Nowadays, the rapid automation of many processes makes precision not merely a luxury but a necessity. Whether in an industrial machine, automotive system, or aerospace test, knowing the precise position of mechanical parts is essential to establish efficiency and promoting performance. Central to this transformation is the inexpensive linear position sensor. What was once expensive, specialized technology, linear position sensors are now becoming more inexpensive, intelligent, and more general-purpose in application.

In this article today, we are going to discuss the future of sensing technology, the future of low-cost linear position sensors, their types, applications & how they are transforming each & every industry.

What is a Low Cost Linear Position Sensor?

A low cost linear position sensor provides position feedback for displacement, or movement, delivered in a straight line to a control system with linear feedback. This Sensor provides essential data that machines can use to:

- Achieve precise positioning

- Maintain safe operation

- Improve efficiency through automation

Linear position sensors have always been considered expensive to make in high volume, requiring precise manufacturing and complex electronics. But progress in materials, microelectronics, and manufacturing technology had made it competitive with high-quality but crude modeling.

This change allows them to offer a perfect match for scalable deployment — manufacturing, construction, robotics, and hydraulic systems.

The Future of Smart Linear Sensing

Sensing technology of the future will be lean, smart, and compact.

Affordable: Newer manufacturing techniques and global demand are paving way to be accessible for Small to Mid-sized companies, not just limited to big industries.

Intelligence: Today, even low-cost linear position sensors incorporate integrated diagnostics and digital communication capabilities to offer insights versus just data.

Integration: The sensors are designed and manufactured to work with controllers, hydraulic cylinder, and other smart systems to have a more complete setup.

This is revolutionising sectors that previously considered sensor tech too expensive or simply too elaborate.

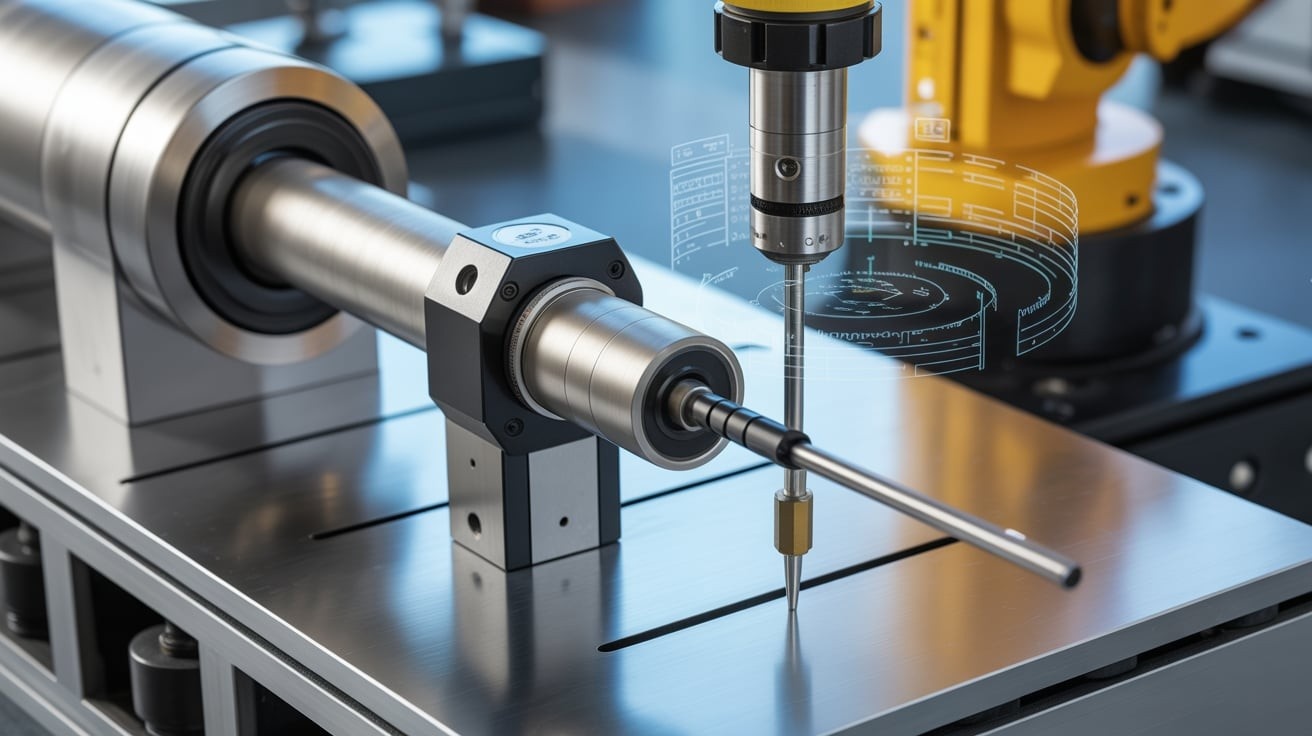

Inductive Linear Position Sensors

Inductive linear position sensors are on the leading edge of linear position sensing technology. These sensors utilize electromagnetic induction to sense displacement:

- The magnetic field is created by a system of coils.

