-02T/R-PVS, THM IGP(H)2-32-02T/R-PVS, THM IGP(H)2-32-02T/R-PVS-L-36, THM IGP(H)2-40-02T/L-SVS, THM IGP(H)2-40-02T/R-PVS (T040010174), THM IGP(H)2-40-02T/R-SVS, THM IGP(H)2-50-02T/L-SVS, THM IGP(H)2-50-02T/R-PVS (T050010184), THM IGP(H)2-50-02T/R-SVS, THM IGP(H)2-63-02T/L-SVS, THM IGP(H)2-63-02T/R-PVS-(S10), THM IGP(H)2-63-02T/R-SVS, THM IGP(H)3-100-02T/R-PVS (T010010104), THM IGP(H)3-125-02T/R-PVS-(S10), THM IGP(H)3-145-02T/R-PVS, THM IGP(H)3-145-02T/R-PVS-(S10), THM IGP1-10-01T/R-VPC, THM IGP1-13-01T/R-VPC, THM IGP1-13-02T/R-PVS (T013010123), THM IGP1-16-01T/R-VPC, THM IGP1-16-02T/R-PVS (T016010133), THM IGP1-20-01T/R-VPC, THM IGP1-32-01T/R-VPC, THM IGP2-25-01T/R-VPC, THM IGP2-25-02T/L-SVS, THM IGP2-25-02T/R-PVS (T025010154), THM IGP2-32-01T/R-VPC, THM IGP2-32-01T/R-VSC, THM IGP2-32-02 R T/R-PVS-B (BR Equivalent), THM IGP2-32-02T/L-SVS, THM IGP2-32-02T/R-PVS (T032010166), THM IGP2-40-01T/R-VPC, THM IGP2-40-01T/R-VPC-S10, THM IGP2-40-02 R T/R-PVS-B (BR Equivalent), THM IGP2-40-02RT/R-PVS-B, THM IGP2-50-01/R-VPC-L-36, THM IGP2-50-01T/R-VPC, THM IGP2-50-01T/R-VPC-L-36, THM IGP2-50-01T/R-VPC-S10, THM IGP2-50-02 R T/R-PVS-B (BR Equivalent), THM IGP2-50-02T/R-PVS, THM IGP2-63-01/R-VPC-L-36, THM IGP2-63-01T/R-VPC, THM IGP2-63-01T/R-VPC-L-36, THM IGP2-63-01T/R-VPC-S10, THM IGP2-63-02T/R-PVS, THM IGP2-63-02T/R-VPC-S10, THM IGP3-100-01T/R-VPC, THM IGP3-100-02T/R-PVS, THM IGP3-125-01T/R-VPC, THM IGP3-125-02T/R-PVS (T012501105), THM IGP3-160-01T/R-VPC, THM IGP3-160-02T/R-PVS, THM IGP3-80-01T/R-VPC, THM IGP3-80-02T/R-PVS-S10

3. Hydraulic Vane Pump – The Quiet Performer

Best For: Medium pressure, quiet operation environments.

Features:

- Silent and smooth running

- Mid range pressure (up to 210 bar)

- Industrial and mobile compatible

Applications:

- Automobile power steering

- CNC machinery

- Machine tools

Advantages:

- Constant flow and low noise

- Self compensating wear mechanism

- Mid-range system cost-effective

Efficiency and smooth operation are some of the major factors to consider when selecting a rotary vane pump.

THM – T6C – Fixed Displacement Vane Pump – Model Codes:

T6C-020-1R00, T6C-025-1R00, T6C-028-1ROO, T6C-031-1R00, T6C-B17-2L00-B2, T6CB05-2R00B1, T6CB06-2R00B1, T6CB08-2R00B1, PV2R5-270-A-F1C-22R, PV2R5-320-A-F1C-22R, PV2R5-350-A-F1C-22R,VPS-1-20–PR15R/1XT V, VPS-1-25–PR15R/1XT V, VPS-1-32–PR15R/1XT V, VPS-1-40–PR15R/1XT V, VPS-1-50–PR15R/1XT V, VPS-1-64–PR15R/1XT V, VPS-2-100–PR15R/1XT V, VPS-2-110–PR15R/1XT V, VPS-2-125–PR15R/1XT V, VPS-2-145–PR15R/1XT V, VPS-2-160–PR15R/1XT V, VPS-2-70–PR15R/1XT V, VPS-2-80–PR15R/1XT V, VPS-2-90–PR15R/1XT V, VPS-3-160–PR15R/1XT V, VPS-3-180–PR15R/1XT V, VPS-3-200–PR15R/1XT V, VPS1-16-PR14-R/1XT V

Quick Comparison Table

|

Factors to Consider When Choosing a Hydraulic Pump System

- Consider the following before making a decision:

- Operating Pressure: Select a high pressure hydraulic pump such as the piston type in case of heavy duty.

- Flow Rate Requirement: Make sure that your pump meets the hydraulic requirement of the system.

- Budget and Maintenance: Gear pumps are cheap, and they might not be efficient. Hydraulic piston pumps are more expensive yet long lasting.

- Level of Noise: When noise is of concern, hydraulic vane pump is the most silent.

Guidelines to Choosing the Correct Hydraulic Pump

- It is important to always select pumps of reputable gear pump manufacturers or OEM suppliers.

- Select match pump specifications to your equipment load and environment.

- Seek reliable hydraulic pump systems that have warranty and service.

- Apply manufacturer data sheets in pressure and flow specifications.

Conclusion: Which Pump Wins Under Pressure?

The hydraulic piston pump is the obvious choice, in case your operation requires power, high pressure, and performance. The hydraulic gear pump is reliable and cheap to use in general purposes. And where quiet, smooth performance is required the hydraulic vane pump or rotary vane pump excels.

Regardless of the pump you take, make sure that it is fit to your application and is supplied by reliable vendors. To get quality assurance and unmatched reliability in India, take a look at THM Huade, a well-known brand name in hydraulic systems and high-performance pump solutions.

FAQ’s

Q: What are the main differences between piston, gear, and vane pumps?

Piston pumps can deal with high pressure, gear pumps are simple and robust, and vane pumps are quiet and smooth flowing.

Q: Do piston pumps require more maintenance?

Piston pumps are complex and more maintenance is needed than gear or vane pumps, yes.

Q: How do I choose the right pump for my system?

Compare the specifications of your system in terms of pressure, flow rate, type of application, and budget with a pump.

Q: Can vane pumps handle abrasive fluids?

No, vane pumps do not work well with abrasive fluids because it may lead to quick wear of vanes and the insides.

Q: Which pump type is best for high-pressure applications?

The piston pumps are the most suitable high-pressure pump because of its strong construction and efficiency.