Hydraulic systems are the industry’s powerhouses, offering unparalleled force and accuracy in operations. The hydraulic flow control valve is at the core of these systems. This critical part controls the hydraulic fluid flow throughout the machinery and helps control the efficiency of operation. However, hydraulic flow valves, like any other mechanical component, can experience problems.

This blog will dive into a few common issues encountered in hydraulic systems and offer a practical solution for keeping your hydraulic systems up and running.

Importance of Hydraulic Flow Control Valve

The valve controls the hydraulic flow to control the hydraulic fluid in the hydraulic system. It ensures that the correct volume of fluid is delivered to authorized actuators with the same pressure and speed. Flow control is essential in machinery because, without it, machinery can operate in an erratic motion, which reduces effective work and the deterioration of some parts. Hydraulic flow control valves are used for accurately controlling them, so they are necessary for applications from construction machines to factories.

Troubleshooting of Flow Control Valve Hydraulic

Inconsistent Flow Rates

One of the most prevalent problems is the inconsistency of flow rates. These can all occur for various reasons, such as dirt inside the fluid, worn-out valve parts, or the valve being adjusted incorrectly. The first step in the troubleshooting process for this matter is to inspect the hydraulic fluid for contamination. If the fluid is contaminated, it will clog the valve and cause flow disruption. Change the fluid and filter to have a clean system.

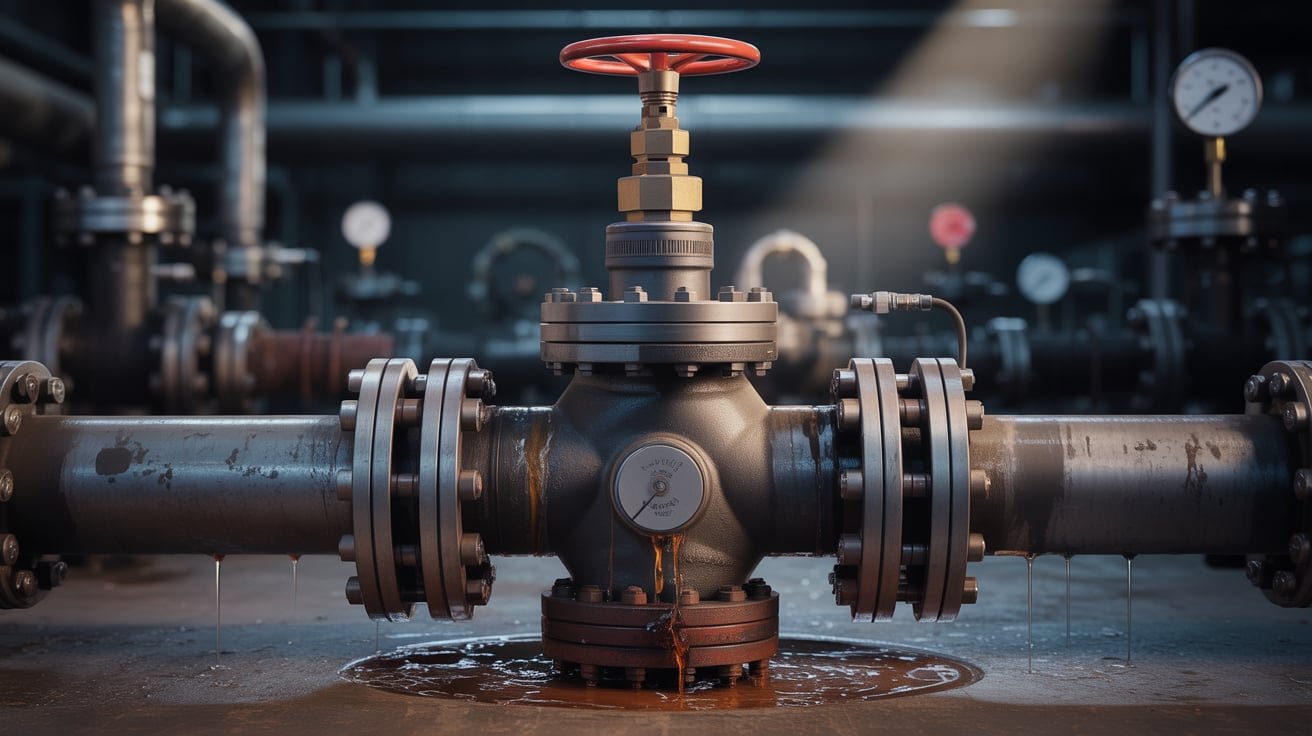

Leaks and Seals

Flow control valve hydraulic leaks can result in fluid loss and reduced efficiency. Inspect seals and gaskets for wear and tear. If you find any faults, make sure you replace them. Furthermore, make sure the valve is correctly installed and tightened to avoid leaks.

