Hydraulic Pump is an important part of the machinery used in various industries such as construction, manufacturing, and agriculture. When you are either upgrading a system or buying a hydraulic pump the first time, it is important to know what makes a pump reliable. This hydraulic pump purchasing guide identifies the dependable hydraulic pump features you ought to look into in order to get long-term performance.

1. Build Quality and Material Durability

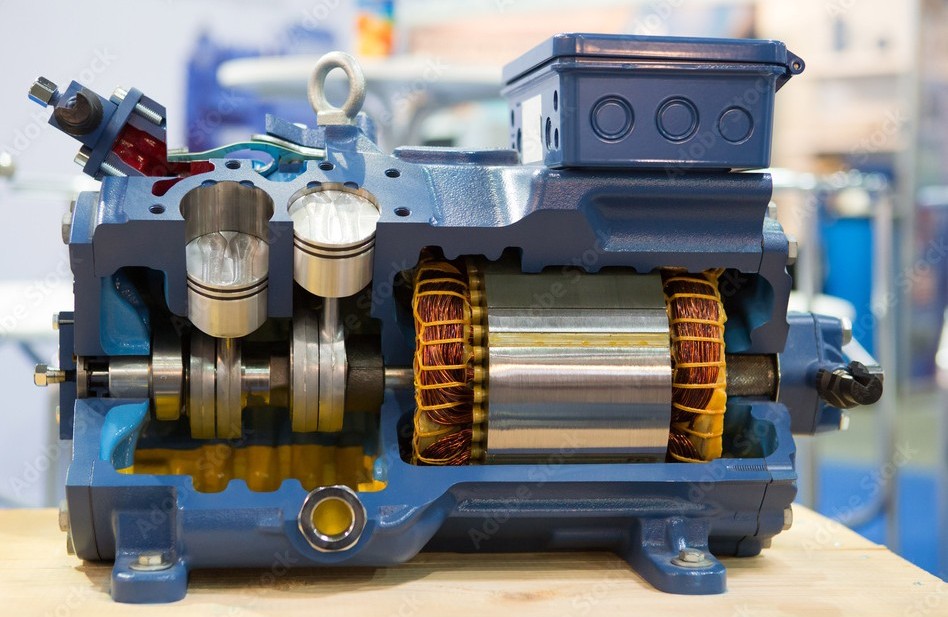

The quality of construction is the first and the foremost determinant of a durable hydraulic pump system.

- Longer life is provided by high grade materials such as cast iron or steel.

- The corrosion resistant coatings are more superior in extreme conditions.

- Pumps that have precision-machined parts have longer life and low maintenance.

Tip: If you are purchasing a hydraulic pump, in India, make sure it is of ISO quality or similar quality.

2. Design Efficiency and Performance Consistency

Any good hydraulic pumps should be able to provide stable performance with fluctuating loads and operating hours.

- Select an appropriate design (axial, gear, vane or piston) to fit your application.

- Seek energy saving and flow rate efficiency.

- Reliability is increased by internal design that minimizes heat and friction.

Important: Efficiency is a critical factor that influences the fuel consumption and quality of output, which is essential to long-term hydraulic pump products.

3. Fit with Your Hydraulic System

The selection of a quality hydraulics pump also includes its compatibility with the other system parts.

- Make sure that your pressure ratings are consistent with your other hydraulic system.

- Check the size of ports and mounting possibilities.

- Take into consideration pumps which can be easily connected to servo systems or automation modules.

Tip: Do not forget to look at the technical datasheet of the manufacturer.

4. Maintenance Requirements and Serviceability

A good hydraulic pump is one whose design is easy to maintain and easy to carry out maintenance.

- Pumps that have easy-access parts minimize downtime.

- It is essential to have the availability of spare parts locally or through distributors.

- The biggest plus points are the user manuals, service videos, and the assistance of experts.

Recommendation: Get pumps of standard fittings and seals to ease repair work.

5. Successful Track Record and Brand Name

Reliability of products can be reflected in brand history.

- Well established brands provide tested and certified pumps.

- There is confidence through user reviews and testimonials.

- Select the pumps which are backed by warranty and after sales service.

In purchasing hydraulic pump in India, make sure you consider the brands that produce the best hydraulic pump to use in heavy duty.

6. Flexibility to extreme working conditions

The pumps that work in harsh conditions require special considerations:

- High-temperature tolerance

- Vibration and shock resistance

- Capability of dealing with abrasive or viscous fluids

Note: These are some of the factors that influence the reliability of hydraulic pumps, which in most cases are ignored yet they are very important in mining, oil & gas, and construction industries.

Pro Buying Tips: Choosing a Reliable Hydraulic Pumps

These are some of the other tips to make the correct choice:

- Before selection, know your pressure and flow requirements of your system

- Select the appropriate type of pump (gear, vane or piston pump) depending on the application

- Compare the energy use to save on the long-term costs

- Assure product certifications

- Contrast warranties and after sales services

This guide to buying a hydraulics pump will help you make a good purchase and save the cost of replacement in the future.

Conclusion -Why Reliability is Important in a Hydraulic Pumps

Reliability of a hydraulic pump is not negotiable in any industrial set up. Downtime, repair, or replacement may cost much more than the purchase of a quality unit. These six important aspects of design, durability, etc. can help you achieve the best performance and low rate of breakdowns.

In order to have credible performance, longevity, and professional assistance, one should rely on such brands as THM Huade Contact that offers long-term hydraulic pump solutions to any application.

In case you need assistance in the selection of the right product or have any questions, please contact us. This guide can become your guide whether you need to find a hydraulic pump on sale, cheap hydraulic pumps, or a piece of advice on how to select a good hydraulic pump.

FAQ’s

Q: 1 What are the key factors that determine the reliability of a hydraulic pump?

The main factors that influence the reliability of hydraulic pumps are pump design, the quality of the build, maintenance, cleanliness of fluid and proper sizing.

Q: 2 Is it worth investing in a premium pump for better reliability?

Yes, high quality hydraulic pumps have a longer life, higher efficiency and less downtime, and that makes them a wise long term investment.

Q: 3 How often should a hydraulic pump be serviced for optimal reliability?

Services are dependent on use but regular checks after 500-1000 operating hours can keep a service running well.

Q: 4 Why is material selection important in hydraulic pump reliability?

Good materials are wear resistant, corrosion and pressure fatigue resistant, and this directly impacts the strength and performance of the pump.

Q: 5 What signs indicate that a hydraulic pump is becoming unreliable?

The usual symptoms of pump wear or failure are noise, overheating, low pressure, fluid contamination, or slowness.