In industrial automation systems, servo motors are necessary in that they provide the precision control, repeatability, and fast response required. Regardless of whether you use it for 3D printer axis movement, CNC machines, or robotics, a servo motor must run smoothly and without failure.

But, like every electro mechanical component, servo motors can get problems with time. In this guide, we will start with common symptoms, then we will go through a step by step troubleshooting guide, a preventive maintenance checklist and answer some of the most common user questions such as – How to troubleshoot servo motor issues in automation systems?

Common Symptoms of Servo Motor Problems

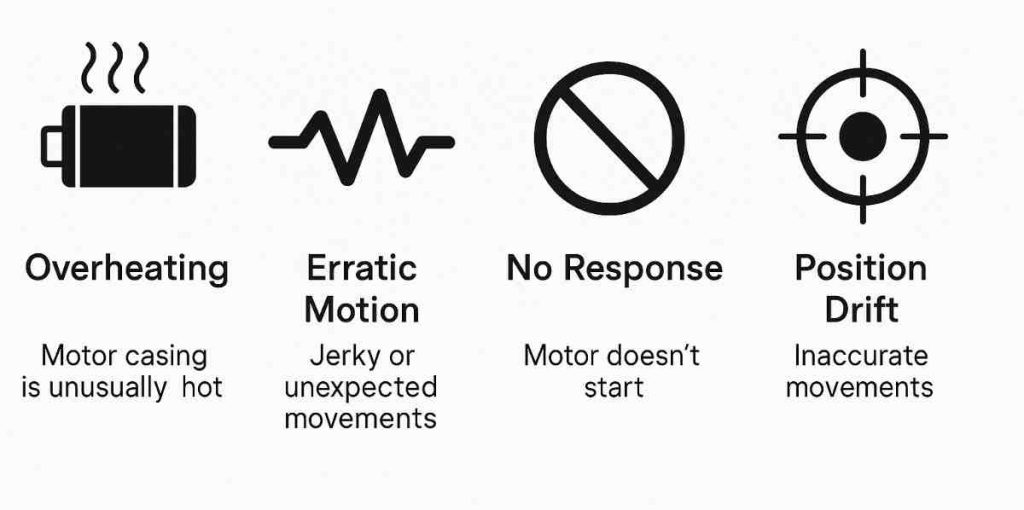

By knowing what to look for, you can save yourself from unplanned downtime and expensive repairs. The most reported issues are:

- Overheating: It shuts down unexpectedly, and the motor feels hot to the touch.

- Erratic motion: Movement that is inconsistent or jerky, resulting in poor machine performance.

- No response: When commanded to move, the servo does not react.

- Vibration or noise: Sounds unusual or shaking during operation.

- Alarm codes or faults: Error messages or blinking fault indicators are shown by controller.

Whether you are using an AC servo motor, a servo motor with built in encoder for precision control, or even a affordable servo motor for CNC machines, these problems can occur.

Step-by-Step Troubleshooting Guide

Step 1: Check Power Supply

Make sure the servo motor gets its proper voltage supply.

Check if cables are disconnected or if the fuses are blown plus if electrical breakers have tripped.

Step 2: Inspect the Servo Drive

Search the display for error messages.

Rephrase the error test after you restart the drive.

Step 3: Test Communication Signals

Make sure the controller (PLC) and the drive system connect correctly.

Replace broken communication wires or set up new connection settings.

Step 4: Examine the Encoder

Look at the encoder to find dirt, damage, or alignment issues.

Test the feedback signal through our diagnostic device to ensure it works correctly.

Step 5: Look for Mechanical Obstruction

Test the motor’s ability to move without a load connected.

When the motor runs smoothly check if mechanical parts are stuck or misaligned.

Step 6: Monitor Overheating

Measure motor surface temperature using an infrared thermometer.

Replace cooling fans or heat sinks when they need cleaning.

Step 7: Evaluate the Control Parameters

Review the servo tuning settings.

Adjust the servo settings once more if they need to match your specific setup.

This structured process works for applications ranging from high torque servo motors for industrial use to servo motor for Arduino projects.

Preventive Maintenance Checklist for Servo Motors

- Regular inspections help avoid most problems before they happen.

- Check for damage to wire connections and their fittings.

- Keep air passages clean and free dust by cleaning fan blades.

- Follow the manufacturer’s instructions when adding lubricant to mechanical parts.

- Calibrate the encoder regularly.

- Monitor for unusual vibrations and noises when the device runs.

- Check and tighten mounting bolts.

- Keep track of motor temperature readings and its error records.

When using servo motors Arduino or compact systems with limited space and thermal management, a well maintained system is especially important.

How Many Types of Servo Motors Are There?

Industrial automation systems use three primary servo motor types:

- AC Servo Motors deliver top efficiency and very precise movement.

- DC Servo Motors work best when you need to control movements at slow speeds.

- Stepper Motors that function like servo motors appear regularly in small automation systems.

There is a type for every use case — best servo motor for robotics applications or servo motors Amazon listings for hobbyists and engineers.

Where Are Servo Motors Used?

Articulated arms, mobile robots, and humanoid bots are some of the robotics.

• Precise spindle and axis movement by CNC Machines.

• 3D Printers – Smooth X, Y, Z movement control.

Industrial Automation – Conveyor systems, packaging lines, assembly machines.

• Surgical tools and diagnostics systems are medical equipment.

When you want a servo motor for 3D printer axis movement or an affordable servo motor for CNC machines, it depends on the torque, size and precision that you need.

How to Troubleshoot Servo Motor Issues in Automation Systems

To troubleshoot effectively:

- Start by examining power supply and electrical connections first.

- Follow the diagnostic tools that the manufacturer offers.

- Your analysis becomes easier when you disconnect the motor from the equipment.

- Use step-by-step methods, not guesswork.

- Keep track of every test you perform and its outcome to help you later.

Conclusion – The Power Behind Precision Control

In modern automation and robotics systems, servo motors are critical. If you require a high torque servo motor for industrial use or a servo motor for CNC machines, it’s important to know the signs of failure, and how to fix them. Keep your motors in good shape, follow the right diagnostic flow, and pick the right kind for your project.

THM Huade is a leading manufacturer and supplier of servo motors in India providing you with reliable products to fulfill your automation needs. If you want more insight or diagrams, check out your motor’s documentation or search for the latest models and Servo Motors price list online.