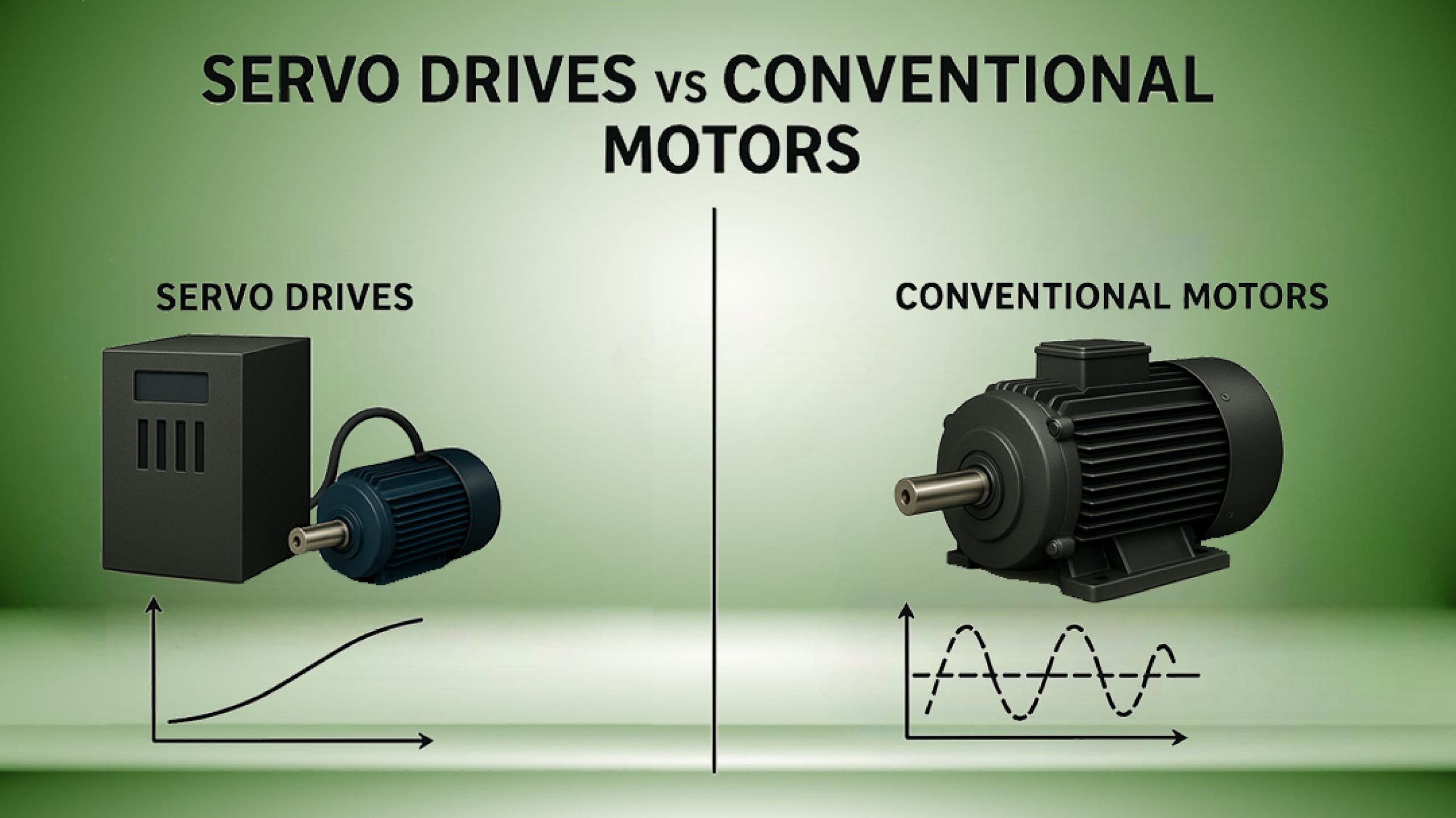

The Servo drive vs conventional motor discussion is more topical in the current manufacturing and automation industries where time is everything. Companies in all industries are looking to solutions to increase efficiency, enhance accuracy and minimize downtimes. At THM, we realize that it is sometimes difficult to decide between servo drive system and different types of conventional motors. This is why we have developed this in depth guide to outline the servo motor benefits and compare the performance to ensure that you make the right decision in regards to your industrial applications.

Understanding the Basics

What is a Servo Drive System?

A servo drive system is a sophisticated motion control system that is used to regulate servo motors. It gets a command signal, amplifies it and sends electrical current to the motor to create a movement with high precision.

Key features include:

- Accurate position, speed, and torque control

- Encoders or sensor feedback loop

- Durability and high performance

What are Conventional Motor Types?

Conventional motor types typically refer to AC induction motors, DC motors, and synchronous motors. These are widely used in industries for basic rotational motion needs.

Common traits include:

- Simple operation

- Cost-effective for low-precision applications

- Limited speed and position control

Advanced Machines Powered by Servo Drive Technology

1. Blow Molding Machine

Makes hollow products using heated plastic and compressed air. It provides accurate mold motion, reduced cycle time, reduced energy consumption, and uniform product quality with a servo drive system which is ideal in packaging, automotive, and consumer goods.