Valve Stiction

One of the other classic failure modes is valve stiction, which can prevent the valve from opening or closing by sticking in one position. Causes of this may vary from corrosion, debris, or lack of lubrication. Solution: Clean the valve, add lube, and check for moisture. In case the issue is not resolved, try reinstalling the valve.

Incorrect Valve Adjustment

Incorrect hydraulic valve adjustment will make work inefficient. Verify that the valve has been adjusted per the manufacturer’s specifications. Make micro-adjustments using a calibrated instrument. To maintain optimum performance, check the valve settings at regular intervals.

In-Depth Troubleshooting Guide

Inspection Process (Step-by-Step)

If you are experiencing problems with your hydraulic flow control valves, you will need to troubleshoot them, which means you will want to be systematic about your approach. Begin by inspecting the valve with your eyes. Look for any leaks around the seals and gaskets and corrosion on the valve body.

The next step is to check the oil for impurities. Dirty fluid can clog the valve and disrupt the flow. If the fluid is dirty, change it and the filter.

Cleaning and Maintenance

It is important to clean your hydraulic flow valve regularly. Start by removing the valve from the system it is connected to and any other external parts. After removing debris and contaminants, utilize an appropriate cleaning solution.

Note: Pay extra attention to valve internals; these are the areas that can build up quite easily. Once all the cleaning is done, make sure to wash the valve properly and then dry it completely before reassembling.

Lubrication and Sealing

Adequate lubrication is important to prevent wear and keep the system running smoothly. Lubricate the sliding components of the extreme-quality lubricant valve. Finally, check all the seals and gaskets. If you see any signs of wear, replace them immediately. Sealing is also performed to avoid fluid loss and ensure operating pressure in the system.

Calibration and Adjustment

Proper calibration is a must for best performance. Adjust the valve with a calibrated device according to specifications. Be sure to set the hydraulic valve adjustment for the flow rate that your system requires.

You should check the settings regularly on your laptop to ensure that performance remains as expected. If you are uncertain about the right settings, refer to the technical manual for that valve or contact the manufacturer for help.

Maintenance at a Higher Level

However, you can utilize a preventive maintenance schedule that will help you minimize the chances of the hydraulic flow control valve problems occurring. Plan periodic inspections and maintenance tasks so your system works like a charm. This is a recommended maintenance schedule:

Inspection Monthly: Look for leaks, wear and tear, and debris. Inspect seals and gaskets.

Fluid Checks: Quarterly, clean all hydraulic fluid and filters.

Lubrication: Moving parts need to be covered with some lubricant in order to ensure wear and tear won’t occur.

Once a Year Calibration: Ensure settings on the hydraulic flow valve are with the necessary adjustments.

Training and Documentation

Make sure that your team is well-trained in hydraulic system maintenance. Include training on inspections, cleaning, lubrication, and calibration. Document all maintenance activities in detail. This information can be helpful when troubleshooting and keeping performance constant.

Moreover, documenting problems and their respective solutions may help detect recurring issues; only now can you engage in targeted intervention.

Troubleshooting Tips

To pinpoint issues, use pressure gauges before and after the valve. Any major drop suggests blockage or internal wear. A flow meter helps identify if the valve is stuck or if the flow is inconsistent with the system’s demand.

Temperature has a big impact—high heat thins fluid and damages seals, while cold thickens it, causing sluggish valve response. Use stable-viscosity hydraulic oil and monitor system cooling.

Know when to repair or replace. Replace valves that are cracked, heavily corroded, or frequently sticking. If it’s a minor clog or seal issue, cleaning and lubrication may be enough.

Conclusion

Hydraulic flow low-control valves are used in most hydraulic systems. Maintenance can keep your system working smoothly and help you understand and address problems. Now, always check the valve, keep the fluid clean, and lubricate your valve. By using these practices, you can save on expensive repairs and regular downtime. By keeping your hydraulic flow control valve running optimally, you can enjoy dependable machinery performance.

Check out our store, THM Haude, to find durable and reliable hydraulic equipment.

FAQs

What is the stiction of valves in hydraulic systems?

Corrosion, dirt, and debris between the valve surface, as well as insufficient lubrication, can all cause valve stiction. To avoid stiction, keep the hydraulic fluid clean and the valve lubricated. Cleaning and upkeep allow the valve to function properly.

How do I adjust a hydraulic flow control valve?

Each hydraulic flow control valve needs to be set up precisely. Have a calibrated tool and adjust it according to the manufacturer's specifications, etc. Check the valve, making sure it selects the flow rate your system needs. Make sure you check those settings on a regular basis to keep the best performance going.

How to replace hydraulic fluid that contains contaminants?

By all means, if you find debris in your hydraulic fluid, take action. Change the fluid and filter to remove impurities. Look around the system for potential sources of debris and resolve them to prevent recurrence. The fluid must be clean for the valve to work properly.