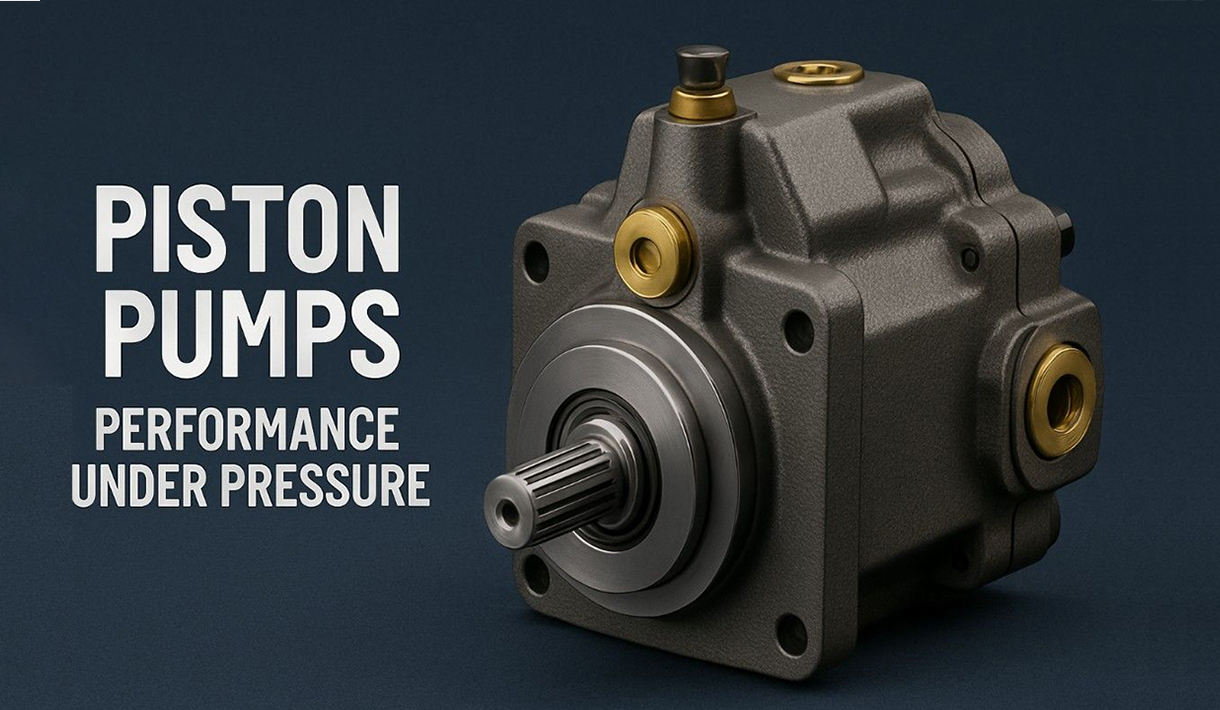

There is no better tool to keep a top performance in harsh working conditions than Reliable hydraulic piston pumps. These high-efficiency components are significant in the industries where there is a need of precise flow control which includes the construction, manufacturing, and automotive industries.

This guide contains all the information you need to know whether you wish to purchase piston pump systems to be used in your project or simply gain more knowledge on how piston pumps perform when subjected to pressure.

Piston Pumps in India Types

The most popular kinds of piston pump in India are as follows:

- Axial Piston Pump – Small and efficient.

- Radial Piston Pump – Applicable to high-pressure and low-velocity applications.

- Variable Displacement Piston Pump – Provides flow control.

- Fixed Displacement Piston Pump – produces fixed flow.

Advantages of Piston Pumps

The advantages of piston pumps extend much beyond the movement of fluids:

- High Pressure Capabilities: It is great at extreme industrial applications.

- Dependable Performance: Stable performance with low failure.

- Compact Design: It is easy to incorporate into different systems.

- Versatility: Good in various industrial uses.

- Energy Efficient: Saves on the total cost of operation.

Such features render high pressure piston pumps suitable to any hydraulic system that requires a strong and continuous operation.

The Advantage of Piston Pumps in High Pressure

1. Good Build Quality

Durable materials are used in the construction of reliable hydraulic piston pumps, and they are made to resist high workloads, pressure surges, and temperature changes.

2. Low Internal Leakage

They have narrow tolerances which minimise energy loss and this makes them have a high volumetric efficiency even at high pressures.

3. Heat Resistance

The majority of the piston pumps produced in India are designed to operate on continuous-duty cycles, so that heat does not compromise performance.

Piston Pumps in Industry

Piston pumps are commonly used industrially, especially in:

- Injection Molding Machinery

- Press Machines

- Construction Equipment

- Agricultural Machinery

- Oil Drilling and Mining

All the industries enjoy the best hydraulic piston pumps since they are durable and precise in the high-pressure conditions.