2. Injection Moulding Machine

Makes solid plastic components through injecting melted plastic into moulds. The servo drive technology increases speed, pressure, and positioning control and minimizes waste, saves energy, and increases repeatability in automotive, electronics, and medical manufacturing.

3. Servo Press Machine

Eliminates flywheel/hydraulic systems in favor of a servo drive system to provide position, speed and force accuracy. Provides greater accuracy, programmable press profiles and efficiency, which is ideal in automotive, electronics and metal forming.

Industrial Motor Comparison: Servo vs Conventional Motor

| Feature / Factor | Servo Motors | Conventional Motors |

| Precision | High – Micron-level accuracy | Low – Limited control |

| Speed Control | Good with dynamic adjustments | Limited, often requires external control devices |

| Torque | Consistent across speed range | Drops significantly at higher speeds |

| Energy Efficiency | High – Optimized performance | Moderate – Often wastes power in low-load tasks |

| Maintenance | Lower – Predictive monitoring possible | Higher – Wear and tear on brushes/bearings |

| Cost | Higher initial cost, lower lifetime cost | Lower initial cost, higher long-term cost |

| Best Use Case | Automation, robotics, CNC, precision manufacturing | Fans, pumps, conveyors, basic rotation tasks |

Servo Motor Advantages Over Conventional Motor Types

- Unrivaled Precision- Servo motors are able to attain precision that conventional motors cannot.

- Improved Efficiency- The servo drive system is efficient in utilizing energy in every task.

- Flexible Applications – Servo motors fit in robotics, packaging lines, etc.

- Less Downtime-Predictive maintenance capabilities prevent unexpected failure.

- Constant Torque- Maintain torque at any speed to provide smooth performance.

Why Servo Drives Improve Machine Performance

The use of a servo drive system will increase the overall productivity because:

- Providing real-time feedback control of continual performance

- Enabling rapid changes in the production of goods

- Energy saving through intelligent load management

- Allowing high-speed work without sacrificing precision

Some Common Model Codes for Servo Drive

THM THSD-23-380V-3P-5.5

THM THSD-23-380V-3P-7.5

THM THSD-23-380V-3P-11

THM THSD-23-380V-3P-15

THM THSD-23-380V-3P-18.5

THM THSD-23-380V-3P-22

THM THSD-23-380V-3P-30

THM THSD-23-380V-3P-37

THM THSD-23-380V-3P-45

THM THSD-23-380V-3P-55

THM THSD-23-380V-3P-75

When to Use Conventional Motors Instead

Although servo motors are perfect in precision-oriented industries, the traditional types of motors have not lost their niche:

- Cost-sensitive applications

- Slow-speed, heavy-load work

- Minimal control machinery needs

Servo vs Conventional Motor: The Automation Advantage

Speed, precision, and reliability are the three attributes required by automation systems and servo motors excel over conventional ones. In the case of industries like:

- CNC machining

- 3D printing

- Food processing

- Automatic assembly lines

Servo drive system does not only enhance accuracy but also enhances the consistency of output, which makes it suitable in modern manufacturing.

Tips for Choosing Between a Servo Drive and Conventional Motor

- Determine Your Application Requirements – In the case that precision is a key requirement, then a servo drive system is the way to go.

- Take Operational Costs into consideration, servo motors are more costly in the short run but are less expensive over the long run.

- Verify Speed & Torque Specifications Servo motors hold torque over the range of speeds.

- Maintenance Capability – Servo motors need to be serviced less often.

- Scalability Planing – Servo systems are more flexible in the upgrade to automation.

Final Thoughts: Servo Drives Redefine Efficiency

In the comparison of Servo drive vs conventional motor, we can see that servo technology is ahead in precision, efficiency and automation readiness. Although the traditional types of motors are still functional in simple tasks, industries that seek to grow and increase their productivity should look at changing to a servo drive system.

We offer quality servo solutions to India industries at THM Huade. Call us today and get the right motor system that will suit you.

FAQs

Q 1. Can servo motors replace conventional motors?

Servo motors can indeed be used as a substitute to the traditional type of motors in most situations, particularly where high precision, speed regulation and automation is needed. But in low cost, simple applications, conventional motors can still be applicable.

Q 2. How do servo drives improve machine performance?

Servo drive system has the advantage of controlling speed, torque and positioning more precisely resulting in improved product quality, minimized wastage, and accelerated production.

Q 3. Are servo drives more expensive than regular motors?

Yes, first they are more expensive. Nevertheless, the benefits of servo motor, such as energy efficiency, less downtime, and higher productivity, may prove to be more economical in the long-term perspective.

Q 4. What makes a servo drive ideal for automation?

Its capability to give precise motion control, immediate response to feedback and its ability to integrate with current industrial automation systems make the servo drive system the most appropriate system to use in automation.

Q 5. Do conventional motors offer speed control like servo drives?

Not exactly. Speed control of conventional motors may need external controllers whereas servo motors include built-in systems to control the speed accurately.

Q 6. How do I choose between a servo drive and a conventional motor?

Determine the accuracy, speed, and torque requirements and budget of your application. Servo motors are preferable to high-tech, precision-oriented processes.