For mobile machinery applications, efficiency and dependability are a must. The GFT planetary gearbox, which seamlessly integrates both, is one of the essential elements. The T-series gearboxes are designed for a compact space envelope, but they also have a high torque capacity with long service life, making the drive suitable for heavy-duty mobile equipment applications.

Work with construction machines, mining equipment, or other large-scale industrial applications. Understanding the operation of a GFT planetary gearbox can help you select the ideal system and ensure optimal performance.

What Is a GFT Planetary Gearbox?

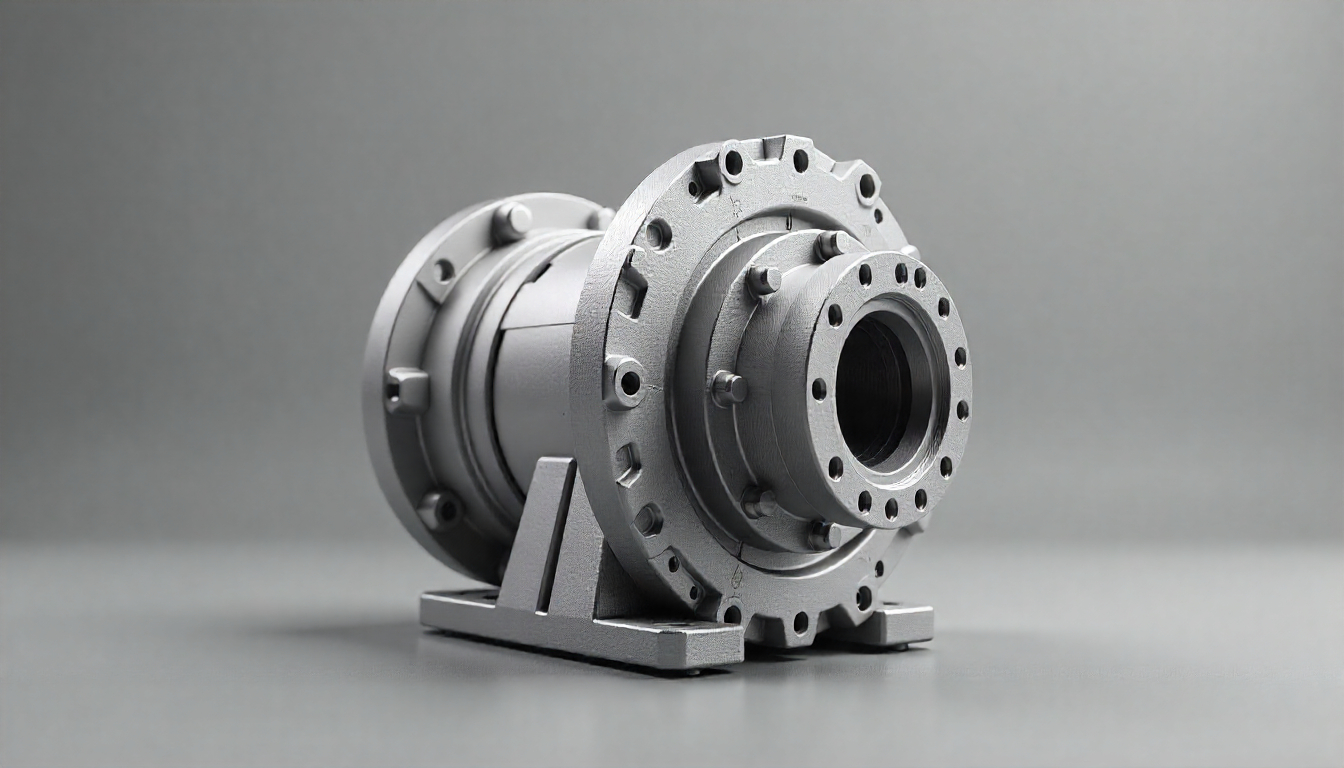

A GFT planetary gearbox transfers the drive energy from a motor to the driver mechanism through planetary gear arrangements. The name gets modified due to the special arrangement of the gear inside it. This involves a set of planet gears that orbit around a central sun gear; each gear will rotate in an outer ring gear. The planets are attached to a carrier, from which torque is delivered to the output shaft.

It distributes the load over multiple gears, which allows the gearbox to manage high torque in a very small form factor. It is one reason that makes GFT planetary gearboxes well suited for mobile equipment where the availability of space and mass are limited, but significant power is needed.

How a GFT Planetary Gearbox Works in Mobile Equipment?

A GFT planetary gearbox works on a very straightforward principle, but it is incredibly effective. When the motor drives the sun gear, the planet gears move accordingly. In turn, the planet’s gears roll inside the ring to get rid of the body. This combination allows for a torque multiplication and a speed reduction, which is perfect for heavy machinery that requires high force output at low speeds.

The benefit of this, however, is the lengths you can go to achieve various gear ratios with minimal space, especially in the same housing. According to the specification of GFT planetary gearbox, manufacturers can design planetary gearboxes in different capacities of load, input speed, and output torque.

In mobile machinery, the gearbox is commonly combined with the final drive. The GFT unit operates together with compact hydraulic motors to harness hydraulic energy to mechanical drives, providing the required torque to drive the machine’s tracks or wheels.