Some Common Model Codes for Piston Pumps

THM – A2FO – Fixed Displacement Piston Pump

A2FO10/61R-VBB05, A2FO10/61R-VBB06, A2FO107/61R-VBB05, A2FO12/61R-VBB06, A2FO125/61RVBB05, A2FO16/61R-VBB06, A2FO160/61R-VBB05, A2FO180/61R-VBB05, A2FO200/61R-VBB05, A2FO23/61R-VBB05, A2FO28/61RPBB05, A2FO28/61RVBB05, A2FO32/61L-VAB05, A2FO32/61R-VBB05, A2FO45/61R-VBB05, A2FO56/61R-VBB05, A2FO63/61R-VBB05, A2FO80/61R-VBB05, A2FO90/61R.-VBB05

THM – F11 & F12 – Bent Axis Fixed Displacement Motor/Pump

F11-005-MB-CV-K, F11-005-MB-CV-K-000-0000-0T, F11-005-S, F11-010-MB-CV-K-000-0000-00, F11-010-SB-XS-K-285-MUVR-P0, F11-014-SB-WV-X-429-MUVR-P0, F11-019-SB-XS-X-298-MUVR-B0, F12-080-MF-IV-D-000-0000-P0, F12-090-MF-IV-D-000-0000-P0, F12-090-MS-SV-S-000-0000-P0, F12-090-MS-SV-U-000-0000-PT, F12-110-MF-IV-D-000-0000-P0, F12-110-MF-IV-Z-000-0000-P0, F12-110-MF-IV-Z-000-PXXX-P0, F12-110-MS-SV-S-000-0000-P0, F12-110-MS-SV-S-000-PXXX-P0, F12-125-MF-IV-Z-000-0000-P0, F12-125-MS-SV-S-000-0000-P0

THM – A4VSO – Variable Displacement Pump

A4VSO 125 DFE1 /30R-PPB13N00, A4VSO 125 DFR /30R-PPB13N00, A4VSO 125 DFR /30R-VPB13N00, A4VSO 125 DR /30R-FPB13N00, A4VSO 125 DR /30R-PPB13N00, A4VSO 125 DR /30R-PPB13N00 -SO103, A4VSO 125 DR /30R-PPB13N00 E, A4VSO 125 DR /30R-VPB13N00, A4VSO 125 DR /30R-VPB25N00, A4VSO 125 DRG /30R-PPB13N00, A4VSO 125 DRG /30R-PPB25U33, A4VSO 125 DRG /30R-PZB25U33, A4VSO 125 EMA016/30R-PPB13N00, A4VSO 125 HS5EVP/30R-VZB25N00, A4VSO 125 LR2 /30R-PPB13N00, A4VSO 125 LR2 /30R-VPB25U99, A4VSO 125 LR2D /30R-PPB13N00, A4VSO 125 LR2D /30R-VPB13N00, A4VSO 125 LR2G /30R-PPB13N00, A4VSO 125 LR2G /30R-PPB25U99, A4VSO 125 LR2S /30R-PPB25N00, A4VSO 180 DFE1Z /30R-PPB25N00, A4VSO 180 DFE1Z /30R-PZB25U99,

Key Tips for Choosing the Right Piston Pump

You should buy piston pump and remember these tips:

- Pressure Rating: Make sure the pump is the right pressure that you need to operate.

- Displacement Type: You can select fixed and variable displacement types.

- Application Fit: Select the pump to the particular industrial application.

- Brand Reputation: Choose reputable suppliers such as THM Huade.

- Maintenance Accessibility: Models that are easy to maintain are cost and time saving.

What Makes Piston Pump Performance Under Pressure Reliable?

The performance of piston pump at pressure is dependent on:

- Precision-engineered pistons

- High technology sealing systems

- High-strength materials

- Adaptive flow control processes

All these are contributing to the advantages of piston pumps which include long life, steady performance, and high accuracy of output.

Benefits of High Pressure Piston Pumps

What are the advantages of high pressure piston pumps? Let us point them out:

- Increased Flow Rate

- Long Operating Life

- Minimum Wear & Tear

- Suitable under Harsh Working Conditions

- Improved Control and Modulation

Such attributes make piston pump models used in India industries more desirable to purchase as they are made to be used intensively.

How to Maintain Reliable Hydraulic Piston Pumps

To get the best out of your piston pump in terms of performance under pressure, you should observe the following maintenance tips:

- Routine Inspection: Checking of leaks, strange noise, or change of temperature.

- Clean Fluids: Dirty oil will damage the inside.

- Replace Worn Parts: Replace seals, valves, and bearings at the right time.

- Scheduled Servicing: Maintenance as per the manufacturer.

Final Thoughts: The Value of Durable Hydraulic Piston Pumps

In the case of long-term high pressure piston pumps, THM provides high quality products with a global reputation based on different industries. Our hydraulic piston pumps are trusted to perform in the most demanding environments.

The next time you think of your hydraulic setup, select THM HJydraulics and purchase piston pump models that ensure strength, uniformity, and industrial level quality.

Contact THM Hydraulics today to receive professional advice and the appropriate piston pump application to your problem.

FAQ’s

Q 1. What is the performance of a piston pump?

Piston pump is highly efficient, maintains a steady pressure and has a reliable flow rate even in industrial processes that involve heavy work.

Q 2. How does a pressure compensated piston pump work?

It automatically regulates the flow output to provide a steady pressure and makes optimal use of the available energy and avoid overloading.

Q 3. What is the maximum pressure for a piston pump?

The majority of the high-pressure piston pumps have a maximum pressure of 400 bar or more, depending on the model and application.

Q 4. How to set piston pump pressure?

The pressure may be adjusted by an adjusting screw or control valve, according to the manufacturer of the equipment.

Q 5. What is the pulsation of a piston pump?

Pulsation is the variation of pressure in flow, which may be reduced by accumulators or multi-piston designs.