- This field is changed due to the position of a conductive target.

- The functioning of the sensor involves registration of variations, while the resultant measurement is defined in terms of displacement.

Inductive sensors offer several benefits:

- Dirt, oil, and contaminant resistant (great in harsh conditions)

- Non-contact devices mean less wear, which means a long lifespan

- Very high degree of accuracy and reliability

Hence, inductive sensors are indispensable in hydraulic and industrial systems that require both durability and precision.

Role of Sensors in Hydraulic Cylinders

Hydraulic cylinders are at the heart of heavy-duty machinery, responsible for powering various lifting, pushing, and pressing applications in many industries. The hydraulic cylinders must have strong safety measures in place, with the addition of a linear position sensor.

Once the linear position sensor for hydraulic cylinder, it can offer:

- Feedback on the position in real-time: Enabling operators and controllers to understand at any time the actual position of the piston.

- Closed-loop control: The cylinder will be able to correct itself to perform accurately.

- Improved safety: Preventing overextension or collapse to prevent machinery damage or safety hazards.

- Capability to perform predictive maintenance: As sensors track the trends, they will be able to notify users of possible signs of wear or failure.

That’s something that can now finally be practically incorporated with even low-budget linear position sensors. For instance, low-cost sensors improve safety and decrease downtime in construction machinery.

Advantages of Low-Cost Linear Position Sensors

Linear position sensors in the lower cost domain are no longer a compromise as technology evolves. Now they deliver essential advantages for what the industry will require tomorrow:

Affordability: Its affordability empowers mass embrace and an Improved range.

More intelligence: Connecting with Internet of Things (IoT) platforms enables the possibility of real-time data analysis.

Scalability: Low-cost sensors can be deployed across multiple use cases without incurring a significant economic impact.

Technologies compatible: Inductive, capacitive, and magnetostrictive.

Robustness: The sensors withstand challenging environments thanks to their coatings and clever housing.

Future Prospects and Innovations

Smart systems are expected to experience significant growth in the coming decade, and maintaining position sensors will be essential everywhere. Future innovations may include:

Wireless Linear Position Sensors: No more cables, easier integration

Advanced AI-driven Analytics: Predicting Failures (before they happen)

Sensors using Nano-materials: Higher sensitivity with smaller footprint

Energy Harvesting Sensors: These sensors do not rely on power derived from an external source but instead operate independently by harvesting energy from either vibrations within the system or hydraulic sources.

More specifically, over the next decade, we expect linear position sensors for hydraulic cylinder actuation fused with smart sensors to become predominant in industries such as aerospace, automotive testing, robotics, and manufacturing.

Real-Life Applications

This is how low-cost linear position sensors can gain their real-world applications, emphasizing their importance:

Automotive Applications: To also measure suspension travel and crash testing.

Construction Equipment: Cranes, Loaders, And Excavators Ensuring Safe Use

Industrial Automation: Feedback in robotic arms and assembly equipment

Aerospace: Used in flight simulators and actuation systems

Hydraulic Systems: Monitoring the performance of cylinders and other components in heavy equipment

All of these applications rely on accurate, yet cost-effective sensors to scale across systems.

Bottom Line

On the horizon is a new era of balanced sensing technology, fast, smart, and inexpensive. They are now not just being used for basic displacement measurement; in fact, low cost linear position sensors have evolved into intelligent, more integrated, industrial-ready solutions. Inductive linear position sensors with smart integration into the hydraulic cylinder; these linear position sensors for hydraulic cylinders are evolving to create a new future for efficiency, safety, and scalability to no longer be at a premium.

THM Huade provides smart sensor technology to help industries with powerful and durable sensor solutions used to meet future requirements.

FAQs

Q2. Can you use inductive linear position sensors in dirty or rugged environments?

Yes. Unlike many other position sensors, inductive linear position sensors are non-contact, making them immune to the effects of dirt, oil, vibrations, and other environmental conditions. As such, they are also suitable for use as hydraulic cylinders in construction and industrial equipment.

Q3. What is the significance of linear position sensors for hydraulic cylinders?

Hydraulic cylinders equipped with linear position sensors offer accurate displacement measurement, maintain operational safety by preventing overextension, and enable closed-loop control to enhance machine accuracy and performance.

Q4. Are affordable linear position sensors reliable?

Indeed, sensor technology has come a long way, and now affordable sensors perform and last very well. These can be reliable for a variety of industrial and commercial applications.