GFT Planetary Gearbox Specification: Key Features to Consider

Before choosing a gearbox, review of the gearbox planetary specification to ensure compatibility with your equipment. GFT planetary gearbox specification may change in the various models, but here are some of the variables you need to keep an eye on:

Output torque capacity: This refers to the amount of turning force the gearbox can support. Higher torque ratings are needed for heavy-duty applications.

Gear Ratios: Available in a wide range, these can be configured for speed or torque.

Load Capacity: This refers to the amount of load and stress the gearbox can handle without performance degradation.

Mounting Types: Based on your setup, the gearbox may come in a variety of configurations, including flange-mounted or shaft-mounted.

Sealing and Protection: GFT gearboxes are frequently equipped with advanced sealing mechanisms that guard against dust, water, and contaminants, enabling use in extreme working conditions.

This level of GFT planetary gearbox specification knowledge ensures the gearbox will be reliable under the loads and requirements in your application.

Common GFT Final Drive Gearbox Applications

The GFT final drive gearbox application is over a wide spectrum. This is usually common in mobile tracked equipment where power needs to be transmitted efficiently to the tracks or the wheels. Common GFT final drive gearbox application include:

Excavators: Giving strength to move heavy objects and transport them across challenging terrain.

Crawler Cranes: Designed to give accurate movement control while lifting.

Drilling Rigs: Provides reliable and robust circularity for challenging ground drilling.

Mining Machines: Reliable performance under extreme conditions.

Forestry Gear: Assisting machines in overcoming rough terrains while transporting heavy loads.

The GFT gearbox is a fundamental component providing mobility, efficiency, and durability in each of these applications.

Advantages of Using a GFT Planetary Gearbox

Operators and manufacturers have a few reasons to choose a GFT planetary gearbox as the drive for heavy-duty mobile machines:

High Torque Density: The planetary configuration distributes the load over several gears, allowing the gearbox to generate high torque in a compact package.

Small Form Factor: Where space is a constraint for mobile equipment.

Higher-speed Reduction: Less energy loss than other gear types.

Durability: Designed to withstand extreme conditions in dust, mud, water, and high-impact environments.

For Non-Stop Working Days: A good GFT-designed gearbox reduces downtime by extending the service intervals virtually.

Such advantages directly result in increased operator efficiency and lower equipment operating costs.

When to Choose a Used GFT Planetary Gearbox for Heavy Equipment?

A used GFT planetary gearbox for heavy equipment can provide the same level of performance as a new gearbox, however, and invest way less money. Reliable suppliers often offer used units that are refurbished and tested for operational condition. Unfortunately, high-quality manufacturing demands a hefty price tag for both the original equipment and the production of spare parts; however, a used gearbox can prove to be just the ticket for those businesses trying to reduce capital expenditure whilst not skimping when it comes to performance.

Things to consider when buying a second-hand gearbox!!

- Check the service history if it comes with one.

- Check for wear, especially on gear teeth and bearings.

- Make sure that the lubricant and its seals are healthy.

- Fit into the specs of your equipment.

Maintenance Tips for Long-Term Reliability

With the right care, a used GFT gearbox can serve for years. A GFT gearbox has a longer lifespan if maintained properly.

The following is regular maintenance, which is essential for extending the life and functionality of a used GFT planetary gearbox for heavy equipment:

Lubrication: Use the proper type of oil and change it at specified intervals.

Seals Inspection: Make sure seals are intact to avoid any contaminants from entering the gearbox.

Temperature Monitoring: Operating temperatures must be monitored because if gears and bearings get too hot, they can be permanently damaged.

Load Monitoring: Prevent overloading of the gearbox to prevent premature wear.

All this preventive maintenance will ensure that the vehicle operates smoothly and will not break down painfully to the pocket.

Conclusion

The GFT planetary gearbox is a high-performance, compact, low-weight & high-torque transmission, and is one of the essential core technologies for many mobile equipment applications. From excavators, cranes, mining machines, to drilling rigs, these machines need the right gearbox to achieve optimum running efficiency.

Buying tips for whether the GFT planetary gearbox specification is just right, because the GFT final drive gearbox application uses either a used GFT planetary gearbox for sale, which appears to be quality heavy equipment, to help you in your purchasing decisions.

Select a recognized brand for reliable performance and durability. These planetary gearboxes are known for their durability, precision engineering, and are competent for tough industrial standards and quality putups, along with GFT planetary gearboxes by THM Huade.

FAQs

Is my current gearbox able to install a used GFT planetary gearbox for heavy equipment?

Yes, you can actually replace it with a used gearbox if it meets all the requirements of your specification and is perfectly functional. It can be a choice within your budget.

Where is the GFT final drive gearbox used?

Commonly used in construction, mining, forestry, and other industries where heavily loaded tracked or wheeled gearboxes need highly durable and reliable torque transmission.

How often should I service my GFT planetary gearbox?

Based on your conditions of usage, the service intervals will vary, but generally, you need to monitor your lubrication levels and seal inspections every couple of hundred working hours, as per manufacturer maintenance specifications.